Precision thermal control is the cornerstone of synthesizing electronic-grade materials. High-performance heat treatment equipment is essential for 900°C calcination because it creates the rigorously stable and uniform temperature field required for complex chemical conversions. Without this precision, it is impossible to ensure the complete oxidation and decomposition processes necessary to achieve the high purity standards of electronic-grade copper oxide.

Achieving electronic-grade copper oxide requires more than just reaching 900°C; it demands a flawless thermal environment. High-performance equipment guarantees the uniformity necessary to eliminate impurities, perfect the crystal structure, and secure purity levels exceeding 99.20%.

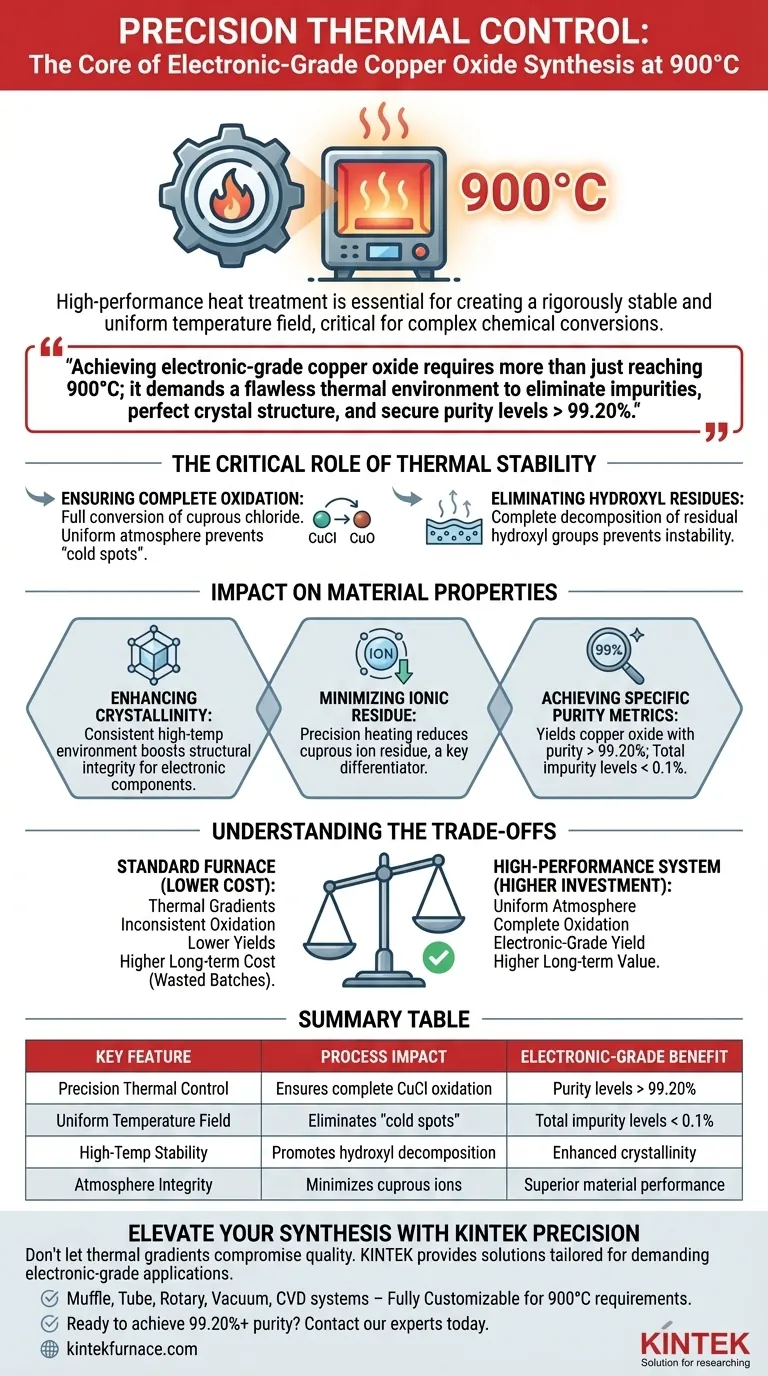

The Critical Role of Thermal Stability

Ensuring Complete Oxidation

The primary chemical objective at 900°C is the full conversion of precursors into copper oxide.

High-performance equipment ensures that cuprous chloride is fully oxidized. A uniform atmosphere prevents "cold spots" that would otherwise leave unreacted material in the batch.

Eliminating Hydroxyl Residues

Beyond oxidation, the process must strip away volatile impurities.

The equipment promotes the complete decomposition of residual hydroxyl groups. This is critical for preventing chemical instability in the final application.

Impact on Material Properties

Enhancing Crystallinity

The stability of the temperature field directly influences the physical structure of the material.

A consistent high-temperature environment significantly enhances product crystallinity. This structural integrity is vital for the performance of copper oxide in electronic components.

Minimizing Ionic Residue

Precision heating allows for the strict control of ionic impurities.

The process specifically reduces cuprous ion residue. This reduction is the key differentiator between standard industrial copper and electronic-grade material.

Achieving Specific Purity Metrics

The ultimate output of using high-performance equipment is quantifiable quality.

This process yields copper oxide with a purity exceeding 99.20%. Furthermore, it ensures total impurity levels are kept below 0.1%, meeting stringent electronic standards.

Understanding the Trade-offs

Equipment Cost vs. Product Value

High-performance heat treatment systems represent a significant capital investment compared to standard industrial furnaces.

However, relying on lower-grade equipment introduces thermal gradients. This leads to inconsistent oxidation and lower yields of electronic-grade material, which can be more costly in the long run due to wasted batches.

Making the Right Choice for Your Goal

To select the correct processing strategy, align your equipment capabilities with your specific purity requirements:

- If your primary focus is maximizing purity: Ensure your equipment provides a uniform atmosphere to guarantee cuprous chloride is fully oxidized and impurity levels remain below 0.1%.

- If your primary focus is structural integrity: Prioritize thermal stability at 900°C to drive the decomposition of hydroxyl groups and maximize product crystallinity.

Precision heat treatment is not merely a manufacturing step; it is the defining factor that elevates copper oxide from a raw commodity to a high-value electronic component.

Summary Table:

| Key Feature | Process Impact | Electronic-Grade Benefit |

|---|---|---|

| Precision Thermal Control | Ensures complete cuprous chloride oxidation | Purity levels exceeding 99.20% |

| Uniform Temperature Field | Eliminates "cold spots" and unreacted material | Total impurity levels < 0.1% |

| High-Temp Stability | Promotes full decomposition of hydroxyl groups | Enhanced product crystallinity |

| Atmosphere Integrity | Minimizes residual cuprous ions | Superior material performance |

Elevate Your Material Synthesis with KINTEK Precision

Don't let thermal gradients compromise your product quality. At KINTEK, we specialize in providing high-performance heat treatment solutions tailored for the most demanding electronic-grade applications. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique 900°C calcination requirements.

Ready to achieve 99.20%+ purity consistently? Contact our technical experts today to design a thermal environment that guarantees stability, uniformity, and excellence for your laboratory or production line.

Visual Guide

References

- Dengliang He, Shishan Xue. Integrated Alkali Gradient pH Control Purification of Acidic Copper-Containing Etching Waste Solution and Cu2(OH)3Cl Conversion-Calcination Process for High-Purity CuO. DOI: 10.3390/pr13092807

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How do lab high-temp furnaces and air quenching coordinate in o-LISO synthesis? Master the Thermal Transition

- How does the "Flux Melting" process in MOF glass preparation utilize heating equipment? Low-Temp MOF Vitrification

- What is the function of a drying oven in the post-treatment process of Ni and Zn-doped MgO nanoparticles?

- How does a laboratory furnace operate? Master Heating Principles for Your Lab

- How does a sealed ceramic boat impact SPAN sulfur content? Unlock 53.62% Retention for High-Energy Cathodes

- What is the function of a forced convection drying oven for silica xerogel? Achieve Superior Porosity and Stability

- What are the advantages of using a vacuum drying oven for BiVO4/COF composite photoanodes? Preserve Material Integrity

- Why is an incubator required for VP-FSCM? Master Curing Controls for Superior Soil Solidification Results