In industrial settings, box furnaces are the workhorses of thermal processing. They are used for a vast range of batch-oriented applications, from heat-treating steel components and firing advanced ceramics to testing new materials in a laboratory. Their fundamental design—a simple, front-loading chamber—makes them incredibly versatile for handling diverse parts and materials that require uniform heating in a controlled cycle.

A box furnace is best understood as a general-purpose tool for batch processing. Its primary value lies in its flexibility to handle a wide variety of part sizes, shapes, and thermal processes, though this comes with trade-offs compared to more specialized furnaces designed for specific atmospheres or continuous production.

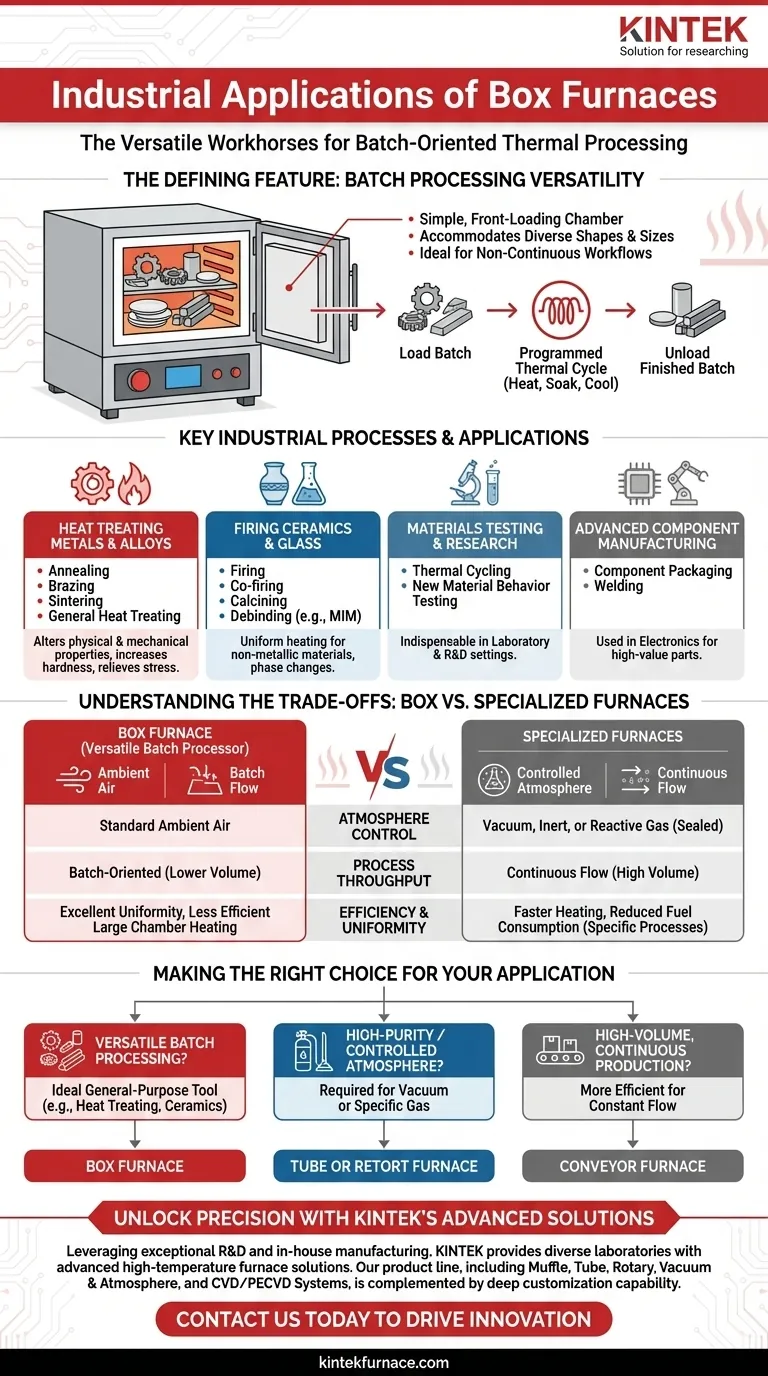

The Defining Feature: Batch Processing Versatility

The utility of a box furnace stems directly from its straightforward design. Understanding this core concept is key to knowing when and why to use one.

