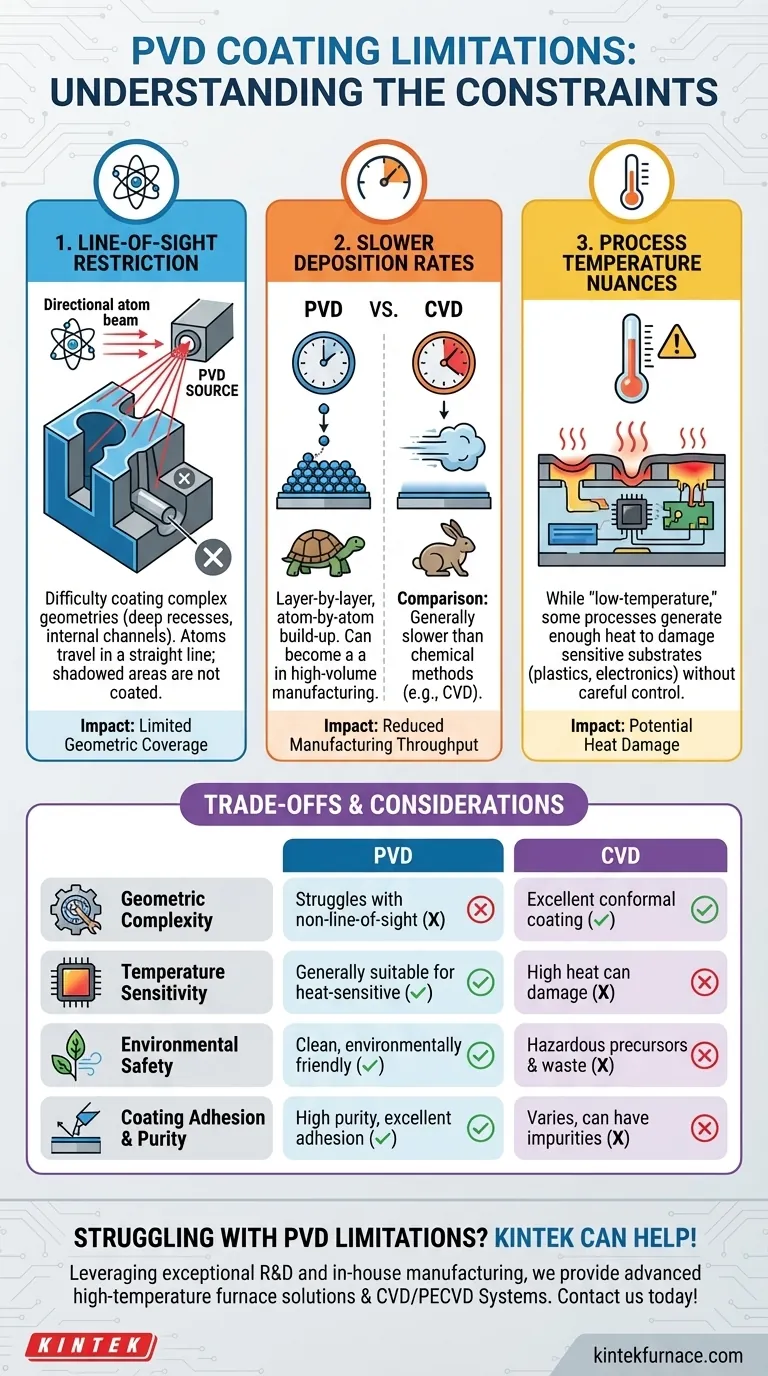

While a powerful and versatile surface engineering method, Physical Vapor Deposition (PVD) is not a universal solution. Its principal limitations are its reliance on a direct line of sight between the coating source and the target surface, making it difficult to coat complex geometries, and its generally slower deposition rates compared to other methods, which can impact manufacturing throughput. Additionally, while PVD is a low-temperature process, some sensitive substrates can still be affected without careful process control.

