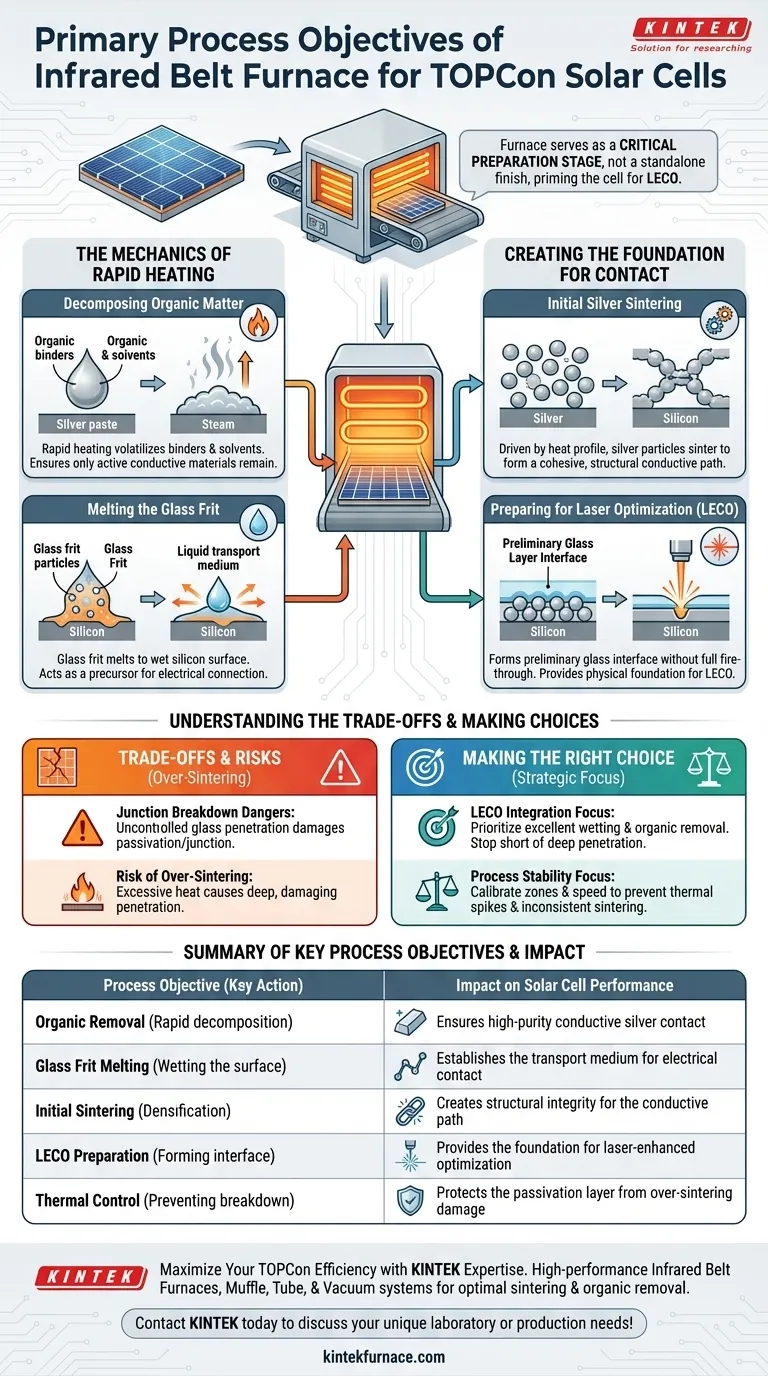

The primary process objectives of using an infrared belt furnace for TOPCon electrode preparation are to rapidly decompose organic components within the silver paste and simultaneously melt the glass frit to wet the silicon surface. This specific thermal treatment is designed to achieve initial sintering of silver particles, creating a preliminary interface that serves as the physical foundation for subsequent contact optimization.

The infrared belt furnace acts as a critical preparation stage rather than a standalone finishing step. It establishes the necessary glass layer interface and silver sintering state required to enable Laser Enhanced Contact Optimization (LECO), ensuring the cell is primed for high-efficiency performance.

The Mechanics of Rapid Heating

Decomposing Organic Matter

The first critical function of the furnace is the removal of non-metallic components.

The silver paste used for metallization contains organic binders and solvents. The furnace uses a rapid heating process to volatilize and decompose this organic matter efficiently. This ensures that only the active conductive materials remain to form the electrode.

Melting the Glass Frit

Simultaneously, the furnace must reach temperatures sufficient to melt the glass frit contained within the paste.

Once molten, this glass frit acts as the transport medium. Its primary role at this stage is to wet the silicon surface effectively. This wetting action is the precursor to establishing an electrical connection between the metal electrode and the silicon wafer.

Creating the Foundation for Contact

Initial Silver Sintering

Beyond cleaning the paste and melting the glass, the furnace drives the initial densification of the metal.

The heat profile causes the silver particles to begin sintering—bonding together to form a cohesive conductive path. This creates the structural integrity required for current transport across the grid fingers.

Preparing for Laser Optimization (LECO)

In modern TOPCon processing, the furnace is often not the final step for contact formation.

The specific objective here is to form a preliminary glass layer interface. By establishing this layer without fully firing through the passivation in a damaging way, the furnace provides the "physical foundation" required for Laser Enhanced Contact Optimization (LECO) technology to subsequently finalize the low-resistance contact.

Understanding the Trade-offs

The Risk of Over-Sintering

While heat is necessary, excessive thermal exposure is a primary failure mode.

If the temperature profile is too aggressive or the conveyor speed is too slow, the process risks "over-sintering." This occurs when the metal paste penetrates too deeply or aggressively into the silicon structure.

Junction Breakdown Dangers

Over-sintering leads directly to junction breakdown.

The supplementary data indicates that if the glass frit penetrates the passivation layer uncontrolled, it can damage the highly doped silicon region or the underlying junction. Therefore, precise control of the temperature profile is essential to balance adequate wetting against the destruction of the cell's voltage-generating capability.

Making the Right Choice for Your Process

Depending on your specific integration strategy, your focus on furnace parameters will shift:

- If your primary focus is LECO integration: Prioritize a profile that achieves excellent glass wetting and organic removal but stops short of deep penetration, leaving the heavy lifting to the laser.

- If your primary focus is process stability: Ensure your conveyor speed and temperature zones are calibrated to prevent thermal spikes that lead to junction damage or inconsistent sintering.

The success of the infrared belt furnace lies in its ability to deliver a precise thermal foundation, balancing material preparation with strict protection of the underlying silicon structure.

Summary Table:

| Process Objective | Key Action | Impact on Solar Cell Performance |

|---|---|---|

| Organic Removal | Rapid decomposition of binders & solvents | Ensures high-purity conductive silver contact |

| Glass Frit Melting | Wetting the silicon surface | Establishes the transport medium for electrical contact |

| Initial Sintering | Densification of silver particles | Creates structural integrity for the conductive path |

| LECO Preparation | Forming preliminary glass interface | Provides the foundation for laser-enhanced optimization |

| Thermal Control | Preventing junction breakdown | Protects the passivation layer from over-sintering damage |

Maximize Your TOPCon Efficiency with KINTEK Expertise

Achieving the perfect thermal profile for TOPCon solar cell metallization requires precision and reliability. Backed by expert R&D and manufacturing, KINTEK offers high-performance Infrared Belt Furnaces, Muffle, Tube, and Vacuum systems designed for the rigorous demands of advanced solar research and production. Our customizable heating solutions ensure optimal sintering and organic removal while protecting delicate junction structures.

Ready to optimize your solar cell contacts? Contact KINTEK today to discuss your unique laboratory or production needs!

Visual Guide

References

- Johannes Greulich, Stefan Rein. Microstructure Analysis of Current‐Fired Contacts on TOPCon Layers. DOI: 10.1002/solr.202500197

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What technical advantages does a custom high-temperature furnace provide for in-situ diffraction on molten sulfur?

- What is the significance of 1200 °C in ZrO2:Ti synthesis? Unlock Phase Purity in High-Performance Ceramics

- How do lab furnaces simulate fire environments for UHPFRC testing? Achieving ISO834 Standard Compliance

- How is a laboratory oven utilized during the impregnation stage of APC preparation? Optimize Biochar Activation

- Why are high-precision constant temperature baths necessary? Unlock Accurate Fiber Optic Sensor Calibration

- How does the "Flux Melting" process in MOF glass preparation utilize heating equipment? Low-Temp MOF Vitrification

- What key data does a Simultaneous Thermal Analyzer (STA) provide for lignite combustion? Assess Fire Risk with Precision

- What is the impact of using a vacuum drying oven on CDI electrodes? Optimize Stability and Conductivity