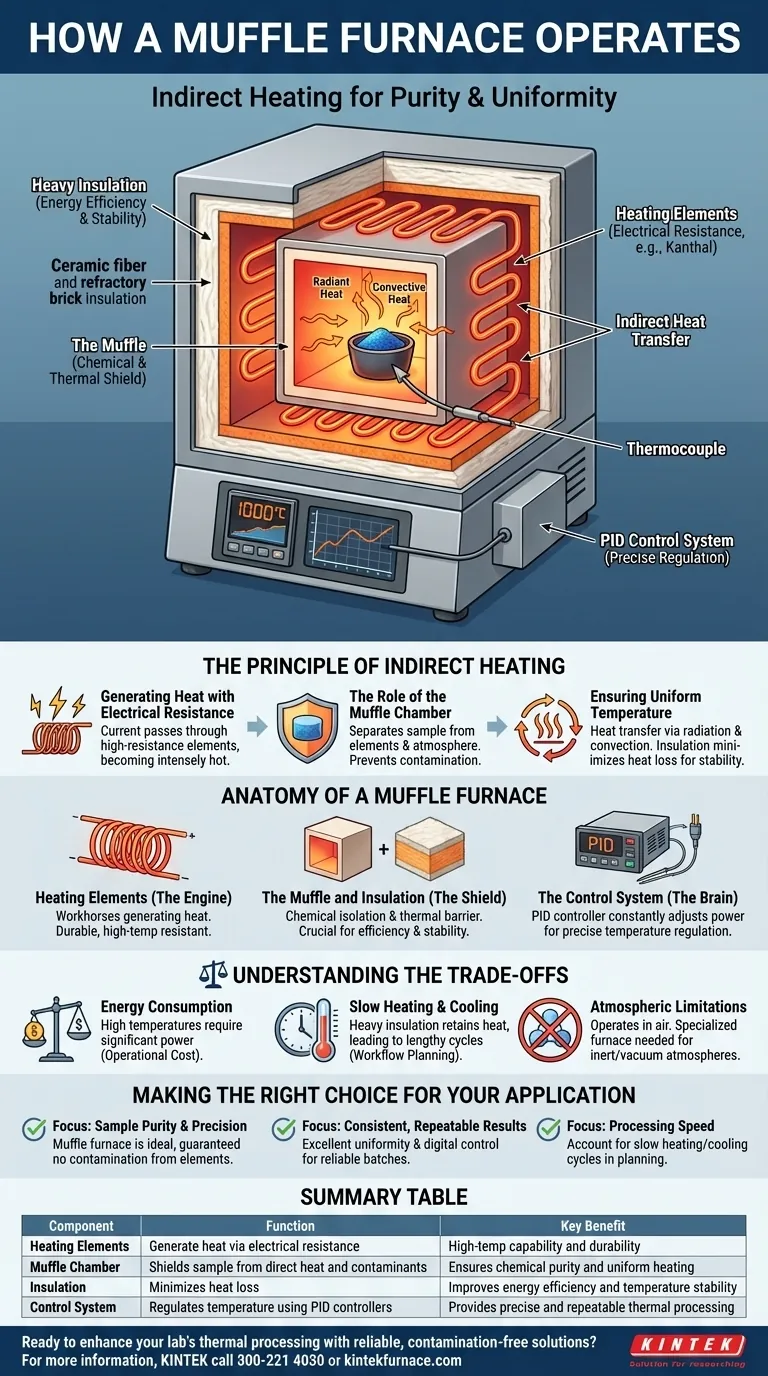

At its core, a muffle furnace operates by using electrical resistance heating elements to create a high-temperature environment inside an insulated chamber. This heat is then transferred indirectly to the material being processed, which is shielded within a protective enclosure—the "muffle"—ensuring uniform heating without any risk of contamination from the heat source itself.

The defining principle of a muffle furnace is not just heat generation, but controlled, indirect heating. The "muffle" chamber acts as a crucial barrier, separating the sample from the raw heating elements to provide a chemically pure and thermally uniform environment for processing.

The Principle of Indirect Heating

The operation of a muffle furnace is built around creating a pristine, high-heat environment. This is achieved by separating the heat source from the workload.

Generating Heat with Electrical Resistance

A muffle furnace converts electrical energy into thermal energy. A current is passed through heating elements, typically made of a high-resistance material like Kanthal or nichrome. As these elements resist the flow of electricity, they become intensely hot.

The Role of the Muffle Chamber

The heating elements do not directly touch the sample. Instead, they heat the space within a larger, insulated box. Inside this box is the muffle, a separate, sealed chamber made of a heat-resistant ceramic. The sample is placed inside this muffle.

This design prevents any particles from the heating elements or external atmosphere from contaminating the sample. It is the defining feature that differentiates a muffle furnace from simpler kilns or ovens.

Ensuring Uniform Temperature

Heat from the elements is transferred to the sample through radiation from the hot interior walls of the muffle and convection as the air inside the chamber heats up and circulates. The heavy insulation surrounding the entire apparatus minimizes heat loss, allowing the system to achieve a stable and evenly distributed temperature.

Anatomy of a Muffle Furnace

Understanding the function of each component clarifies how the furnace achieves its precise results.

Heating Elements (The Engine)

These are the workhorses of the furnace, responsible for generating all the heat. They are designed to withstand extremely high temperatures and repeated heating and cooling cycles.

The Muffle and Insulation (The Shield)

The muffle provides chemical isolation, while layers of dense ceramic fiber or refractory bricks provide thermal insulation. This insulation is critical for both energy efficiency and temperature stability, preventing heat from escaping into the lab.

The Control System (The Brain)

Modern muffle furnaces use a digital controller, often a PID (Proportional-Integral-Derivative) controller. This system constantly measures the chamber temperature with a thermocouple and precisely adjusts the power sent to the heating elements to maintain the set temperature with minimal fluctuation.

Understanding the Trade-offs

While highly effective, the design of a muffle furnace presents practical considerations you must account for.

Energy Consumption

Achieving and maintaining temperatures of 1000°C or higher requires a significant amount of electrical power. This is a primary operational cost.

Slow Heating and Cooling Rates

The same heavy insulation that makes the furnace so stable also means it retains heat for a long time. Both the heat-up and cool-down cycles can be lengthy, which must be factored into your workflow and scheduling.

Atmospheric Limitations

A standard muffle furnace operates in an air atmosphere. While it prevents contamination from the heat source, it does not control the processing atmosphere itself. For applications requiring an inert gas (like argon) or a vacuum, a specialized furnace with a sealed chamber and gas ports is necessary.

Making the Right Choice for Your Application

Understanding the furnace's operation helps you leverage its strengths for your specific goal.

- If your primary focus is sample purity and precision: A muffle furnace is the ideal choice, as its indirect heating method guarantees no contamination from the heating elements.

- If your primary focus is consistent, repeatable thermal processing: The excellent temperature uniformity and precise digital control of a muffle furnace will deliver reliable results batch after batch.

- If your primary focus is processing speed: Be prepared to account for the slow heating and cooling cycles inherent to a well-insulated furnace in your planning.

By understanding that a muffle furnace is designed for control and purity above all else, you can use it to achieve exceptionally reliable and clean high-temperature results.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Heating Elements | Generate heat via electrical resistance | High-temperature capability and durability |

| Muffle Chamber | Shields sample from direct heat and contaminants | Ensures chemical purity and uniform heating |

| Insulation | Minimizes heat loss | Improves energy efficiency and temperature stability |

| Control System | Regulates temperature using PID controllers | Provides precise and repeatable thermal processing |

Ready to enhance your lab's thermal processing with reliable, contamination-free solutions?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements.

Contact us today to discuss how our furnaces can deliver superior performance and efficiency for your specific applications!

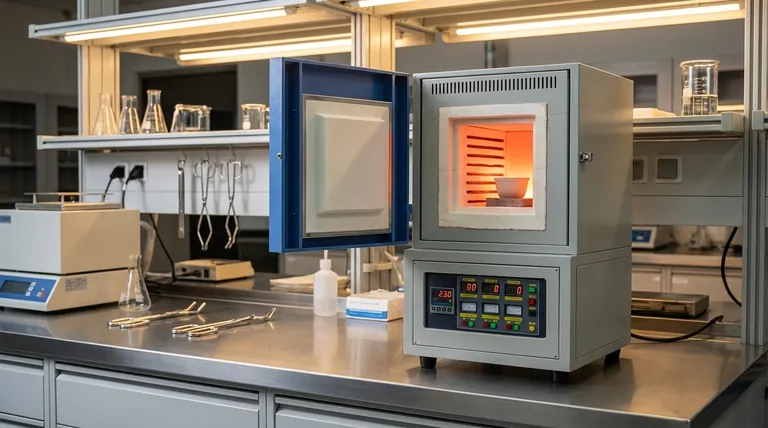

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis