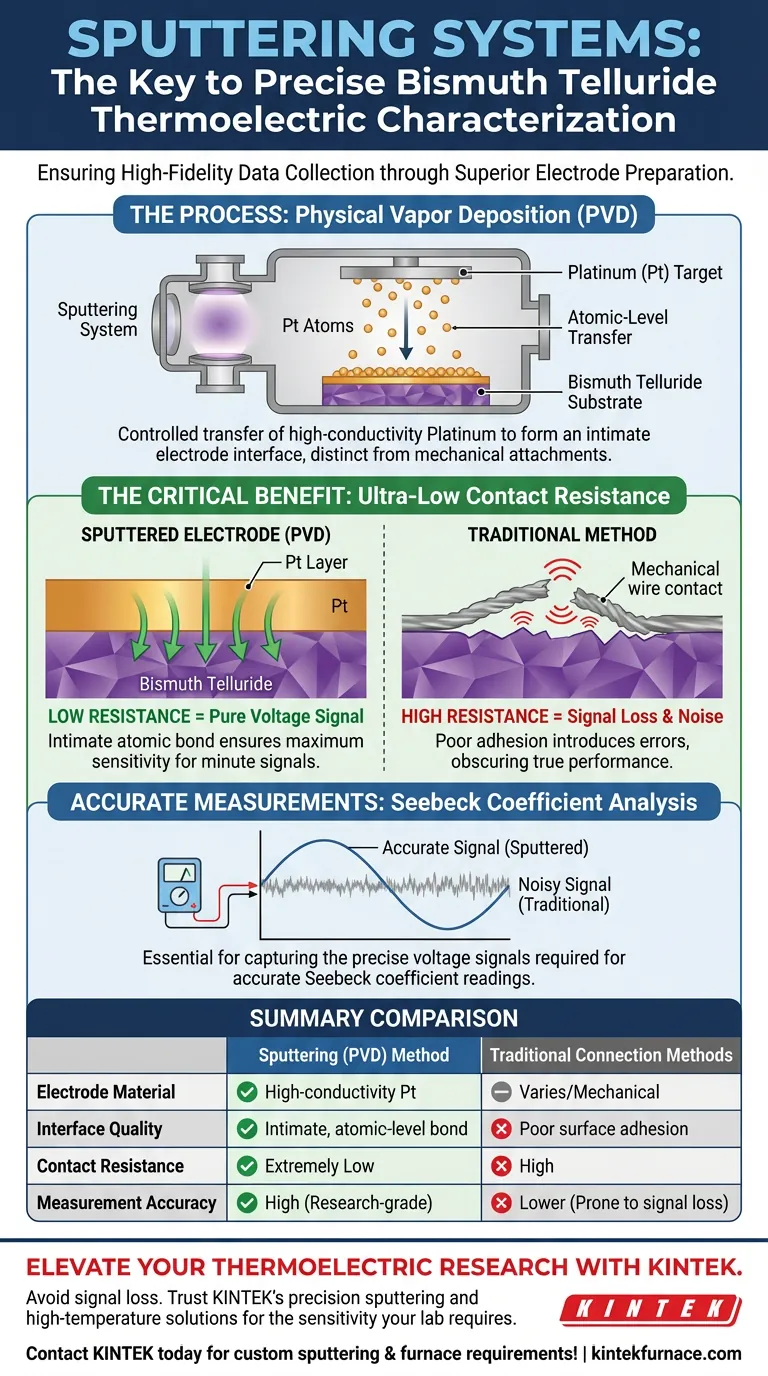

A sputtering system serves as a critical tool for ensuring high-fidelity data collection during the thermoelectric characterization of Bismuth Telluride. By utilizing physical vapor deposition (PVD) technology, the system deposits high-conductivity Platinum (Pt) electrodes directly onto the sample surface. This process creates a superior electrical interface compared to standard connection techniques, which is fundamental for accurate voltage measurements.

By significantly lowering contact resistance through precise Platinum deposition, sputtering systems ensure the sensitivity required to accurately capture voltage signals for Seebeck coefficient analysis.

The Process of Electrode Formation

Physical Vapor Deposition (PVD)

The sputtering system operates on the principle of Physical Vapor Deposition.

This advanced technology allows for the controlled transfer of material from a source to a substrate at the atomic level.

