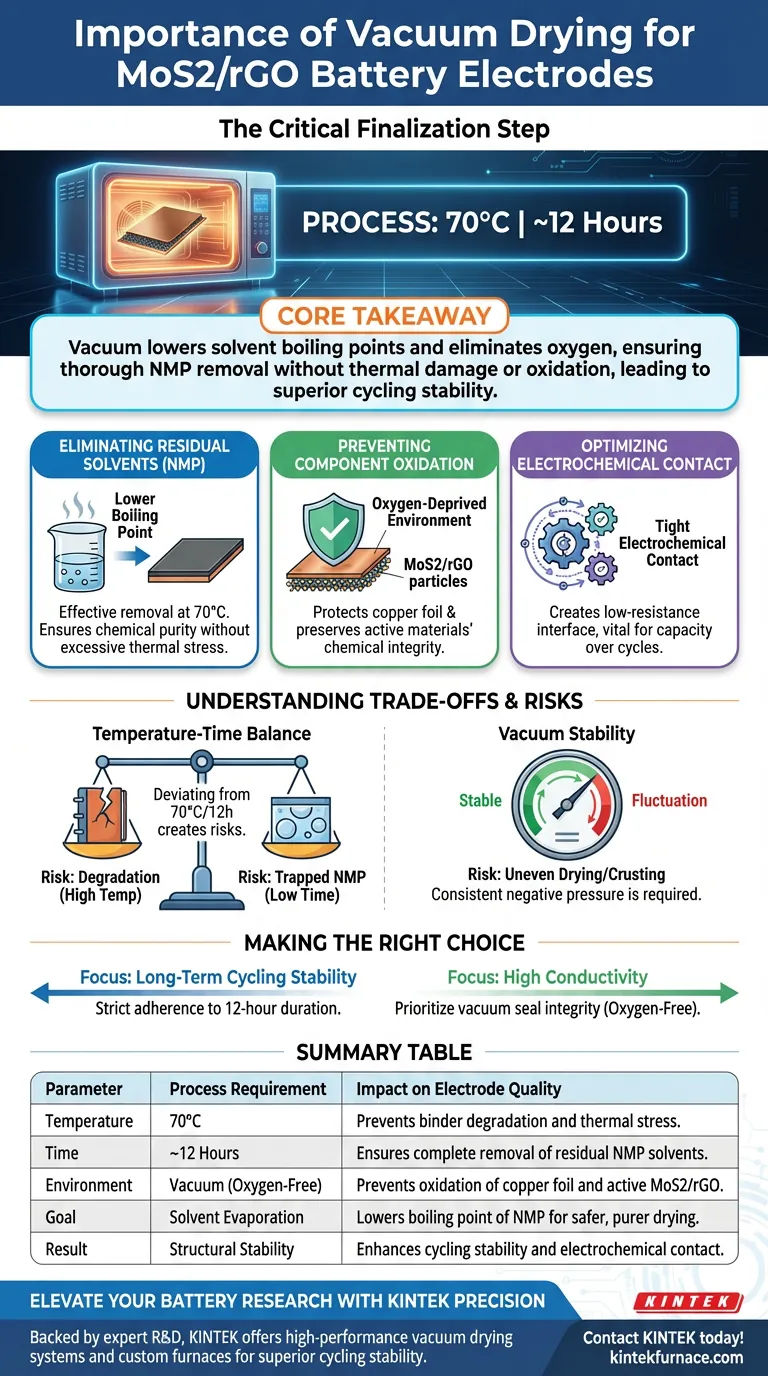

The vacuum drying oven acts as the critical finalization step in the fabrication of Molybdenum Disulfide/Reduced Graphene Oxide (MoS2/rGO) battery electrodes. Specifically, it involves treating the coated copper foil at 70°C for approximately 12 hours to ensure the complete removal of residual solvents, primarily N-Methyl-2-pyrrolidone (NMP), from the slurry mixture. This process is essential for stabilizing the physical structure of the electrode before battery assembly.

Core Takeaway While standard heat removes moisture, a vacuum drying oven is indispensable because it lowers the boiling point of solvents and eliminates oxygen. This ensures the thorough removal of NMP without thermally damaging the binder or oxidizing the sensitive MoS2/rGO materials and copper collectors, directly resulting in superior cycling stability.

The Critical Functions of Vacuum Drying

The preparation of MoS2/rGO electrodes is not merely about "drying" in the traditional sense; it is about chemical preservation and structural bonding.

Eliminating Residual Solvents (NMP)

The slurry used to coat battery electrodes typically contains N-Methyl-2-pyrrolidone (NMP), a solvent with a high boiling point.

