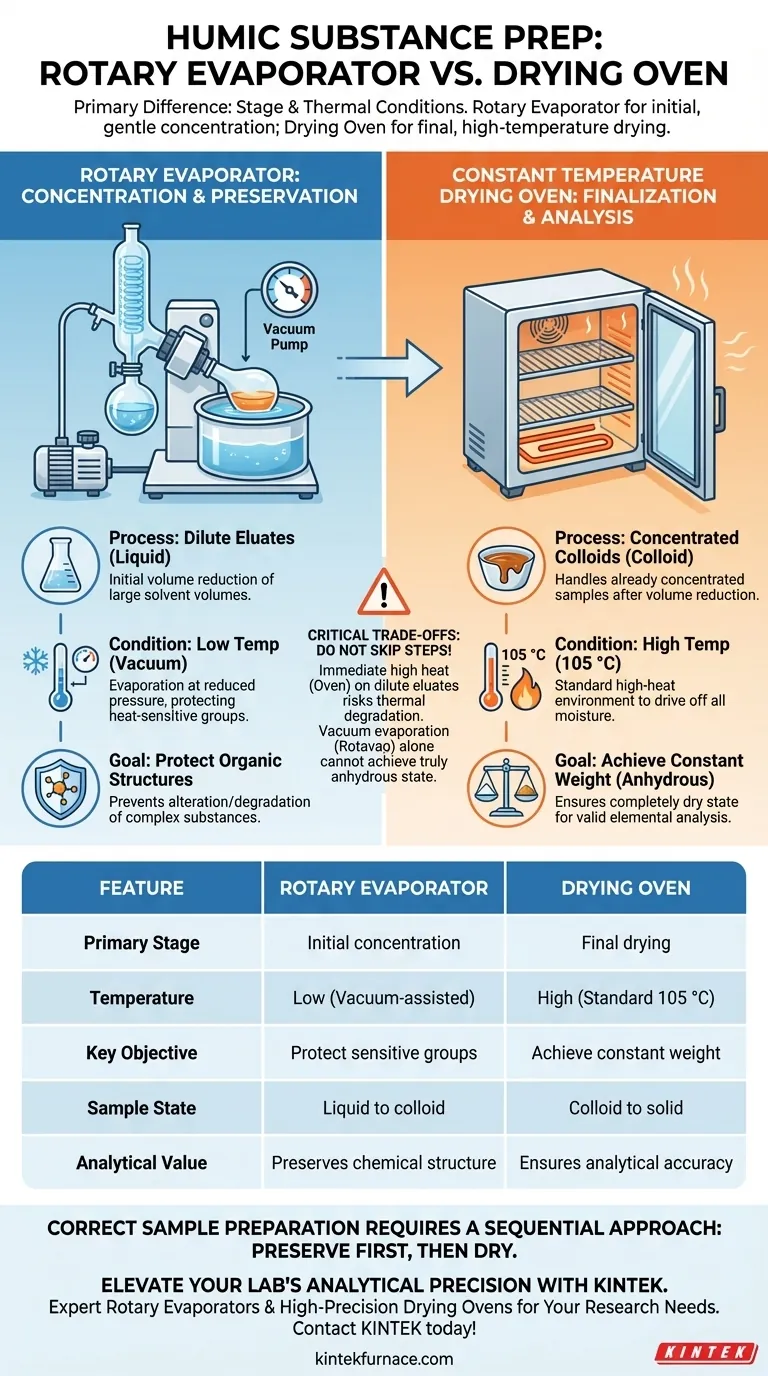

The primary difference lies in the stage of preparation and the thermal conditions applied. A rotary evaporator is used for the initial, gentle concentration of dilute liquids under vacuum to preserve chemical structure, while a constant temperature drying oven is used for the final, high-temperature drying of solids to ensure they are completely moisture-free.

While the rotary evaporator reduces volume while protecting heat-sensitive organic components, the drying oven ensures the sample reaches a completely anhydrous state required for accurate elemental and spectroscopic analysis.

The Role of the Rotary Evaporator: Concentration and Preservation

Processing Dilute Eluates

The rotary evaporator is specifically utilized for the concentration of dilute fulvic acid eluates.

This step is typically the intermediate phase where large volumes of solvent are removed to create a more manageable concentrate.

Low-Temperature Operation

The critical feature of this device is its ability to operate under vacuum.

This allows for evaporation at significantly lower temperatures, which is essential for sample preservation.

Protecting Functional Groups

The primary goal here is protecting heat-sensitive organic functional groups.

By avoiding high heat during the bulk reduction of liquid, you prevent the structural alteration or degradation of the complex humic substances.

The Role of the Drying Oven: Finalization and Analysis

Processing Concentrated Colloids

The constant temperature drying oven is employed after the initial concentration, specifically for concentrated humic and fulvic acid colloids.

It handles samples that have already undergone volume reduction.

High-Temperature Drying

This equipment operates at a standard temperature of 105 °C.

Unlike the rotary evaporator, this is a high-heat environment designed to drive off all remaining water.

Achieving Constant Weight

The objective is to dry the colloids until they reach a constant weight.

This ensures the samples are in a verifiable anhydrous solid state, which is a strict requirement for valid elemental analysis and spectroscopic testing.

Understanding the Critical Trade-offs

The Risk of Thermal Degradation

You cannot skip the rotary evaporator step and place dilute samples directly into an oven.

Subjecting dilute eluates immediately to 105 °C would likely destroy the delicate organic structures you intend to analyze before you even obtain a solid sample.

The Limitation of Vacuum Evaporation

Conversely, a rotary evaporator generally cannot achieve a truly anhydrous state.

It serves to concentrate the sample safely, but it lacks the thermal energy required to remove the final traces of bound moisture necessary for accurate weight-based analysis.

Making the Right Choice for Your Goal

To ensure the integrity of your humic substance analysis, you must apply each tool at the correct stage of the workflow.

- If your primary focus is preserving sample chemistry: Rely on the rotary evaporator to remove the bulk of your solvent, as its vacuum capabilities protect sensitive organic groups from heat damage.

- If your primary focus is analytical accuracy: You must finish the process with a constant temperature drying oven at 105 °C to ensure the sample is completely dry (anhydrous) for valid spectroscopic or elemental results.

Correct sample preparation requires a sequential approach: preserve the structure first, then rigorously dry the final solid.

Summary Table:

| Feature | Rotary Evaporator | Constant Temperature Drying Oven |

|---|---|---|

| Primary Stage | Initial concentration of dilute eluates | Final drying of concentrated colloids |

| Temperature | Low (Vacuum-assisted evaporation) | High (Standard 105 °C) |

| Key Objective | Protect heat-sensitive functional groups | Achieve constant weight (anhydrous state) |

| Sample State | Liquid to concentrated colloid | Colloid to solid powder |

| Analytical Value | Preserves chemical structure | Ensures accuracy for elemental analysis |

Elevate Your Lab's Analytical Precision with KINTEK

High-quality sample preparation is the foundation of reliable research. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab solutions, including Rotary Evaporators for gentle concentration and high-precision Drying Ovens, all customizable to meet your unique humic substance research needs.

Whether you are processing heat-sensitive organic compounds or requiring rigorous anhydrous results for spectroscopic analysis, our team is ready to provide the specialized equipment your workflow demands.

Contact KINTEK today to find the perfect thermal solution for your laboratory!

Visual Guide

References

- Isolation of Humic Substances Using Waste Wood Ash Extracts: Multiparametric Optimization via Box–Behnken Design and Chemical Characterization of Products. DOI: 10.3390/molecules30153067

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is an electric heating furnace integrated with a capsule-piercing reactor? Ensure Precise Fluid Analysis

- Why is programmable heating equipment necessary for composite curing? Master Thermal Control for Superior Strength

- How do precision temperature-controlled ovens function for SiC-Ti3SiC2 preform curing? Expert Thermal Control Guide

- How does substrate preheating equipment affect the formation and distribution of the Laves phase in Inconel 718?

- How does CFD simulation software optimize fuel combustion? Transform Furnace Efficiency with Digital Twins

- What is the purpose of the long-term stabilization sintering step at 250°C? Secure Your CuO Nano-Network Integrity

- How is a laboratory heat treatment furnace used for fluoride nanocrystal crystallization? Optimize Microstructure Control

- What technical advantages does Joule heating equipment offer? Achieving High-Efficiency Single-Atom Catalyst Synthesis