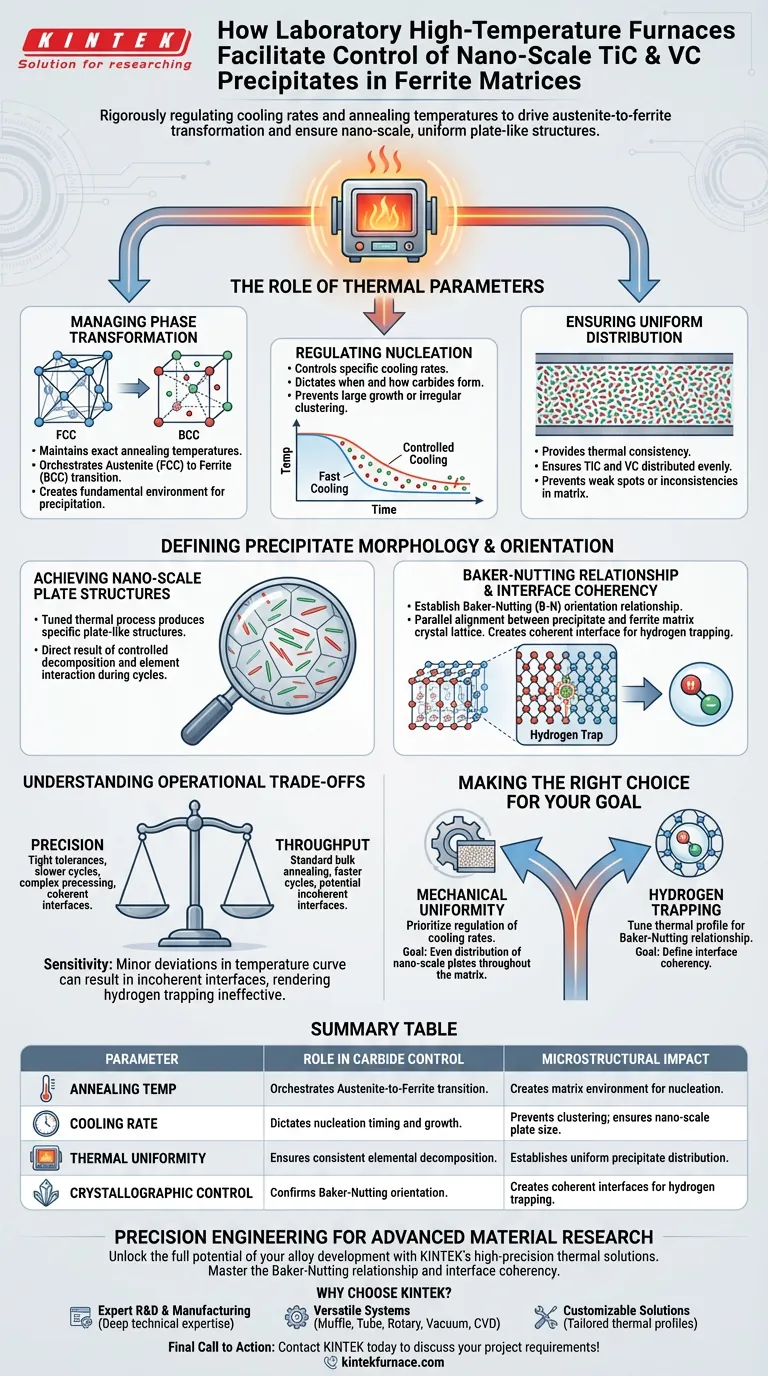

Laboratory high-temperature furnaces facilitate the control of Titanium Carbide (TiC) and Vanadium Carbide (VC) precipitates by rigorously regulating cooling rates and annealing temperatures. This precise thermal management drives the transformation of the metal matrix from austenite to ferrite, ensuring the carbides nucleate as uniform, nano-scale plate-like structures.

The core function of these furnaces is to establish the specific thermal conditions required to confirm the Baker-Nutting orientation relationship. This crystallographic alignment is the physical basis for defining interface coherency and enabling advanced mechanisms like hydrogen trapping.

The Role of Thermal Parameters

Managing Phase Transformation

The furnace must maintain exact annealing temperatures to orchestrate the transition of the matrix from austenite to ferrite. This phase change creates the fundamental environment necessary for the subsequent precipitation of carbides.

