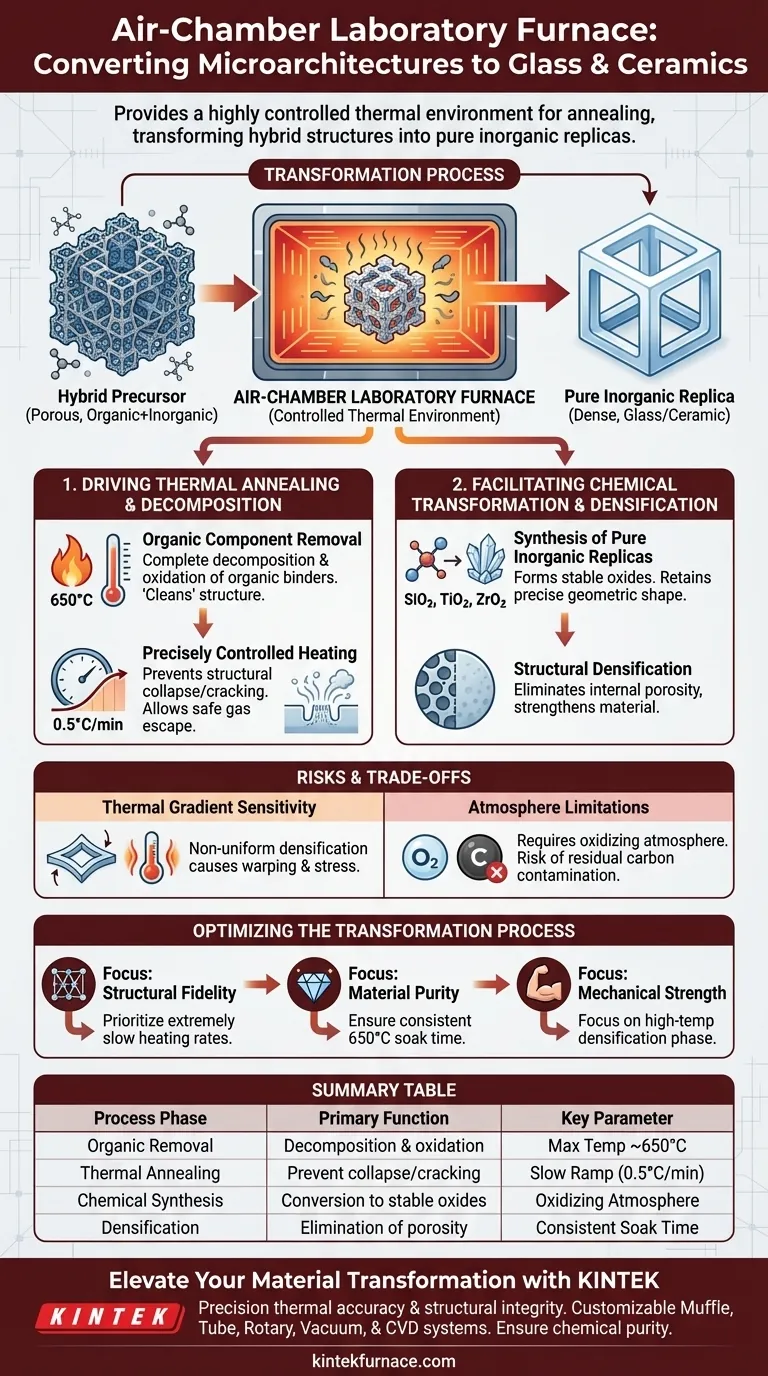

The primary purpose of an air-chamber laboratory furnace in this process is to provide a highly controlled thermal environment for the annealing of precursor microarchitectures. It acts as the critical catalyst for transforming hybrid organic-inorganic structures into pure, dense inorganic replicas—such as glass or ceramics—by precisely managing heating rates and temperature gradients.

The furnace facilitates the transition from hybrid precursors to pure inorganic states by driving the complete oxidation of organic binders and the subsequent densification of the inorganic skeleton. This controlled thermal processing is the only way to ensure the final microarchitecture maintains its structural integrity and chemical purity.

Driving Thermal Annealing and Decomposition

Organic Component Removal

The furnace maintains high temperatures, often reaching 650 °C, to ensure the complete decomposition and oxidation of organic components within the hybrid structures.

