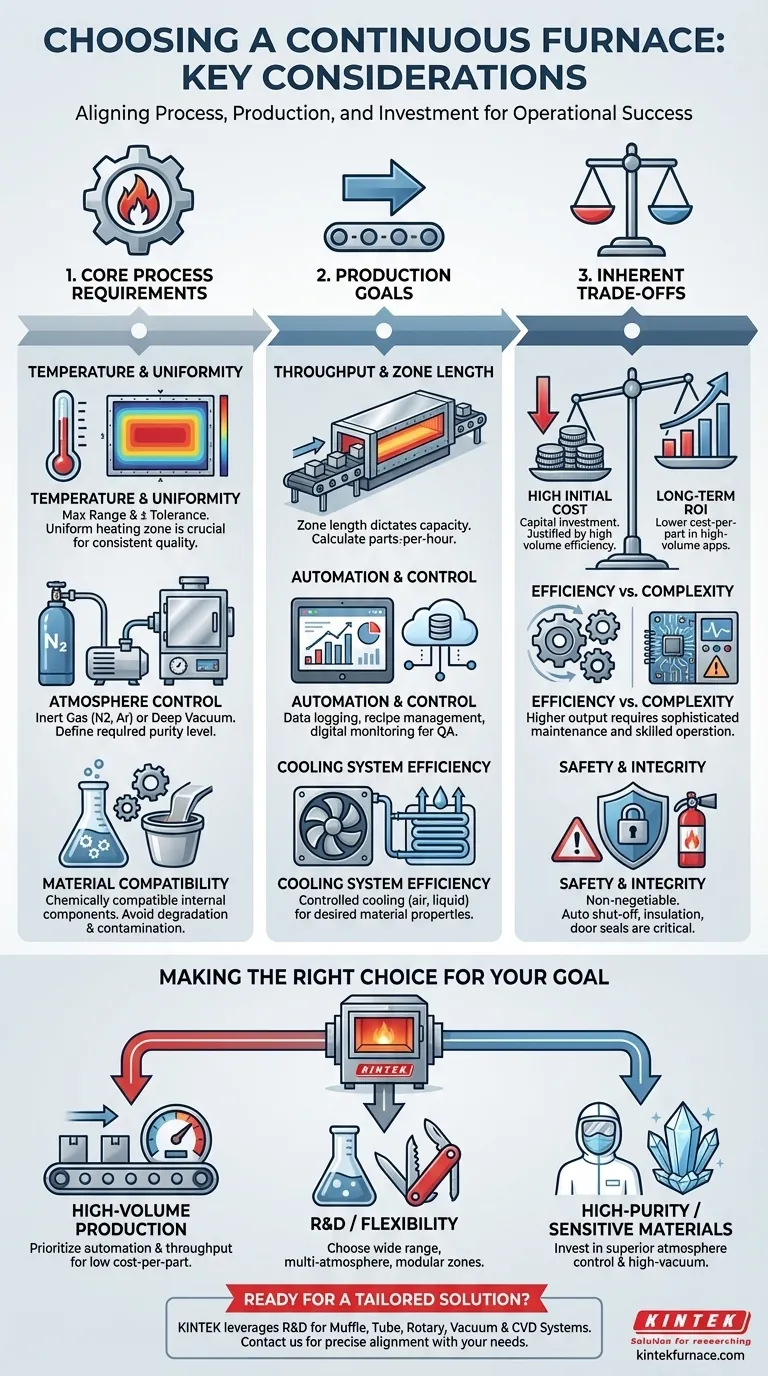

When selecting a continuous furnace, your decision must be driven by three core factors: the specific thermal and atmospheric requirements of your process, the required production volume and speed, and the total cost of ownership beyond the initial purchase. A continuous furnace is a significant capital investment, and its specifications must align perfectly with your operational goals to ensure efficiency, quality, and a positive return.

Choosing a continuous furnace is not about buying a piece of equipment; it's about designing a critical part of your production system. The best choice moves beyond just hitting a target temperature and instead focuses on ensuring process repeatability, throughput, and long-term operational reliability.

Defining Your Core Process Requirements

The furnace's primary function is to create a specific, controlled environment. Your first step is to precisely define what that environment looks like for your application.

