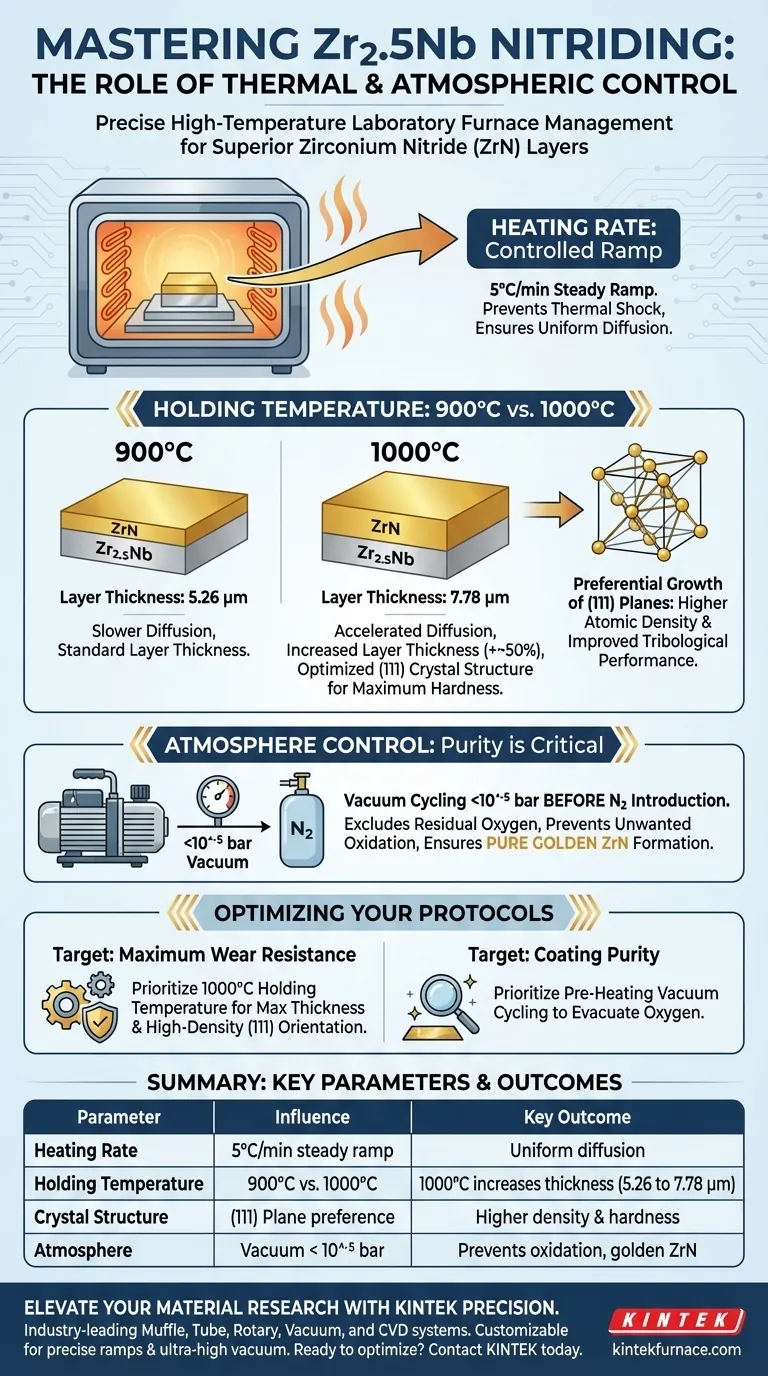

Precise thermal management in a high-temperature laboratory furnace is the decisive factor in forming a high-quality zirconium nitride (ZrN) layer on Zr2.5Nb alloy. A controlled heating rate establishes thermal stability, while the holding temperature directly governs the diffusion kinetics that determine the layer's physical dimensions and mechanical properties.

The difference between a 900°C and a 1000°C holding temperature is not merely thermal; it changes the nitrogen diffusion coefficient, increasing layer thickness by nearly 50% and optimizing the crystal structure for maximum hardness.

Temperature's Influence on Layer Properties

Accelerating Diffusion Kinetics

Temperature is the primary variable controlling the nitrogen diffusion coefficient.

Raising the holding temperature from 900°C to 1000°C significantly accelerates the movement of nitrogen atoms into the alloy substrate.

Impact on Layer Thickness

This acceleration has a measurable impact on the resulting ceramic layer volume.

Under identical processing conditions, the ZrN layer thickness increases from 5.26 micrometers at 900°C to 7.78 micrometers at 1000°C.

Crystallographic Densification

Higher temperatures do more than just thicken the layer; they alter its internal structure.

Processing at 1000°C promotes the preferential growth of (111) crystal planes, which possess a higher atomic density.

This structural change directly translates to increased hardness and improved tribological (wear and friction) performance.

The Role of Heating Rate and Environment

Controlled Heating Ramps

A steady heating rate of 5°C per minute provides the necessary control for these high-temperature processes.

This gradual ramp prevents thermal shock and ensures the sample reaches the target diffusion temperature uniformly.

The Criticality of Atmosphere Control

It is vital to recognize that temperature control is ineffective without atmospheric purity.

High-temperature vacuum tube furnaces must utilize vacuum cycling down to 10^-5 bar before introducing high-purity nitrogen.

Because zirconium has an extreme affinity for oxygen, failing to exclude residual oxygen will result in unwanted oxidation rather than the desired golden ZrN ceramic layer.

Optimizing Your Furnace Protocols

To achieve specific material properties, align your furnace settings with these targeted outcomes:

- If your primary focus is maximum wear resistance: Target a holding temperature of 1000°C to maximize layer thickness (7.78 µm) and promote the high-density (111) crystal orientation.

- If your primary focus is coating purity: Prioritize the pre-heating vacuum cycling steps to ensure oxygen is fully evacuated before the heating ramp begins, preventing surface oxidation.

By mastering the interplay between vacuum integrity and thermal diffusion kinetics, you can engineer zirconium surfaces with precise mechanical capabilities.

Summary Table:

| Parameter | Influence on Zr2.5Nb Nitriding | Key Outcome |

|---|---|---|

| Heating Rate | 5°C/min steady ramp | Prevents thermal shock; ensures uniform diffusion |

| Holding Temperature | 900°C vs. 1000°C | 1000°C increases layer thickness from 5.26 to 7.78 µm |

| Crystal Structure | (111) Plane preference | Higher atomic density and superior surface hardness |

| Atmosphere | Vacuum < 10^-5 bar | Prevents oxidation; ensures pure golden ZrN formation |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect nitride layer requires uncompromising thermal stability and atmospheric purity. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems designed for rigorous laboratory environments. Backed by expert R&D and manufacturing, our high-temp furnaces are fully customizable to meet your specific research needs, from precise heating ramps to ultra-high vacuum cycles.

Ready to optimize your alloy processing? Contact KINTEK today to find the perfect thermal solution for your lab.

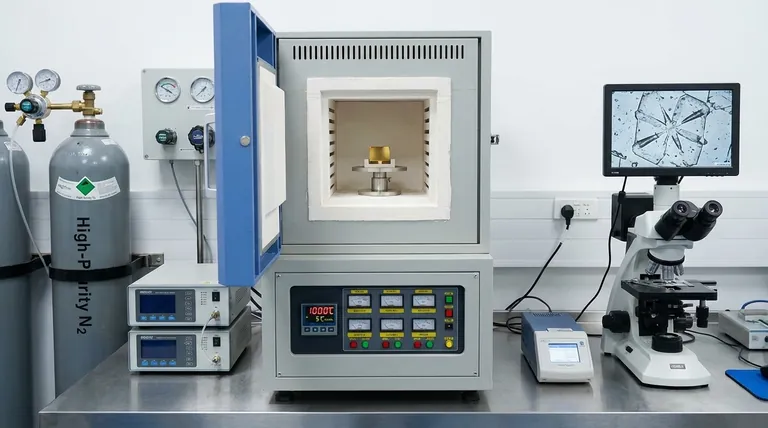

Visual Guide

References

- Longlong Zhang, Yong Luo. Thermal Nitridation Deoxygenation and Biotribological Properties of Zr2.5Nb. DOI: 10.1049/bsb2.70005

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does a high-pressure autoclave with a PTFE liner facilitate GLC synthesis? Ensure Purity and Safety

- What role do RTP or continuous sintering furnaces play in solar cell electrode formation? Optimize Your Firing Process

- Why is it important to choose the right type of heat treatment furnace? Boost Efficiency and Quality in Your Lab or Facility

- Why is a laboratory drying oven necessary for Co-Zr iron oxide nanopowders? Protect Material Integrity & Purity

- What are the advantages of using a vacuum drying oven for MnMgPO4@C3N4? Preserving Photocatalyst Integrity

- How does heat treatment at 500°C affect Ni-Ti shape memory alloys? Optimize Material Performance and Uniformity

- What is a continuous furnace? The High-Volume Solution for Efficient Thermal Processing

- Why is stepped temperature control on a laboratory hotplate necessary for drying sensor active layers? Boost Precision