By burning away these organic binders, the furnace leaves behind only the intended inorganic framework, effectively "cleaning" the structure at a molecular level.

Precisely Controlled Heating Rates

A slow heating rate, such as 0.5 °C per minute, is critical to prevent structural collapse or cracking during the material transition.

These controlled ramps allow gases generated from decomposing organics to escape the architecture slowly, preventing internal pressure buildup that could shatter the delicate micro-features.

Facilitating Chemical Transformation and Densification

Synthesis of Pure Inorganic Replicas

High-temperature exposure within the furnace promotes the chemical transformation of "pre-glass" materials into stable inorganic oxides like SiO2, TiO2, or ZrO2.

This transformation results in a pure inorganic state that retains the precise geometric shape of the original precursor while gaining the properties of glass or ceramics.

Structural Densification

The furnace provides the thermal energy required for the densification of the inorganic precursors.

This process eliminates internal porosity and strengthens the material, turning a fragile, porous hybrid into a robust, solid glass or ceramic micro-structure.

Understanding the Trade-offs and Risks

Thermal Gradient Sensitivity

Uneven temperature distribution within the furnace chamber can lead to non-uniform densification, which often causes warping or internal stress.

Precise gradient management is required to ensure the entire microarchitecture matures at the same rate; otherwise, the final part may deviate from its intended dimensions.

Atmosphere Limitations

As an "air-chamber" furnace, the process relies on an oxidizing atmosphere, which is necessary for burning organics but may be unsuitable for materials sensitive to oxygen at high temperatures.

Furthermore, failure to ensure sufficient airflow within the chamber can result in residual carbon contamination, which compromises the optical and mechanical purity of the final glass or ceramic.

Optimizing the Transformation Process

Success in converting microarchitectures depends on balancing thermal precision with the specific chemical requirements of your precursor material.

- If your primary focus is structural fidelity: Prioritize extremely slow heating rates to allow for safe outgassing of organic components without distorting the architecture.

- If your primary focus is material purity: Ensure the furnace maintains a consistent 650 °C soak time to guarantee full oxidation and the total removal of organic residues.

- If your primary focus is mechanical strength: Focus on the final densification phase, ensuring the temperature is high enough to allow the inorganic precursors to reach their maximum density.

Mastering the furnace’s thermal profile is the defining factor in successfully migrating from a hybrid precursor to a high-performance inorganic microarchitecture.

Summary Table:

| Process Phase | Primary Function | Key Parameter |

|---|---|---|

| Organic Removal | Decomposition & oxidation of binders | Max Temp ~650°C |

| Thermal Annealing | Preventing structural collapse/cracking | Slow Ramp (0.5°C/min) |

| Chemical Synthesis | Conversion to stable oxides (SiO2, TiO2) | Oxidizing Atmosphere |

| Densification | Elimination of porosity & strengthening | Consistent Soak Time |

Elevate Your Material Transformation with KINTEK

Precision is the difference between a shattered precursor and a perfect ceramic replica. At KINTEK, we understand that your research depends on thermal accuracy and structural integrity.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are synthesizing high-purity glass or complex ceramic microarchitectures, our laboratory high-temp furnaces are fully customizable to meet your unique heating rates and atmospheric needs.

Ready to optimize your densification process? Contact us today to find the perfect furnace solution and ensure the chemical purity of your next innovation.

Visual Guide

References

- Joel Arriaga‐Dávila, Arturo Susarrey‐Arce. From Single to Multi‐Glass/Ceramic Microarchitectures via Two‐Photon Lithography. DOI: 10.1002/adom.202501658

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is a muffle furnace and how is it related to laboratory furnaces? Discover Precision Heating for Your Lab

- How does a muffle furnace operate? Uncover Its Efficient, Contamination-Free Heating Process

- How does heat distribution in drying ovens compare to muffle furnaces? Discover Key Differences for Your Lab

- How does a laboratory high-temperature box furnace ensure the material performance of NN-10ST based ceramics?

- What features are included in the temperature control console of box furnaces? Achieve Precision and Repeatability in Thermal Processing

- What ensures heating uniformity in box type high-temperature resistance furnaces? Achieve Consistent Thermal Processing

- What are the recommended heating and cooling protocols for a muffle furnace? Ensure Longevity and Safety in Your Lab

- How does a laboratory box furnace contribute to the temperature program control for synthesizing PrVSb3 single crystals?