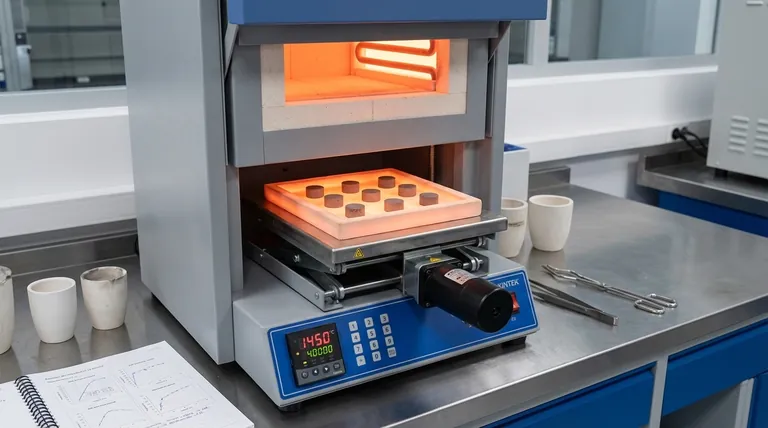

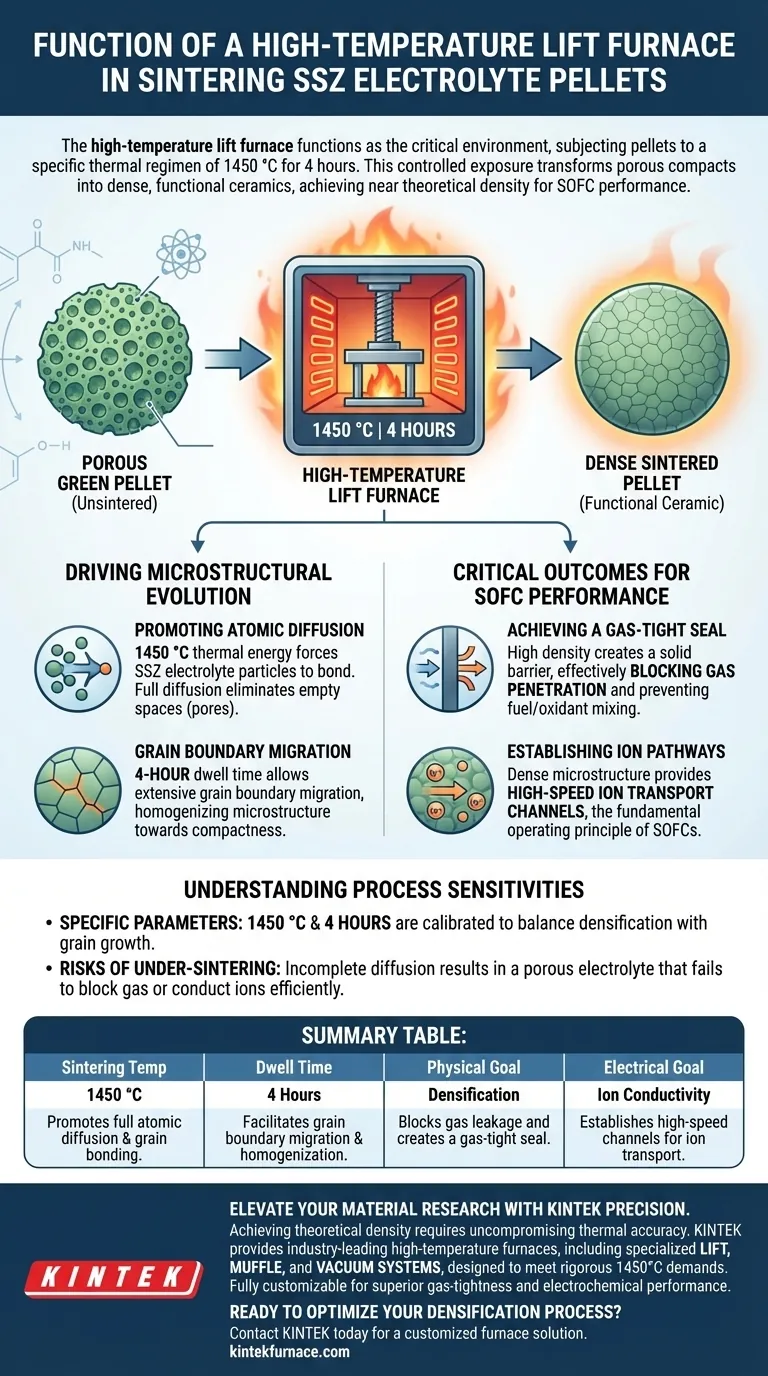

The high-temperature lift furnace functions as the critical environment for sintering SSZ electrolyte pellets, subjecting them to a specific thermal regimen of 1450 °C for 4 hours. This controlled exposure promotes full diffusion and grain boundary migration, transforming the material from a porous compact into a dense, functional ceramic.

