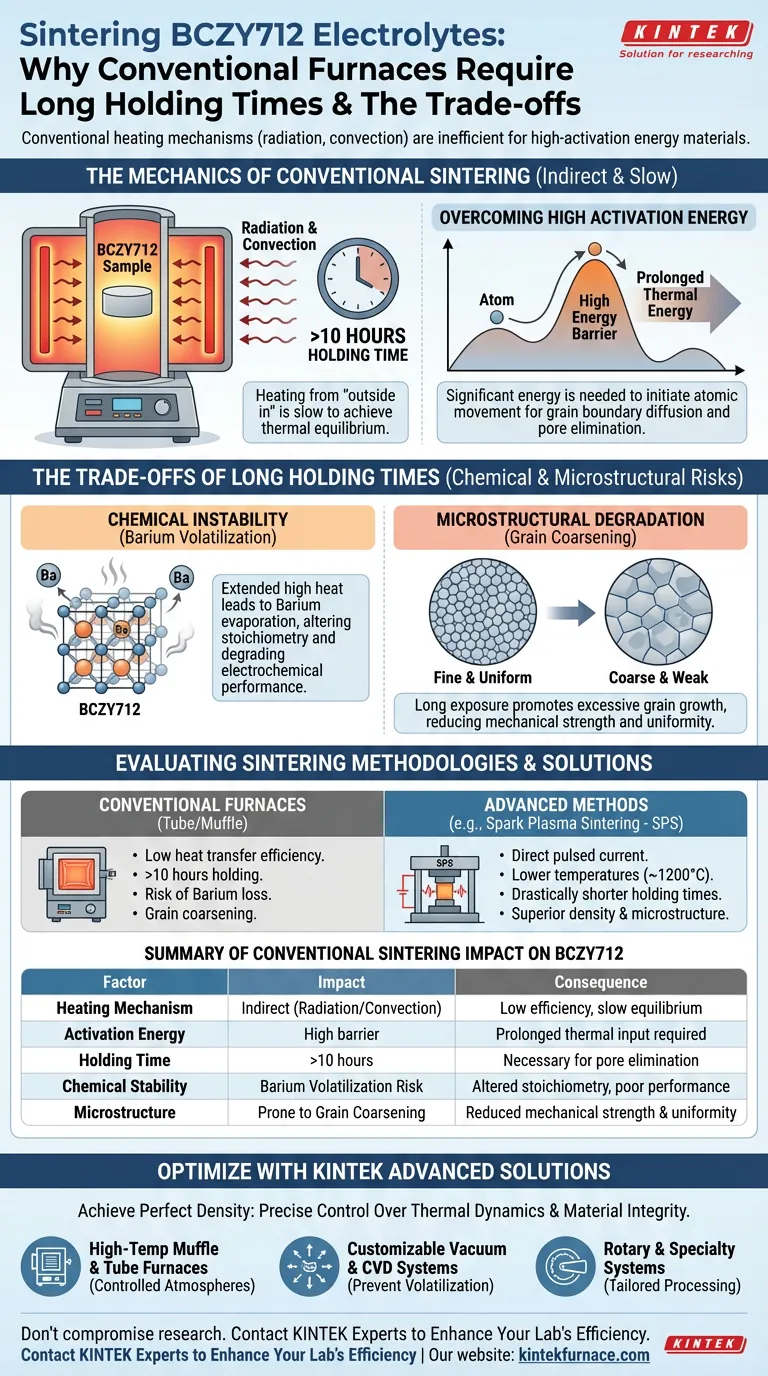

Conventional high-temperature tube or muffle furnaces rely on external heating mechanisms like radiation and convection, which inherently suffer from lower heat transfer efficiency compared to direct methods. Because BCZY712 ceramics possess a high sintering activation energy, these furnaces must maintain high temperatures for extended periods—often exceeding 10 hours—to drive the necessary grain boundary diffusion and successfully eliminate pores.

The necessity for long holding times stems from the inefficiency of indirect heating combined with the material's high activation energy. While this duration is required to densify the ceramic using conventional means, it introduces significant risks regarding material stability and microstructural integrity.

The Mechanics of Conventional Sintering

External Heating Inefficiency

Tube and muffle furnaces operate by heating the sample from the "outside in." They depend primarily on radiation and convection to transfer thermal energy from the heating elements to the ceramic sample.

This process is inherently slower and less efficient than direct heating methods (such as applying current directly to the sample). Consequently, the system requires more time to achieve thermal equilibrium and drive the sintering process.

Overcoming High Activation Energy

BCZY712 electrolytes are not easily densified. They possess a high sintering activation energy, meaning a significant energy barrier must be overcome to initiate the atomic movements required for sintering.

To surmount this barrier using the less efficient heat transfer of conventional furnaces, the material must be exposed to heat for a prolonged duration. A holding time of over 10 hours is typically necessary to ensure sufficient grain boundary diffusion and pore elimination.

The Trade-offs of Long Holding Times

Chemical Instability

The extended duration required for conventional sintering comes at a chemical cost. Maintaining high temperatures for long periods frequently leads to barium volatilization.

When barium evaporates from the ceramic lattice, it alters the material's stoichiometry. This degradation can negatively impact the final electrochemical performance of the electrolyte.

Microstructural Degradation

Time is the enemy of microstructural uniformity in this context. The long holding times promote grain coarsening, where grains grow excessively large rather than remaining fine and uniform.

While the goal is to eliminate pores, the side effect of this extended heat exposure is often a microstructure with reduced mechanical strength and uniformity compared to rapid sintering techniques.

Evaluating Sintering Methodologies

When processing BCZY712 electrolytes, the choice of furnace defines your processing parameters and final material quality.

- If you are restricted to conventional furnaces: You must account for lower heat transfer efficiency by planning for holding times exceeding 10 hours, while actively monitoring for barium loss.

- If you require superior density and microstructure: Consider alternative methods like Spark Plasma Sintering (SPS), which uses direct pulsed current and pressure to lower temperatures (to ~1200°C) and drastically shorten holding times.

Understanding the thermal limitations of your equipment is the first step toward optimizing the performance of proton-conducting ceramics.

Summary Table:

| Factor | Impact on BCZY712 Sintering | Consequence of Conventional Heating |

|---|---|---|

| Heating Mechanism | Indirect (Radiation/Convection) | Low heat transfer efficiency; slow equilibrium |

| Activation Energy | High barrier for densification | Requires prolonged thermal energy input |

| Holding Time | Exceeds 10 hours | Necessary for pore elimination via diffusion |

| Chemical Stability | Risk of Barium volatilization | Altered stoichiometry & poor performance |

| Microstructure | Prone to grain coarsening | Reduced mechanical strength and uniformity |

Optimize Your Advanced Ceramic Sintering Today

Achieving the perfect density for BCZY712 electrolytes requires more than just high heat—it requires precise control over thermal dynamics and material integrity. KINTEK provides industry-leading solutions designed to address the challenges of high-activation energy materials.

Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory equipment including:

- High-Temperature Muffle & Tube Furnaces for controlled atmospheric sintering.

- Customizable Vacuum & CVD Systems to prevent chemical volatilization.

- Rotary & Specialty Systems tailored for unique material processing needs.

Don't let inefficient heating cycles or grain coarsening compromise your research results. Our technical experts are ready to help you select or customize the ideal high-temperature system for your specific application.

Contact KINTEK Experts to Enhance Your Lab’s Efficiency

Visual Guide

References

- Pallavi Bhaktapralhad Jagdale, Manav Saxena. Agri-waste derived electroactive carbon–iron oxide nanocomposite for oxygen reduction reaction: an experimental and theoretical study. DOI: 10.1039/d4ra01264j

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What role does a laboratory muffle furnace play in cotton waste biochar? Precision Pyrolysis for Carbonization

- What conditions does a muffle furnace provide for evaluating the oxidation stability of HfOC/SiOC fiber mats?

- What is the function of a high-temperature lift furnace in the sintering process of SSZ electrolyte pellets?

- How do the chamber sizes of muffle furnaces and drying ovens compare? Key Differences Explained

- Why is a laboratory muffle furnace essential for the activation of catalysts? Optimize Your Catalyst Performance

- How does a muffle furnace convert goethite to hematite? Unlock Precision Thermal Dehydration

- How is a muffle furnace utilized in environmental analysis? Essential for Precise Organic and Inorganic Composition Testing

- What role does a high-temperature calcination furnace play in HZSM-5 zeolite? Powering Catalyst Activation