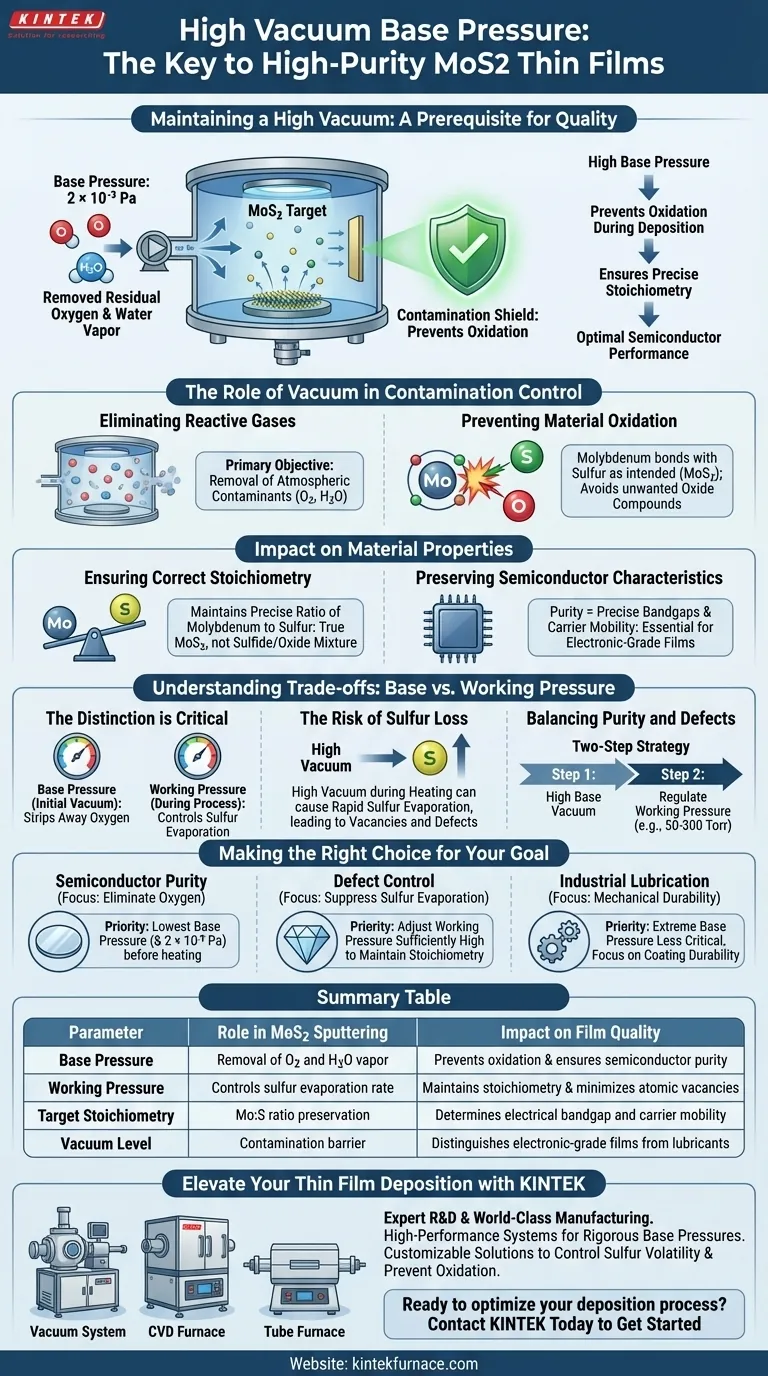

Maintaining a high vacuum base pressure is the fundamental prerequisite for depositing high-purity Molybdenum Disulfide (MoS2) thin films. By achieving a vacuum level as low as $2 \times 10^{-3}$ Pa, you effectively evacuate residual oxygen and water vapor from the sputtering chamber. This step is non-negotiable for preventing oxidation during deposition and ensuring the film retains the precise stoichiometry required for optimal semiconductor performance.

Core Takeaway The quality of an MoS2 thin film is defined before deposition even begins. A high vacuum base pressure acts as a shield against environmental contamination, ensuring that the resulting material is a pure semiconductor rather than a degraded oxide.

The Role of Vacuum in Contamination Control

Eliminating Reactive Gases

The primary objective of establishing a high vacuum base pressure (often around $2 \times 10^{-3}$ Pa) is the removal of atmospheric contaminants.

The most critical enemies of MoS2 deposition are residual oxygen and water vapor. If these gases remain in the chamber, they do not simply float passively; they actively react with the source materials.

Preventing Material Oxidation

During the sputtering process, atoms are ejected from the target material in a highly energetic state.

In this state, Molybdenum is highly susceptible to reacting with any lingering oxygen. A high vacuum ensures that the Molybdenum bonds with Sulfur as intended, rather than oxidizing to form unwanted compounds that degrade the film's structure.

Impact on Material Properties

Ensuring Correct Stoichiometry

Stoichiometry refers to the precise quantitative relationship between the elements in the film—specifically, the ratio of Molybdenum to Sulfur.

High base pressure is essential to maintain this ratio. By removing competing reactants (like oxygen), you ensure that the deposited film remains true Molybdenum Disulfide, rather than a compromised mixture of sulfides and oxides.

Preserving Semiconductor Characteristics

The electrical properties of MoS2 are heavily dependent on its purity.

When oxidation is prevented through proper vacuum protocols, the film maintains the correct semiconductor characteristics. This is vital for applications requiring precise bandgaps and carrier mobility, distinguishing electronic-grade films from lower-quality industrial coatings used for lubrication.

Understanding the Trade-offs: Base vs. Working Pressure

The Distinction is Critical

While high base pressure is essential for purity, it is not the only pressure variable that matters. You must distinguish between the initial vacuum (base pressure) and the pressure during the actual process (working pressure).

The Risk of Sulfur Loss

Once deposition or sulfidation begins, maintaining a high vacuum can sometimes work against you if not managed correctly regarding sulfur volatility.

As noted in sulfurization processes, higher working pressures (e.g., 50–300 Torr) are often required to control the evaporation rate of sulfur. If the environment is too rarefied during the heating phase, sulfur may evaporate too quickly, leading to sulfur vacancies and defects.

Balancing Purity and Defects

Therefore, the ideal process involves a two-step pressure strategy.

You need a high vacuum base to strip away oxygen initially. However, you must subsequently regulate the working pressure to ensure there is an adequate sulfur source to passivate defects and control the conductivity type (transitioning from defect-heavy n-type to high-quality p-type).

Making the Right Choice for Your Goal

To maximize the quality of your MoS2 thin films, align your vacuum strategy with your specific performance requirements:

- If your primary focus is Semiconductor Purity: Prioritize achieving the lowest possible base pressure ($< 2 \times 10^{-3}$ Pa) to eliminate all traces of oxygen and water vapor before heating begins.

- If your primary focus is Defect Control: Ensure that after establishing a high base vacuum, you adjust the working pressure sufficiently high to suppress sulfur evaporation and maintain stoichiometry.

- If your primary focus is Industrial Lubrication: While vacuum is important for adhesion, extreme semiconductor-grade base pressures may be less critical compared to the mechanical durability of the coating.

Success in MoS2 sputtering relies on a pristine starting environment followed by precise pressure regulation to protect the film's chemical composition.

Summary Table:

| Parameter | Role in MoS2 Sputtering | Impact on Film Quality |

|---|---|---|

| Base Pressure | Removal of O2 and H2O vapor | Prevents oxidation & ensures semiconductor purity |

| Working Pressure | Controls sulfur evaporation rate | Maintains stoichiometry & minimizes atomic vacancies |

| Target Stoichiometry | Mo:S ratio preservation | Determines electrical bandgap and carrier mobility |

| Vacuum Level | Contamination barrier | Distinguishes electronic-grade films from lubricants |

Elevate Your Thin Film Deposition with KINTEK

Precision in Molybdenum Disulfide (MoS2) sputtering begins with the right environment. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Vacuum, CVD, and Tube furnace systems specifically designed to achieve the rigorous base pressures required for semiconductor-grade thin films.

Whether you need a standard setup or a fully customizable solution to control sulfur volatility and prevent oxidation, our technical team is ready to support your unique research needs. Ensure your materials meet the highest standards of purity and stoichiometry.

Ready to optimize your deposition process? Contact KINTEK Today to Get Started

Visual Guide

References

- Irasani Rahayu, Melania Suweni Muntini. Effect of Annealing Techniques on the Thermoelectric Properties of Molybdenum Disulfide Thin Films Prepared by RF Sputtering. DOI: 10.1088/1742-6596/3139/1/012035

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What effect does a laboratory hot plate have on 2D material heterostructures? Enhancing Interlayer Bonding Quality

- What is the function of the electric arc furnace in the production of UMG-Si? Powering Silicon Transformation

- Why is the use of a vacuum oven mandatory for drying Ti3C2Tx MXene precursors? Protect Your Advanced 2D Materials

- What is the function of an inert gas supply system in black liquor pyrolysis? Achieve Precise Atmospheric Control

- What is the function of a fixed-bed catalytic reactor in ex situ CHP? Optimize Your Bio-oil Quality Today

- What is the purpose of using a high-vacuum pump system for NiTi thin films? Ensure Pure Stoichiometry & Performance

- What is the difference between traditional metallurgical processes and powder metallurgy? Choose the Right Metal Process

- What is the necessity of carbon coating for silicon anodes? Engineering Durability for High-Performance Batteries