Regulating Nucleation

By controlling the specific cooling rates, the furnace dictates exactly when and how the carbides begin to form (nucleate). This prevents the carbides from growing too large or clustering irregularly.

Ensuring Uniform Distribution

The thermal consistency provided by high-quality furnaces ensures that TiC and VC precipitates are distributed evenly throughout the material. This prevents weak spots or inconsistencies within the ferrite matrix.

Defining Precipitate Morphology and Orientation

Achieving Nano-Scale Plate Structures

The thermal process is tuned to produce precipitates that are not only nano-scale but specifically shaped as plate-like structures. This morphology is a direct result of the controlled decomposition and interaction of elements during the heating and cooling cycles.

The Baker-Nutting Relationship

The ultimate goal of this thermal control is to achieve the Baker-Nutting orientation relationship. This describes a specific parallel alignment between the crystal lattice of the precipitate and the ferrite matrix.

Interface Coherency

When the Baker-Nutting relationship is successfully established via thermal processing, the interface between the precipitate and the matrix becomes coherent. This coherency is critical for the material's ability to act as a hydrogen trap.

Understanding the Operational Trade-offs

Precision vs. Throughput

Achieving the exact Baker-Nutting orientation requires extremely tight tolerances on thermal profiles. Prioritizing this level of microstructural precision often requires slower, more complex processing cycles compared to standard bulk annealing.

The Sensitivity of Interface Coherency

The mechanism of hydrogen trapping relies entirely on the interface coherency established during heating. Even minor deviations in the temperature curve can result in incoherent interfaces, rendering the hydrogen trapping mechanism ineffective.

Making the Right Choice for Your Goal

To leverage high-temperature furnaces effectively for TiC and VC precipitation, align your process parameters with your specific material objectives:

- If your primary focus is mechanical uniformity: Prioritize the regulation of cooling rates to ensure the nano-scale plate-like structures are distributed evenly throughout the ferrite matrix.

- If your primary focus is hydrogen trapping: Ensure your thermal profile is specifically tuned to reach the conditions necessary to confirm the Baker-Nutting orientation relationship, as this defines the interface coherency.

Precise thermal management is not merely about heating a material; it is about engineering the atomic interface between the precipitate and the matrix.

Summary Table:

| Parameter | Role in Carbide Control | Microstructural Impact |

|---|---|---|

| Annealing Temp | Orchestrates Austenite-to-Ferrite transition | Creates the matrix environment for nucleation |

| Cooling Rate | Dictates nucleation timing and growth | Prevents clustering; ensures nano-scale plate size |

| Thermal Uniformity | Ensures consistent elemental decomposition | Establishes uniform precipitate distribution |

| Crystallographic Control | Confirms Baker-Nutting orientation | Creates coherent interfaces for hydrogen trapping |

Precision Engineering for Advanced Material Research

Unlock the full potential of your alloy development with KINTEK’s high-precision thermal solutions. Whether you are engineering hydrogen traps or optimizing mechanical uniformity, our laboratory high-temperature furnaces provide the rigorous thermal regulation necessary to master the Baker-Nutting orientation relationship and interface coherency.

Why choose KINTEK for your research?

- Expert R&D & Manufacturing: Backed by deep technical expertise in material science.

- Versatile Systems: From Muffle and Tube furnaces to Rotary, Vacuum, and CVD systems.

- Customizable Solutions: Tailored thermal profiles to meet your unique nano-scale precipitation needs.

Contact KINTEK today to discuss your project requirements!

Visual Guide

References

- Tim Boot, Vera Popovich. Hydrogen trapping and embrittlement of titanium- and vanadium carbide-containing steels after high-temperature hydrogen charging. DOI: 10.1007/s10853-024-09611-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of solution and aging heat treatment furnaces? Optimize 17-4 PH Stainless Steel Properties

- What are the main advantages of crucible furnaces? Unmatched Flexibility for Small-Scale Melting

- What critical environmental conditions does a high-temperature recrystallization annealing furnace provide? Maximize Steel Strength

- What are the key considerations when choosing a continuous furnace? Optimize Your High-Volume Production

- What is the importance of a laboratory oven's programmed heating for epoxy-polyimide curing? Essential Thermal Control

- Why is a N2 and SF6 gas protection system required for magnesium melting? Ensure Safety and Alloy Purity

- How does a constant temperature and humidity curing chamber contribute to GCCM hydration? Optimize Material Strength

- Why is industrial-grade isostatic pressing necessary for zirconia? Achieve Uniform Density & Structural Integrity