Under normal atmospheric pressure, removing NMP requires high temperatures that could damage other components. The vacuum environment significantly lowers the boiling point of NMP. This allows the oven to effectively vaporize and remove the solvent at a moderate 70°C, ensuring the electrode is chemically pure without subjecting it to excessive thermal stress.

Preventing Component Oxidation

Both the copper foil current collector and the active materials (MoS2/rGO) are sensitive to oxidation.

Drying in a standard oven exposes these materials to hot air, which can lead to the formation of insulating oxide layers. The vacuum oven operates in an oxygen-deprived environment, protecting the copper foil from corroding and preserving the chemical integrity of the active sulfur and carbon components.

Optimizing Electrochemical Contact

The performance of a battery relies on the path electrons take through the material.

By removing trace solvents and preventing oxidation, the vacuum process ensures tight electrochemical contact. It allows the active materials, conductive additives, and binders to fuse effectively with the current collector. This creates a low-resistance interface, which is vital for maintaining capacity over hundreds of charge-discharge cycles.

Understanding the Trade-offs and Risks

While vacuum drying is the superior method for electrode preparation, it introduces specific process variables that must be managed.

The Temperature-Time Balance

The primary reference specifies a protocol of 70°C for 12 hours. Deviating from this balance creates risks.

Increasing the temperature to speed up the process can degrade the polymer binders or anneal the copper foil, making it brittle. Conversely, reducing the time may leave trace NMP trapped deep within the porous structure. Residual NMP can react with the electrolyte later, leading to dangerous side reactions and battery failure.

Vacuum Stability

The process relies on a consistent negative pressure.

Fluctuations in vacuum pressure can lead to uneven drying or "crusting," where the surface dries faster than the interior, trapping solvents inside. Consistent pressure is required to draw solvents out from the deepest pores of the electrode coating.

Making the Right Choice for Your Goal

The vacuum drying step is not a passive waiting period; it is an active control measure for battery quality.

- If your primary focus is Long-Term Cycling Stability: Adhere strictly to the 12-hour duration to ensure zero residual solvent remains to react with the electrolyte.

- If your primary focus is High Conductivity: Prioritize the vacuum seal integrity to ensure a completely oxygen-free environment, preventing insulating oxides from forming on the copper collector.

By controlling the atmosphere and temperature precisely, you transform a wet slurry into a high-performance electrochemical component.

Summary Table:

| Parameter | Process Requirement | Impact on Electrode Quality |

|---|---|---|

| Temperature | 70°C | Prevents binder degradation and thermal stress. |

| Time | ~12 Hours | Ensures complete removal of residual NMP solvents. |

| Environment | Vacuum (Oxygen-Free) | Prevents oxidation of copper foil and active MoS2/rGO. |

| Goal | Solvent Evaporation | Lowers boiling point of NMP for safer, purer drying. |

| Result | Structural Stability | Enhances cycling stability and electrochemical contact. |

Elevate Your Battery Research with KINTEK Precision

Don't let residual solvents or oxidation compromise your electrochemical breakthroughs. Backed by expert R&D and manufacturing, KINTEK offers high-performance vacuum drying systems, Muffle, Tube, Rotary, and CVD furnaces—all fully customizable to meet the rigorous demands of battery electrode fabrication. Whether you are processing MoS2/rGO or advanced nanomaterials, our equipment ensures the precise thermal control and atmospheric integrity you need for superior cycling stability.

Ready to optimize your lab's drying protocol? Contact KINTEK today to discuss your unique needs!

Visual Guide

References

- Anna A. Vorfolomeeva, Lyubov G. Bulusheva. Molybdenum Disulfide and Reduced Graphene Oxide Hybrids as Anodes for Low-Temperature Lithium- and Sodium-Ion Batteries. DOI: 10.3390/nano15110824

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the primary function of glass matrices in HLW vitrification? Achieve Safe Radioactive Waste Immobilization

- What are the advantages and disadvantages of dental porcelain? Achieve a Perfect Balance of Aesthetics & Durability

- How does the analysis of optimized process paths assist in lab equipment selection? Expert Guide for Research Success

- How does a temperature-programmed system influence molybdenum carbide formation? Expert Catalyst Synthesis Guide

- Why is temperature control precision critical for a sample heating furnace? Master Ti-V-Cr Alloy Oxidation Kinetics

- Importance of NaH2PO2 Layout in V-Ni3S2/NF Phosphorization: Ensuring Uniform 3D Doping

- Why are varied heating rates applied during oil shale pyrolysis? Optimize Kinetics and Technical Validation

- How is temperature regulated in laboratory furnaces? Master Precision Control for Reliable Results