The core objective of this process is achieving densification near the theoretical density. This state is essential to create a component that physically blocks gas leakage while simultaneously acting as a high-speed conductor for ions in Solid Oxide Fuel Cells (SOFC).

Driving Microstructural Evolution

Promoting Atomic Diffusion

The furnace provides an ultra-high temperature environment of 1450 °C. This thermal energy is the catalyst that forces SSZ electrolyte particles to bond.

At this temperature, the material undergoes full diffusion. The individual particles merge, effectively eliminating the empty spaces (pores) that exist in the "green" (unsintered) state.

Grain Boundary Migration

The sintering process is not instant; it requires a sustained duration of 4 hours. This dwell time allows for extensive grain boundary migration.

As grain boundaries move and settle, the microstructure of the SSZ pellet homogenizes. This migration is the mechanism that drives the material toward its most compact, solid form.

Critical Outcomes for SOFC Performance

Achieving a Gas-Tight Seal

The primary physical result of this heating process is densification. The furnace ensures the pellets reach a density very close to the theoretical maximum for the material.

This high density is non-negotiable for SOFC operation. It creates a solid barrier that effectively blocks gas penetration, preventing fuel and oxidant gases from mixing directly.

Establishing Ion Pathways

Beyond physical sealing, the furnace treatment dictates the electrochemical properties of the pellet. The dense microstructure provides high-speed ion transport channels.

These channels allow oxygen ions to move freely through the electrolyte. This transport capability is the fundamental operating principle of a Solid Oxide Fuel Cell.

Understanding the Process Sensitivities

The Necessity of Specific Parameters

The specific combination of 1450 °C and 4 hours is not arbitrary. This recipe is calibrated to balance densification with grain growth.

Risks of Under-Sintering

If the furnace fails to maintain the target temperature or duration, diffusion will be incomplete. This results in a porous electrolyte that fails to block gas or conduct ions efficiently.

Optimizing Your Sintering Strategy

To ensure your SSZ electrolytes perform correctly in a fuel cell stack, you must prioritize strict adherence to the thermal profile.

- If your primary focus is safety and sealing: Ensure the furnace reliably reaches 1450 °C to maximize density and prevent gas leakage.

- If your primary focus is electrical efficiency: Verify the 4-hour dwell time is fully met to establish the continuous grain structure required for high-speed ion transport.

The high-temperature lift furnace is not just a heater; it is the tool that defines the structural and electrochemical integrity of the final fuel cell.

Summary Table:

| Parameter | Specification | Function/Impact |

|---|---|---|

| Sintering Temp | 1450 °C | Promotes full atomic diffusion & grain bonding |

| Dwell Time | 4 Hours | Facilitates grain boundary migration & homogenization |

| Physical Goal | Densification | Blocks gas leakage and creates a gas-tight seal |

| Electrical Goal | Ion Conductivity | Establishes high-speed channels for ion transport |

Elevate Your Material Research with KINTEK Precision

Achieving the theoretical density of SSZ electrolyte pellets requires uncompromising thermal accuracy. KINTEK provides industry-leading high-temperature furnaces, including specialized lift, muffle, and vacuum systems, designed to meet the rigorous 1450°C demands of SOFC manufacturing. Backed by expert R&D and manufacturing, our systems are fully customizable to ensure your sintering protocols yield superior gas-tightness and electrochemical performance.

Ready to optimize your densification process? Contact KINTEK today for a customized furnace solution.

Visual Guide

References

- Hao Dong, Zhaotong Wei. Study on Performance and Preparation of Lanthanum-Strontium-Iron-Chromium Electrodes for Using in Symmetric SOFC. DOI: 10.54097/8d6pg665

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the function of a muffle furnace in the synthesis process of Ag2S1-xTex materials? Precision Thermal Processing

- How do muffle furnaces contribute to drug testing in pharmaceuticals? Ensure Purity and Compliance with Precision

- What is the core function of a laboratory muffle furnace in diatomaceous earth conversion? | KINTEK

- How does the muffle furnace prevent run-away conditions? Ensure Safe, Reliable High-Temperature Operations

- What role does a resistance furnace play in ZK61 magnesium alloy treatment? Mastering Homogenization & Microstructure

- How does a high-temperature muffle furnace control the silver ion release rate? Master Precision Geopolymer Sintering

- How are box furnaces used in industrial applications? Versatile Batch Processing for Heat Treating and More

- Why is a heating furnace required for thermal holding before hot extrusion? Optimize Material Flow & Density