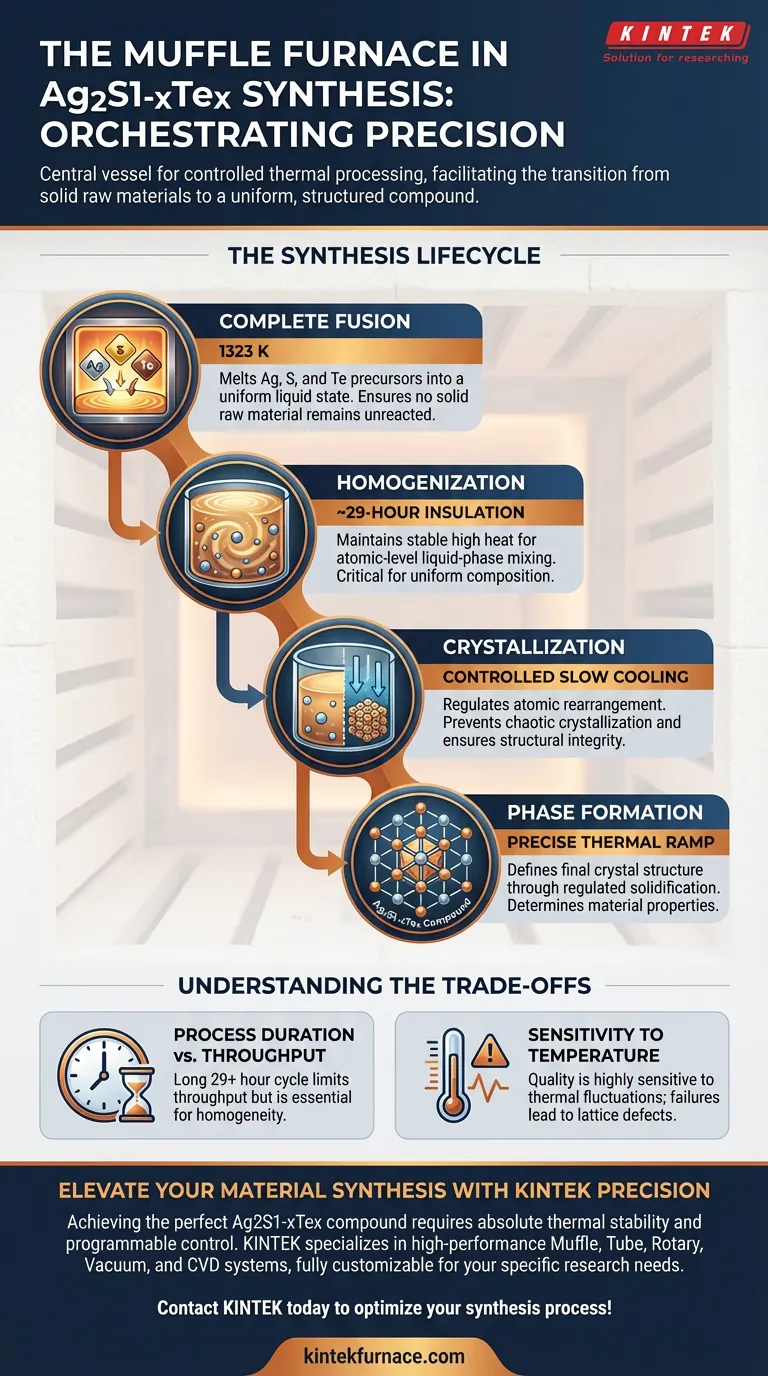

In the synthesis of Ag2S1-xTex materials, the muffle furnace serves as the central vessel for controlled thermal processing, specifically designed to melt Silver (Ag), Sulfur (S), and Tellurium (Te) at 1323 K. Its primary utility lies in maintaining this high temperature to facilitate the transition of solid raw materials into a uniform liquid state.

The muffle furnace acts as a precision instrument that orchestrates the synthesis lifecycle: complete melting of precursors, long-duration liquid-phase homogenization, and the regulation of cooling rates to define crystal structure.

The Role of Precise Thermal Control

Achieving Complete Fusion

The furnace creates the necessary thermal energy to reach 1323 K. At this specific temperature, the solid Silver, Sulfur, and Tellurium precursors are forced into a complete melt. This ensures that no solid raw material remains unreacted before the mixing phase begins.