A Simple, Accessible Chamber

A box furnace, also known as a muffle furnace, consists of an insulated cabinet with a front-loading door that opens to a single, contained chamber. This simple configuration is its greatest strength.

It allows operators to easily load and unload items of various dimensions, from a single large component to a tray of many small parts.

Accommodating Diverse Shapes and Sizes

Unlike a tube furnace, which is limited to smaller, uniform samples or continuous material flows, a box furnace can accommodate bulky or irregularly shaped objects.

This makes it the default choice for general heat treatment of manufactured parts, tooling, and fixtures.

The Batch-Oriented Workflow

The box furnace is designed for a distinct workflow: load a batch of materials, run a programmed thermal cycle (heating, soaking, cooling), and unload the finished batch.

This workflow is ideal for many manufacturing, repair, and research scenarios that do not require a continuous flow of material.

Key Industrial Processes and Applications

The versatility of the box furnace means it supports a wide array of critical thermal processes across numerous industries.

Heat Treating Metals and Alloys

This is a primary application. Processes like annealing, brazing, sintering, and general heat treating are performed to alter the physical and mechanical properties of metals.

These treatments can increase hardness, relieve internal stresses, or prepare a material for further manufacturing steps.

Firing Ceramics and Glass

The uniform heating environment is perfect for processing non-metallic materials. Box furnaces are used for firing and co-firing ceramics, calcining powders to induce phase changes, and working with glass.

They are also essential for debinding processes, where a binder material is slowly burned out of a "green" part, such as in metal injection molding (MIM).

Materials Testing and Research

In laboratory and R&D settings, box furnaces are indispensable for materials testing. They are used to perform thermal cycling to test durability or to determine how a new material behaves at elevated temperatures.

Advanced Component Manufacturing

Box furnaces play a role in producing high-value components. In electronics, they are used for processes like component packaging and welding.

Understanding the Trade-offs: Box Furnace vs. Specialized Furnaces

While incredibly versatile, a box furnace is not the optimal solution for every thermal processing need. Its limitations define when a more specialized furnace is required.

Atmosphere Control

Standard box furnaces operate in ambient air. For processes that require a specific atmosphere—such as a vacuum, an inert gas like argon, or a reactive gas—a retort or tube furnace is necessary. These furnaces are sealed to prevent contamination and allow for precise atmospheric control.

Process Throughput

The batch nature of a box furnace is a limitation for high-volume production. When a continuous flow of product is needed, a conveyor furnace or rotary furnace is far more efficient, as parts move through heating zones without stopping the line.

Heating Efficiency and Uniformity

While modern box furnaces have excellent temperature uniformity, their large chambers can be less efficient to heat than smaller, specialized furnaces. A retort furnace, for example, often offers faster heating times and reduced fuel consumption for specific, repeatable processes.

Making the Right Choice for Your Application

Selecting the correct furnace depends entirely on the requirements of your process, material, and production volume.

- If your primary focus is versatile batch processing: The box furnace is your ideal general-purpose tool for handling various parts and processes like heat treating or ceramics firing.

- If your primary focus is high-purity processing or controlled atmospheres: A tube or retort furnace is necessary for applications requiring vacuum or specific gas environments.

- If your primary focus is high-volume, continuous production: A conveyor furnace would be a more efficient choice than a batch-style box furnace.

Understanding the box furnace as a foundational, versatile batch processor empowers you to leverage its strengths while recognizing when a more specialized tool is required for the job.

Summary Table:

| Application | Key Uses | Industries |

|---|---|---|

| Heat Treating | Annealing, brazing, sintering | Manufacturing, Automotive |

| Ceramics & Glass | Firing, calcining, debinding | Electronics, Aerospace |

| Materials Testing | Thermal cycling, R&D | Laboratories, Research |

| Component Manufacturing | Packaging, welding | Electronics, High-Tech |

Unlock Precision and Efficiency with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need versatile batch processing or specialized atmospheres, we deliver reliable performance tailored to your needs.

Contact us today to discuss how our furnaces can enhance your industrial applications and drive innovation in your projects. Get in touch now!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety