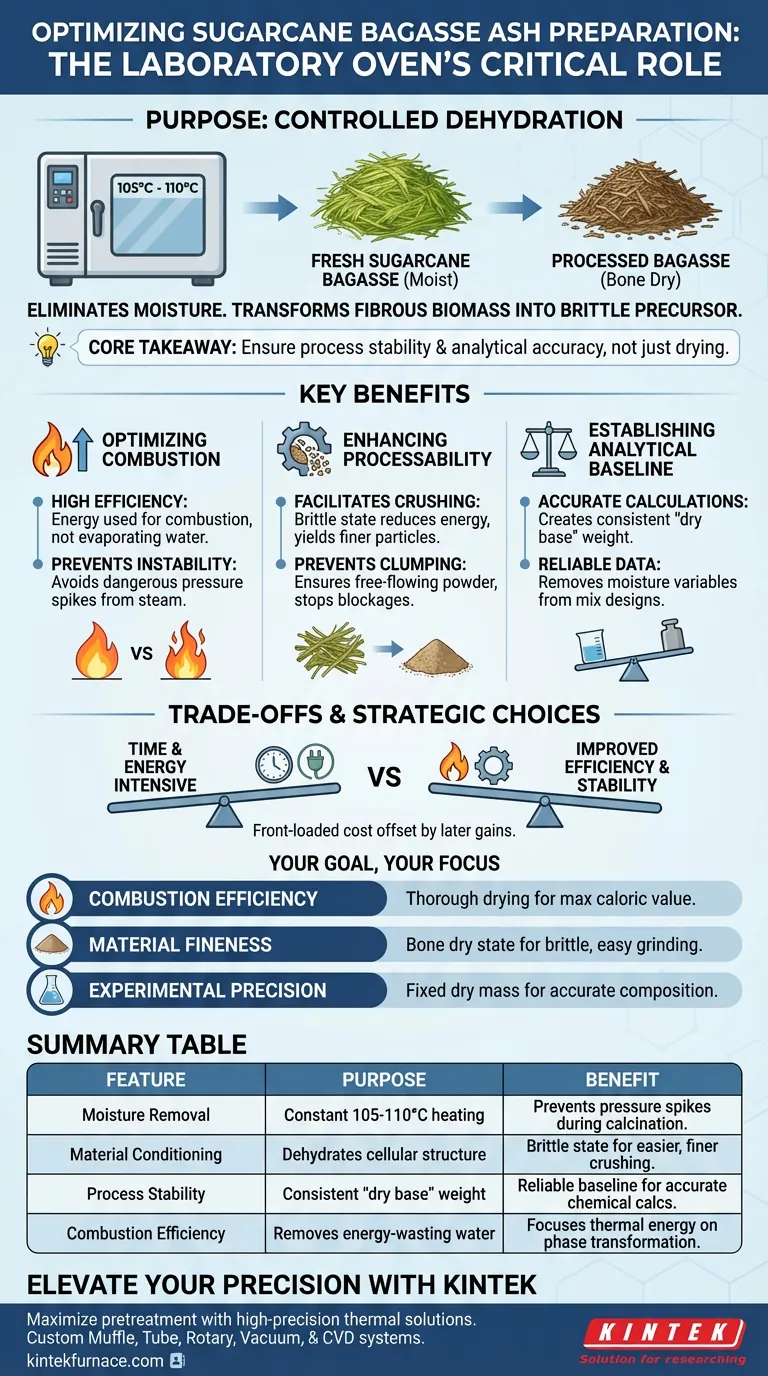

The primary purpose of a laboratory oven in this context is to provide a controlled, constant-temperature environment—typically between 105°C and 110°C—to thoroughly eliminate moisture from fresh sugarcane bagasse. This dehydration step is a prerequisite for downstream processing, ensuring the biomass is physically and chemically prepared for high-temperature combustion and mechanical crushing.

Core Takeaway Use the laboratory oven not merely to dry the material, but to fundamentally alter its physical state. By removing free and adsorbed water, you transform fibrous biomass into a brittle, combustible precursor, ensuring process stability and analytical accuracy in subsequent stages.

Optimizing Combustion and Thermal Stability

The most critical function of the oven is to prepare the material for the intense heat of calcination or carbonization.

Ensuring High Combustion Efficiency

Wet biomass is energetically expensive to burn.

By removing moisture beforehand, you ensure that the energy applied during the high-temperature stages is utilized for combustion and phase transformation, rather than being wasted on evaporating water.

This improves the overall efficiency of the thermal cycle.

Preventing Process Instability

Rapid evaporation during high-temperature processing can be dangerous or disruptive.

If bagasse retains moisture when entering a pre-carbonization stage, the water turns to steam instantly, causing pressure fluctuations.

Oven drying removes free and adsorbed water gently, preventing these spikes and maintaining combustion integrity.

Enhancing Material Processability

Fresh sugarcane bagasse is naturally fibrous and resilient, which presents challenges for mechanical processing. The oven serves as a conditioning tool to change these physical characteristics.

Facilitating the Crushing Process

To produce ash, the bagasse often needs to be ground into a powder.

Drying dehydrates the cellular structure of the bagasse, transitioning it from a tough, fibrous material into a brittle solid.

This brittleness significantly reduces the mechanical energy required to crush the material and results in a finer, more consistent particle size.

Preventing Particle Clumping

Moisture acts as a binding agent for powders.

If the bagasse is not thoroughly dried, the resulting powder may clump or agglomerate during grinding.

A dedicated drying cycle ensures the material remains free-flowing, preventing blockage in grinding equipment.

Establishing a Reliable Analytical Baseline

Beyond physical processing, the laboratory oven ensures that your scientific data remains valid.

Enabling Accurate Chemical Calculations

The moisture content in fresh biomass fluctuates based on storage and humidity.

Drying creates a consistent "dry base" weight.

This ensures that calculations for chemical reagent impregnation or mix designs are based on the actual mass of the bagasse, not the variable weight of the water it holds.

Understanding the Trade-offs

While essential, the drying phase introduces specific constraints that must be managed.

Time Intensity vs. Throughput

Standard protocols often require drying times of up to 24 hours to ensure complete moisture removal.

This creates a bottleneck in the production line; rushing this step results in incomplete drying, which compromises all subsequent stages.

Energy Consumption

Maintaing a constant temperature (e.g., 105°C) for prolonged periods consumes significant electrical energy.

However, this "front-loaded" energy cost is generally offset by the increased efficiency and stability of the later high-temperature combustion processes.

Making the Right Choice for Your Goal

The role of the laboratory oven shifts slightly depending on your specific success metrics.

- If your primary focus is Combustion Efficiency: Prioritize thorough drying to ensure maximum caloric value and minimize heat loss during calcination.

- If your primary focus is Material Fineness: Ensure the bagasse reaches a "bone dry" state to maximize brittleness for easier, finer grinding.

- If your primary focus is Experimental Precision: Use the oven to establish a fixed dry mass, eliminating moisture variables from your chemical composition calculations.

A strictly controlled drying phase is the invisible foundation of high-quality sugarcane bagasse ash production.

Summary Table:

| Feature | Purpose in Pretreatment | Benefit for Ash Preparation |

|---|---|---|

| Moisture Removal | Constant heating at 105°C-110°C | Eliminates water to prevent pressure spikes during calcination. |

| Material Conditioning | Dehydrates fibrous cellular structures | Transforms biomass into a brittle state for easier, finer crushing. |

| Process Stability | Ensures a consistent "dry base" weight | Provides a reliable baseline for accurate chemical calculations. |

| Combustion Efficiency | Removes energy-wasting water | Focuses thermal energy on combustion and phase transformation. |

Elevate Your Biomass Processing Precision

Maximize the efficiency of your laboratory pretreatment with KINTEK’s high-precision thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers advanced Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet the unique dehydration and calcination needs of your research.

Whether you are preparing sugarcane bagasse ash or developing advanced materials, our equipment ensures the thermal stability and analytical accuracy your project demands. Contact KINTEK today to find your custom furnace solution!

Visual Guide

References

- Partial Replacement of Cement with Bagasse Ash in Concrete. DOI: 10.55041/ijsrem44544

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a laboratory facility play in establishing the mass balance for a coke oven operation? Drive Efficiency.

- How does the use of carbon dioxide and a flow meter impact the physical activation of biochar? Master Pore Development

- What is the purpose of maintaining a 70°C environment in Li-NASICON experiments? Accelerate Your Battery Research

- Why is an industrial forced air drying oven required for drying banana slices? Unlock Precision & Nutritional Quality

- What is the function of a precise heating system during the hydrolysis of palm kernel oil? Optimize Your Fatty Acid Yield

- How does a temperature-controlled experimental platform support the testing of Mn3O4 memristor stability?

- Why is precise temperature control below 1700°C required for beta-SiC? Master Your Cubic Silicon Carbide Synthesis

- Why is a rapid cooling process necessary for BZSM nanophosphors? Secrets of Metastable Phase Retention