Facilitating Liquid-Phase Homogenization

Once melted, the material requires time to mix at the atomic level. The muffle furnace provides an extended insulation period of approximately 29 hours.

During this phase, the liquid mixture is held at a stable temperature. This duration is critical for allowing the different elements to diffuse evenly, resulting in a homogenous liquid solution essential for consistent material properties.

Phase Formation and Crystallization

Regulating the Cooling Process

After homogenization, the muffle furnace manages the transition from liquid back to solid. It does not simply cut power; it facilitates a slow cooling process.

Controlling Crystal Growth

This controlled temperature drop is a critical physical condition. By cooling slowly, the furnace allows for ordered atomic rearrangement and precise initial phase formation. This control prevents the chaotic crystallization that might occur with rapid cooling, ensuring the final material has the desired structural integrity.

Understanding the Trade-offs

Process Duration vs. Throughput

The primary limitation of this synthesis method is the time investment. Dedicating equipment to a single batch for over 29 hours (plus cooling time) significantly limits throughput compared to faster, less precise methods.

Sensitivity to Temperature Fluctuations

While muffle furnaces are designed for stability, the quality of Ag2S1-xTex is highly sensitive to the thermal environment. Any failure to maintain the 1323 K hold or the specific cooling ramp can lead to lattice defects or poor crystallinity, similar to issues seen in other sensitive metallurgical processes.

Making the Right Choice for Your Goal

Depending on your specific synthesis requirements, prioritize the furnace parameters as follows:

- If your primary focus is Material Homogeneity: Ensure the furnace can maintain stable insulation at 1323 K for the full 29-hour duration to guarantee liquid-phase mixing.

- If your primary focus is Crystal Quality: Prioritize a furnace with programmable cooling ramps to precisely control the solidification and phase formation process.

The muffle furnace is not just a heater, but a critical tool for enforcing the thermodynamic conditions required to turn raw elements into a structured, homogenous compound.

Summary Table:

| Synthesis Phase | Temperature / Duration | Muffle Furnace Function |

|---|---|---|

| Complete Fusion | 1323 K | Melts Ag, S, and Te precursors into a uniform liquid state. |

| Homogenization | 29-Hour Insulation | Maintains stable high heat for atomic-level liquid-phase mixing. |

| Crystallization | Controlled Slow Cooling | Regulates atomic rearrangement to prevent defects and ensure integrity. |

| Phase Formation | Precise Thermal Ramp | Defines final crystal structure through regulated solidification. |

Elevate Your Material Synthesis with KINTEK Precision

Achieving the perfect Ag2S1-xTex compound requires more than just heat; it requires absolute thermal stability and programmable control. At KINTEK, we specialize in high-performance thermal solutions designed for rigorous laboratory standards.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your specific research needs. Whether you require precise 1323 K maintenance for long-duration homogenization or advanced cooling ramps for crystal growth, our furnaces provide the reliability your materials demand.

Ready to optimize your synthesis process? Contact KINTEK today to discuss your custom furnace requirements with our technical team!

Visual Guide

References

- Kosuke Sato, Tsunehiro Takeuchi. Composition, time, temperature, and annealing-process dependences of crystalline and amorphous phases in ductile semiconductors Ag2S1−<i>x</i>Te<i>x</i> with <i>x</i> = 0.3–0.6. DOI: 10.1063/5.0180950

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a laboratory muffle furnace maintain an efficient environment for ilmenite reduction? Optimize Heat Treatment

- What materials are used in a box type resistance furnace's structure? Discover the Key Materials for Durability and Efficiency

- How is a muffle furnace utilized during the high-temperature annealing of forged TiAl-SiC composites?

- How are Muffle furnaces utilized in electronic material processing? Achieve Precise Thermal Control for Electronics

- What is the purpose of an air-chamber laboratory furnace? Master Inorganic Glass and Ceramic Conversion

- How is a Muffle furnace used in environmental treatment? Essential for Waste Analysis and Small-Scale Incineration

- How does the exhaust system in some muffle furnaces contribute to safety? Prevent Hazards and Ensure Safe Operation

- Why is precise temperature control in a muffle furnace critical during the conversion of FeOOH to Fe2O3?