The core limitations of PVD are not flaws in the technology, but inherent consequences of its physical, line-of-sight mechanism. Understanding this allows you to select PVD for applications where its precision is a strength and avoid it where geometric complexity or speed are the primary concerns.

The Core Limitations of PVD Explained

To effectively leverage PVD, you must understand the "why" behind its constraints. These limitations stem directly from the physics of the process itself.

The "Line-of-Sight" Restriction

PVD works by bombarding a solid material (the "target") with ions, causing atoms to be ejected and travel in a straight line through a vacuum to deposit onto the substrate.

This means if a surface is not in the direct path of these traveling atoms, it will not be coated. This is a significant constraint for parts with deep recesses, internal channels, or complex three-dimensional shapes.

Slower Deposition Rates

The PVD process builds up the coating layer by layer, atom by atom. This physical deposition is inherently more controlled but also slower than chemical processes.

Compared to an alternative like Chemical Vapor Deposition (CVD), PVD's lower deposition rate can become a bottleneck in high-volume manufacturing, potentially increasing cycle time and cost per part.

The Nuance of Process Temperature

PVD is rightly known as a "low-temperature" process, especially when compared to the very high heat required for CVD. This makes it ideal for many heat-sensitive materials.

However, "low temperature" is relative. Some PVD processes can still generate enough heat to damage extremely sensitive substrates, such as certain plastics or electronic components. Careful management and control of process parameters are essential to mitigate this risk.

Understanding the Trade-offs: PVD vs. Alternatives

No coating technology exists in a vacuum. Choosing the right one means weighing its limitations against its benefits and comparing it to other options like Chemical Vapor Deposition (CVD).

Geometric Complexity and Coverage

PVD struggles with non-line-of-sight surfaces. In contrast, CVD uses a precursor gas that can flow into and around complex features, resulting in a highly uniform (or "conformal") coating on all exposed surfaces, including internal ones.

Substrate and Temperature Sensitivity

This is a major trade-off. PVD's lower operating temperatures make it suitable for a wide range of materials, including hardened steels, alloys, and some polymers that would be damaged by CVD's high heat.

Environmental and Safety Impact

PVD is a clean, environmentally friendly process that produces minimal toxic by-products. CVD, on the other hand, often involves volatile and hazardous chemical precursors and can produce toxic waste that requires stringent and costly safety and disposal protocols.

Coating Adhesion and Purity

PVD coatings are known for their high purity and excellent adhesion to the substrate. The process occurs in a high vacuum, which minimizes the inclusion of contaminants and results in a very strong, dense coating.

Making the Right Choice for Your Application

Your final decision must be driven by your project's most critical requirements. Use these limitations as a guide to select the right tool for the job.

- If your primary focus is coating complex internal geometries: Consider alternatives like Chemical Vapor Deposition (CVD), as PVD's line-of-sight nature is a significant barrier.

- If your primary focus is high-volume, rapid production: You must weigh PVD's slower deposition rates against the higher operational complexity and environmental concerns of faster methods.

- If your primary focus is coating heat-sensitive materials: PVD is generally the superior choice, but ensure process parameters are tightly controlled for highly sensitive substrates.

- If your primary focus is environmental safety and coating purity: PVD offers a distinct advantage with minimal toxic by-products and exceptionally high-purity results.

Understanding these fundamental limitations allows you to leverage PVD's strengths precisely where they deliver the most value.

Summary Table:

| Limitation | Key Impact |

|---|---|

| Line-of-Sight Restriction | Difficulty coating complex geometries, such as deep recesses or internal channels |

| Slower Deposition Rates | Reduced manufacturing throughput compared to methods like CVD |

| Process Temperature Nuances | Potential heat damage to sensitive substrates without careful control |

Struggling with PVD coating limitations? KINTEK can help! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, whether you're dealing with complex geometries, high-volume production, or sensitive materials. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temp, High-Quality Film Deposition

- Is PECVD directional? Understanding Its Non-Line-of-Sight Advantage for Complex Coatings

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings