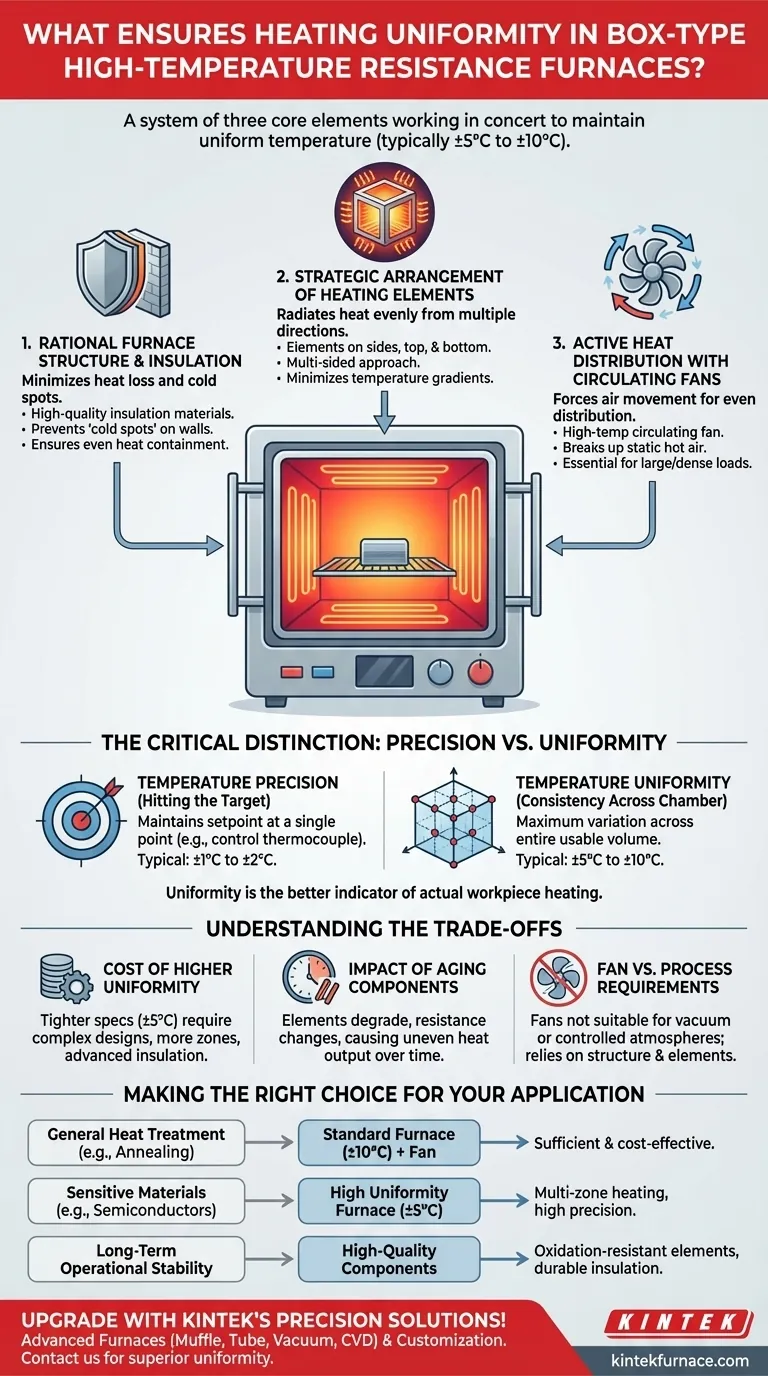

The heating uniformity in a box-type high-temperature resistance furnace is primarily ensured by a system of three core elements working in concert. These are a rationally designed furnace structure, the strategic arrangement of heating elements, and the use of mechanical devices like circulating fans to actively distribute heat. Together, these components typically maintain temperature uniformity within a range of ±5°C to ±10°C throughout the chamber.

Achieving true temperature uniformity is a systemic challenge that goes beyond simply reaching a setpoint. It is the result of a holistic design philosophy where the furnace's physical structure, the placement of its heat sources, and active air circulation are all optimized to eliminate hot and cold spots.

The Three Pillars of Heating Uniformity

To understand how a furnace achieves consistent temperature, we must look at how each core component contributes to the distribution of thermal energy.

Rational Furnace Structure and Insulation

The physical chamber is the foundation of uniformity. Its design directly impacts how heat is contained and reflected.

High-quality insulation materials are critical. They not only improve energy efficiency but also prevent the formation of "cold spots" on the furnace walls, ensuring that heat loss is minimal and even across all surfaces.

Strategic Arrangement of Heating Elements

Simply having powerful heating elements is not enough; their placement is paramount. The goal is to radiate heat evenly into the chamber from multiple directions.

Elements are typically distributed on the sides, top, and sometimes the bottom of the furnace. This multi-sided heating approach minimizes temperature gradients and ensures that the workpiece is heated uniformly from all angles, rather than from a single, intense source.

Active Heat Distribution with Circulating Fans

While radiation from elements does the primary work, natural convection is often insufficient to guarantee uniformity, especially in larger chambers or with densely packed loads.

A high-temperature circulating fan actively forces the atmosphere inside the furnace to move. This forced convection breaks up static layers of hot air, ensuring that heat is physically carried to every corner of the chamber and around the workpiece for more consistent results.

The Critical Distinction: Uniformity vs. Precision

A common point of confusion is the difference between temperature precision and temperature uniformity. They are not the same, and understanding this is crucial for selecting the right equipment.

Temperature Precision: Hitting the Target

Precision refers to how closely the furnace's control system can maintain the temperature at a single point, usually where the control thermocouple is located.

High-precision systems can often hold a setpoint to within ±1°C to ±2°C. This means the controller is very good at reading the sensor and adjusting power, but it says nothing about the temperature in other parts of the furnace.

Temperature Uniformity: Consistency Across the Chamber

Uniformity describes the maximum temperature variation across the entire usable volume of the furnace chamber. A typical specification is ±5°C to ±10°C.

This metric is a far better indicator of how evenly your workpiece will actually be heated. A furnace can have high precision but poor uniformity if it has hot and cold spots.

Understanding the Trade-offs

Achieving exceptional uniformity involves design choices that come with practical implications.

The Cost of Higher Uniformity

Tighter uniformity specifications (e.g., ±5°C or better) often require more complex and expensive designs. This may include more heating zones with independent controls, more advanced insulation, and more powerful fan systems.

The Impact of Aging Components

Over time, heating elements and insulation can degrade. As elements age, their resistance may change, causing them to output heat unevenly. This degradation is a primary cause of declining temperature uniformity over the furnace's service life, making the initial quality of these components a critical long-term factor.

Fan Circulation vs. Process Requirements

While fans are excellent for uniformity, they are not suitable for all processes. Vacuum or certain controlled atmosphere applications may prohibit the use of a fan. In these cases, uniformity relies entirely on the furnace's structural design and the strategic placement of its heating elements.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on the demands of your specific heat treatment process.

- If your primary focus is general heat treatment (e.g., annealing, tempering): A standard furnace with a specified uniformity of ±10°C and a circulating fan is typically sufficient and cost-effective.

- If your primary focus is processing sensitive materials (e.g., semiconductors, aerospace alloys): Prioritize furnaces with a certified high uniformity of ±5°C or better, likely featuring multi-zone heating and high-precision controls.

- If your primary focus is long-term operational stability: Invest in models that explicitly state the use of high-quality, oxidation-resistant heating elements and durable insulation to maintain performance for years.

Ultimately, understanding these core principles empowers you to look beyond simple specifications and select a furnace that delivers the consistent results your process demands.

Summary Table:

| Component | Role in Uniformity | Key Features |

|---|---|---|

| Furnace Structure & Insulation | Minimizes heat loss and cold spots | High-quality insulation, even heat reflection |

| Heating Elements | Radiates heat evenly from multiple sides | Strategic placement on sides, top, and bottom |

| Circulating Fans | Forces air movement for even distribution | Active convection to eliminate hot/cold spots |

| Overall System | Maintains temperature uniformity | Typically ±5°C to ±10°C across chamber |

Upgrade your lab's thermal processing with KINTEK's precision solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental needs are met with superior heating uniformity and long-term reliability. Contact us today to discuss how our furnaces can enhance your results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas