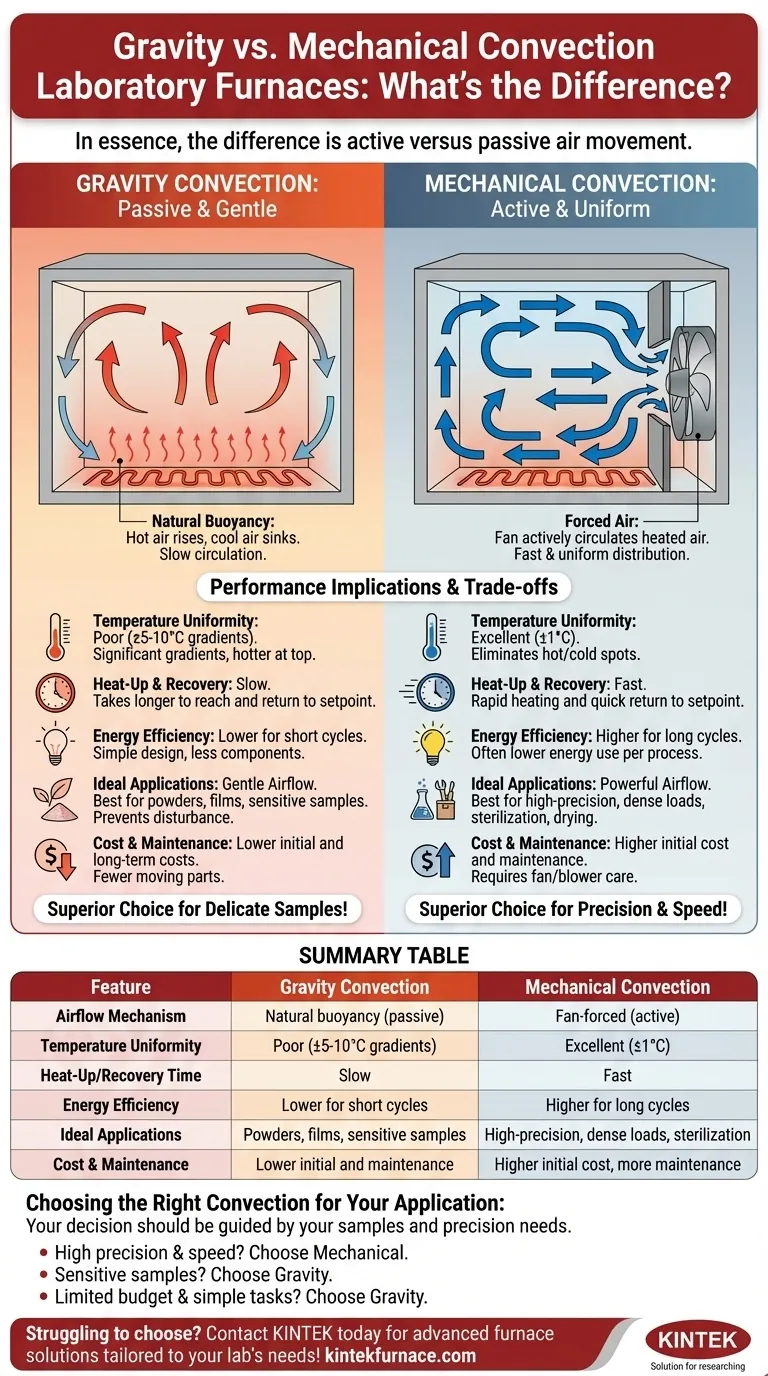

In essence, the difference is active versus passive air movement. A gravity convection furnace relies on the natural principle that hot air rises and cool air sinks, creating a slow, gentle circulation. In contrast, a mechanical convection furnace uses a fan to actively force heated air throughout the chamber, ensuring a much faster and more uniform temperature distribution.

The choice between gravity and mechanical convection is a fundamental trade-off. You are balancing the superior temperature uniformity and speed of mechanical convection against the gentle airflow and simplicity of gravity convection.

The Core Mechanism: How Each Furnace Works

To select the right tool, you must first understand how each one operates. The method of heat circulation directly impacts performance, efficiency, and the types of applications for which each furnace is suited.

Gravity Convection: The Principle of Natural Buoyancy

A gravity convection furnace operates on a simple, passive principle. Heating elements, typically located at the bottom of the chamber, warm the adjacent air.

As this air heats up, it becomes less dense and rises. Upon reaching the top of the chamber, it cools, becomes denser, and sinks back to the bottom to be reheated, creating a slow, continuous circulation loop.

Mechanical Convection: Forcing Uniformity

A mechanical convection furnace takes an active approach. It incorporates a fan or blower, often paired with internal walls called baffles.

The fan forces air across the heating elements and then circulates it throughout the entire chamber at a high velocity. This process eliminates the hot and cold spots inherent in gravity ovens, creating a highly uniform and stable thermal environment.

Performance Implications for Your Lab

The difference in airflow mechanism leads to significant and predictable differences in performance. These factors are critical for the repeatability and accuracy of your work.

Temperature Uniformity

This is the most significant performance difference. A mechanical convection oven provides vastly superior temperature uniformity, often within ±1°C of the setpoint throughout the chamber.

A gravity convection oven will have significant temperature gradients, with the top of the chamber being much hotter than the bottom. This lack of uniformity can compromise results for sensitive applications.

Heat-Up and Recovery Time

Because it actively moves large volumes of air, a mechanical convection furnace heats up to the target temperature much faster.

It also has a significantly shorter recovery time—the time it takes to return to the setpoint temperature after the door has been opened and closed. This leads to higher throughput and more efficient workflows.

Energy Efficiency

While a gravity oven has fewer components and consumes less power at a steady state, its long heat-up times often lead to higher overall energy consumption for a given task.

The speed and efficiency of a mechanical oven mean it reaches its setpoint and completes its cycle more quickly, often resulting in lower energy use per process.

Understanding the Trade-offs

Choosing a furnace is not simply about picking the one with the highest performance. Critical trade-offs exist that may make the simpler option the correct one for specific needs.

The Airflow Dilemma: Powders and Films

The powerful airflow in a mechanical convection oven can be a significant disadvantage for certain samples. It can easily disturb or blow away lightweight powders, soils, or delicate films.

For these applications, the gentle, low-velocity airflow of a gravity convection oven is often the superior choice, as it heats the sample without disturbing it.

Simplicity, Cost, and Maintenance

Gravity convection ovens have a simpler design with no fans, motors, or complex baffling. This makes them less expensive to purchase and reduces the number of components that could potentially fail.

Their simplicity translates to lower long-term maintenance costs, a key consideration for budget-conscious labs.

Chamber Size and Load Density

Mechanical convection is almost a necessity for large-capacity ovens or when processing densely packed sample loads.

Natural gravity circulation lacks the power to effectively penetrate a crowded chamber and heat all samples evenly. The forced air of a mechanical oven ensures that every item, regardless of its position, receives uniform heating.

Choosing the Right Convection for Your Application

Your decision should be guided by the specific demands of your samples and the required precision of your results.

- If your primary focus is high precision, temperature uniformity, and fast processing: Choose a mechanical convection furnace for applications like analytical testing, materials curing, and sterilization.

- If your primary focus is drying lightweight powders, films, or samples sensitive to airflow: The gentle heating of a gravity convection furnace is the correct choice to protect sample integrity.

- If your primary focus is a limited budget for simple heating tasks where strict uniformity is not critical: A gravity convection furnace provides a reliable and cost-effective solution.

Ultimately, understanding how each technology moves air allows you to match the right tool to your specific scientific or industrial goal.

Summary Table:

| Feature | Gravity Convection | Mechanical Convection |

|---|---|---|

| Airflow Mechanism | Natural buoyancy (passive) | Fan-forced (active) |

| Temperature Uniformity | Poor (±5-10°C gradients) | Excellent (±1°C) |

| Heat-Up/Recovery Time | Slow | Fast |

| Energy Efficiency | Lower for short cycles | Higher for long cycles |

| Ideal Applications | Powders, films, sensitive samples | High-precision, dense loads, sterilization |

| Cost & Maintenance | Lower initial and maintenance costs | Higher initial cost, more maintenance |

Struggling to choose the right furnace for your lab's unique needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your experimental requirements. Whether you need gentle heating for sensitive samples or fast, uniform processing for high-precision tasks, we can help. Contact us today to discuss how our furnaces can enhance your lab's efficiency and accuracy!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why does the use of a forced-air drying oven often lead to increased particle size? Avoid Silica Agglomeration

- What is the use of furnace in laboratory? Unlock Precise High-Temperature Control for Material Transformations

- What mechanisms generate heat in induction heating? Discover the Science of Efficient Material Processing

- What is the significance of an in-situ high-temperature heating stage? Unlock Real-Time Crystal Structure Insights

- Why is a secondary calcination furnace required after ball milling? Unlock High-Purity Hydroxyapatite Synthesis

- What is the primary purpose of using a vacuum drying oven at 100°C? Optimize Aluminum Foil Coating Performance

- Why is a furnace with high-precision temperature control required for DPKB-S? Ensuring Material Synthesis Accuracy

- Why must the steam-to-carbon (S/C) ratio be strictly controlled? Protect Your Reforming Catalyst and Process