Maximum Temperature and Uniformity

The most fundamental specification is the temperature range. You must select a furnace that can not only reach your required maximum temperature but also maintain it with exceptional uniformity across the entire heating zone.

Poor temperature uniformity leads to inconsistent product quality. Always look for specifications on temperature tolerance (e.g., ±5°C) and ensure the furnace has over-temperature protection to prevent damage to the equipment and your product.

Atmosphere Control

Many modern processes require a controlled atmosphere to prevent oxidation or facilitate specific chemical reactions. This can range from flowing an inert gas like nitrogen or argon to operating under a deep vacuum.

Your choice here is critical. Define the level of purity required, as this will dictate the need for features like high-purity gas lines, advanced vacuum pumps, and sophisticated monitoring systems to ensure atmospheric integrity.

Material and Component Compatibility

The materials used to construct the furnace's chamber or tube must be chemically compatible with your process materials and gases, especially at high temperatures.

An incompatible material can degrade, contaminate your product, and lead to premature equipment failure. Consider factors like chemical resistance and thermal shock resistance when evaluating the furnace's internal components.

Aligning the Furnace with Production Goals

A continuous furnace is a machine for production. Its physical design and control systems must be sized and configured to meet your specific throughput and quality assurance targets.

Throughput and Heating Zone Length

The production capacity is directly tied to the length of the heating zone and the speed of the conveying system. A longer heating zone allows for a faster throughput while ensuring each part spends the required amount of time at temperature.

Calculate your required parts-per-hour and work backward to determine the necessary heating zone length and conveyor speed. This prevents a bottleneck in your production line.

Automation and Process Control

Modern manufacturing demands data. A furnace with robust automation and process control allows for digital monitoring, recipe management, and data logging for quality assurance.

This ensures every part is processed under the exact same conditions, providing the repeatability essential for certification and quality control. Look for systems that can be integrated into your plant-wide network.

Cooling System Efficiency

The cooling phase is just as critical as the heating phase for achieving the desired material properties, such as hardness or crystal structure.

An efficient and controlled cooling system ensures consistent and predictable results. Evaluate whether you need simple air cooling, forced convection, or a liquid-cooled jacket to manage the cooling profile accurately.

Understanding the Inherent Trade-offs

Choosing a continuous furnace involves balancing competing priorities. Understanding these trade-offs is key to making an objective, informed decision.

High Initial Cost vs. Long-Term ROI

Continuous furnaces have a significantly higher initial cost compared to batch furnaces. This investment is justified by their high production efficiency and lower cost-per-part in high-volume applications.

However, if your production volume is low or inconsistent, the high capital and maintenance costs may not deliver a positive return on investment (ROI).

Production Efficiency vs. Operational Complexity

The efficiency of a continuous furnace comes with increased complexity. These systems require more sophisticated maintenance schedules and more highly skilled operators than simpler batch systems.

Factor the cost of training, maintenance personnel, and spare parts into your total cost of ownership calculation.

Safety and System Integrity

Robust safety features are non-negotiable. Elements like automatic shut-off mechanisms, high-quality insulation, and effective door seals are critical for protecting personnel and ensuring thermal efficiency.

Never compromise on safety. A failure in these systems can lead to equipment damage, ruined product, and, most importantly, a hazardous work environment.

Making the Right Choice for Your Goal

Your final decision should be guided by your single most important operational driver.

- If your primary focus is high-volume, standardized production: Prioritize automation, throughput speed, and a design optimized for low long-term cost-per-part.

- If your primary focus is research, development, or process flexibility: Choose a furnace with a wide operating range, multiple atmosphere capabilities, and modular heating zones.

- If your primary focus is processing high-purity or sensitive materials: Invest in superior atmosphere control, high-vacuum capabilities, and verified material compatibility.

Making the right choice is an exercise in aligning the technical specifications of the furnace with the strategic goals of your operation.

Summary Table:

| Consideration | Key Points |

|---|---|

| Process Requirements | Temperature range, uniformity, atmosphere control, material compatibility |

| Production Goals | Throughput, automation, cooling efficiency |

| Trade-offs | Cost vs. ROI, efficiency vs. complexity, safety features |

Ready to enhance your production with a tailored continuous furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique needs for improved efficiency and reliability. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency