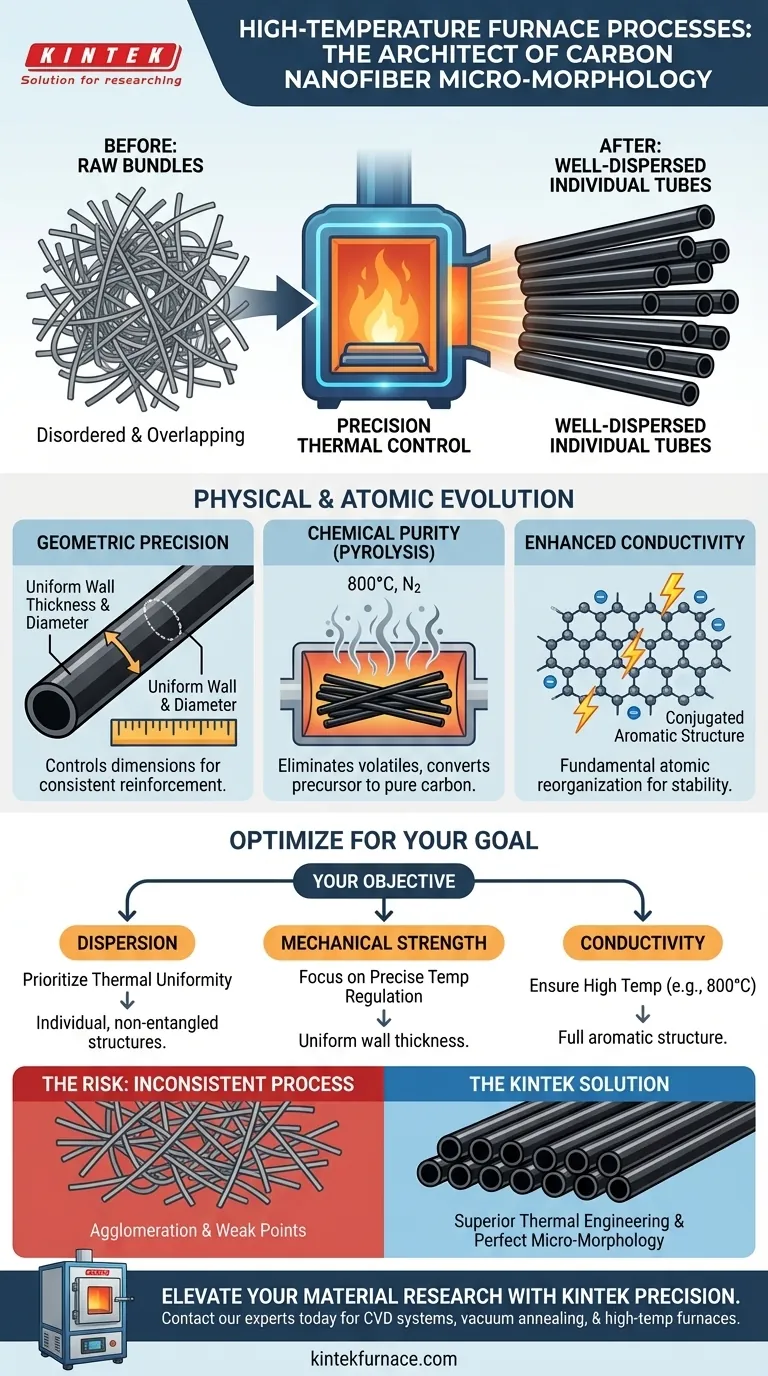

High-temperature furnace processes act as the primary architect of carbon nanofiber (CNF) micro-morphology. They govern the physical transition from disordered, overlapping bundles into well-dispersed, individual tubular structures while defining critical geometric parameters like wall thickness and diameter.

Core Takeaway Precision thermal control in systems like CVD or vacuum annealing is not just about heating; it is about refining the fiber's architecture. It converts raw precursors into stable, conductive fibers with specific dimensions optimized for composite reinforcement.

The Transformation of Physical Structure

Breaking the Bundles

Raw or precursor fibers often exist as overlapping, entangled bundles.

The high-temperature environment is the mechanism that separates these aggregates.

Proper thermal treatment ensures the material transitions into well-dispersed, individual structures, which is a prerequisite for accurate structural analysis and effective material performance.

Defining Geometric Parameters

The furnace environment directly dictates the fiber's physical dimensions.

Specifically, the thermal profile controls the wall thickness and diameter of the resulting nanofibers.

Consistency in these parameters is critical, as they determine how well the fibers function as fillers in composite materials.

Establishing Distinct Features

Beyond size, heat determines shape.

Controlled annealing helps resolve the internal architecture, ensuring the formation of distinct tubular features.

This clarity in structure distinguishes high-quality nanofibers from amorphous carbon deposits.

Chemical and Atomic Evolution

Pyrolysis and Volatile Removal

In specific applications like cellulose-based CNF preparation, the furnace facilitates pyrolysis.

Operating at temperatures such as 800 °C under a protective nitrogen atmosphere, the furnace eliminates volatile components.

This purification process is essential for converting the raw precursor into pure carbon.

Enhancing Stability and Conductivity

The high thermal energy drives a fundamental atomic reorganization.

It transforms the material into a conjugated aromatic structure.

This structural shift significantly enhances the electrical conductivity and overall structural stability of the nanofibers.

Understanding the Trade-offs

The Risk of Thermal Instability

The primary reference emphasizes the need for "proper thermal control."

If the temperature profile fluctuates or is uneven, the transition from bundled to individual fibers may be incomplete.

This results in agglomerations that are difficult to disperse and analyze.

Dimensional Inconsistency

Furnace conditions that are not strictly regulated lead to variable wall thicknesses.

Inconsistent dimensions create weak points in the fiber.

When used as fillers, these irregularities compromise the mechanical integrity of the final composite material.

Making the Right Choice for Your Goal

To optimize your carbon nanofibers, you must align your furnace parameters with your specific performance objectives.

- If your primary focus is Dispersion: Prioritize thermal uniformity to ensure the complete transition from overlapping bundles to discrete, individual fibers.

- If your primary focus is Mechanical Strength: Focus on precise temperature regulation to dictate uniform wall thickness and diameter, ensuring consistent reinforcement capabilities.

- If your primary focus is Conductivity: Ensure high processing temperatures (e.g., 800 °C) to drive the full formation of conjugated aromatic structures.

Ultimately, the furnace is not merely a heat source, but a precision tool that defines the physical identity and utility of the nanofiber.

Summary Table:

| Process Objective | Thermal Impact | Morphological Result |

|---|---|---|

| Dispersion | Bundle Separation | Individual, non-entangled tubular structures |

| Geometric Precision | Controlled Thermal Profile | Uniform wall thickness and fiber diameter |

| Chemical Purity | Pyrolysis (e.g., 800°C in N2) | Removal of volatiles and amorphous carbon |

| Conductivity | Atomic Reorganization | Formation of conjugated aromatic structures |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your carbon nanofibers through superior thermal engineering. KINTEK provides industry-leading CVD systems, vacuum annealing furnaces, and high-temp tube furnaces specifically designed to provide the precision thermal control required for perfect micro-morphology and conductivity.

Whether you are scaling production or refining material architecture, our expert R&D and customizable manufacturing solutions ensure your fibers meet exact specifications. Empower your lab with KINTEK—Contact our experts today to discuss your unique project needs!

Visual Guide

References

- Teguh Endah Saraswati, Wijang Wisnu Raharjo. Enhanced Performance of Epoxy Resin-Polyimide Hybrid Composites with Aminated Carbon Nanofibers Filler. DOI: 10.26554/sti.2025.10.1.152-164

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why must the entire system be maintained at a high temperature during the filling process of a sodium heat pipe?

- What role does an electric thermostatic drying oven play in the pre-treatment of Fe–Ni/AC catalysts? Essential Guide

- What is the significance of using a laboratory vacuum drying oven during the catalyst recovery phase of depolymerization?

- What role does a high-temperature furnace play in APTO for Vanadium to VO2? Precision Phase Transformation Explained

- What is the catalytic mechanism of methane gas conversion in Ni-Co CNT synthesis? Master Carbon Transformation

- How does a vacuum drying oven provide superior performance for MoS2/C powders? Preserve Purity and Nanostructure

- How is temperature regulated in laboratory furnaces? Master Precision Control for Reliable Results

- Why must raw kaolin undergo heat treatment for DLP 3D printing? Control Viscosity for Precision Printing