In the context of Bismuth Telluride characterization, this method is used to construct the electrode interface rather than simply attaching wires mechanically.

Platinum (Pt) Deposition

The system specifically deposits Platinum (Pt) onto the Bismuth Telluride samples.

Platinum is selected for its high conductivity and stability.

By coating the sample with this specific metal, the system establishes a highly conductive pathway necessary for subsequent electrical testing.

The Criticality of Low Contact Resistance

Superior Interface Quality

The primary advantage of using a sputtering system is the dramatic reduction in contact resistance.

Electrodes prepared via sputtering form an intimate, low-resistance interface with the Bismuth Telluride surface.

This contrasts sharply with traditional connection methods, which often suffer from higher resistance due to poor surface adhesion or material mismatch.

Ensuring Measurement Sensitivity

Low contact resistance is not merely a structural feature; it directly dictates measurement accuracy.

In thermoelectric characterization, particularly when measuring the Seebeck coefficient, the system must capture minute voltage signals.

A high-resistance interface would introduce noise or voltage drops, obscuring the true performance of the material. Sputtering ensures the voltage signal remains pure and sensitive.

Understanding the Trade-offs

Sputtering vs. Traditional Methods

While sputtering provides superior data, it is important to understand why it is compared against "traditional connection methods."

Traditional methods may be faster or require less equipment, but they compromise the integrity of the electrical contact.

The trade-off for the high accuracy provided by sputtering is the requirement for specialized PVD equipment, but this is a necessary investment for avoiding the signal loss associated with simpler manual connections.

Making the Right Choice for Your Goal

To maximize the quality of your thermoelectric analysis, consider the following recommendations:

- If your primary focus is High-Precision Characterization: Prioritize the use of a sputtering system to deposit Platinum electrodes, as this guarantees the low contact resistance required for accurate Seebeck coefficient readings.

- If your primary focus is Avoiding Signal Loss: Avoid traditional connection methods, which create inferior interfaces that can degrade voltage signal sensitivity.

Using a sputtering system is the definitive method for transforming Bismuth Telluride samples into testable devices with research-grade accuracy.

Summary Table:

| Feature | Sputtering (PVD) Method | Traditional Connection Methods |

|---|---|---|

| Electrode Material | High-conductivity Platinum (Pt) | Varies (Mechanical/Adhesive) |

| Interface Quality | Intimate, atomic-level bond | Poor surface adhesion |

| Contact Resistance | Extremely Low | High |

| Measurement Accuracy | High (Research-grade) | Lower (Prone to signal loss) |

| Primary Benefit | Precise Seebeck coefficient analysis | Lower equipment requirement |

Elevate Your Thermoelectric Research with Precision Sputtering

Precise material characterization starts with a superior electrical interface. At KINTEK, we understand that accurate data collection for Bismuth Telluride depends on high-quality electrode deposition. Backed by expert R&D and manufacturing, we offer a comprehensive range of lab equipment—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your unique research needs.

Don't let high contact resistance compromise your Seebeck coefficient analysis. Trust KINTEK’s high-temperature and vacuum solutions to deliver the sensitivity your lab requires.

Contact KINTEK today to discuss your custom sputtering and furnace requirements!

Visual Guide

References

- N.G. Imam, Abd El‐Hady B. Kashyout. Comprehensive study of nanostructured Bi <sub>2</sub> Te <sub>3</sub> thermoelectric materials – insights from synchrotron radiation XRD, XAFS, and XRF techniques. DOI: 10.1039/d3ra06731a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What are the main types of heat treatment furnaces? Choose the Right Furnace for Your Lab or Industry

- What are the primary process objectives of using an infrared belt furnace? Optimize TOPCon Solar Cell Metallization

- How does a box heater work? A Guide to Efficient Whole-Room Heating

- What is the significance of using a laboratory electric furnace for the quenching and tempering of hull steel? Achieve Precise Microstructure Control

- What are the differences between gravity and mechanical convection in laboratory furnaces? Choose the Right Type for Your Lab

- What is the purpose of the annealing process in OLED preparation? Optimize Film Stability and Device Efficiency

- What role does a vacuum oven play in the post-treatment of nano-hydroxyapatite coatings? Ensure Crack-Free Integrity

- How does a high-precision temperature control system assist in evaluating the thermal management capabilities of phosphor materials? Pinpoint Performance for Solar Cells.