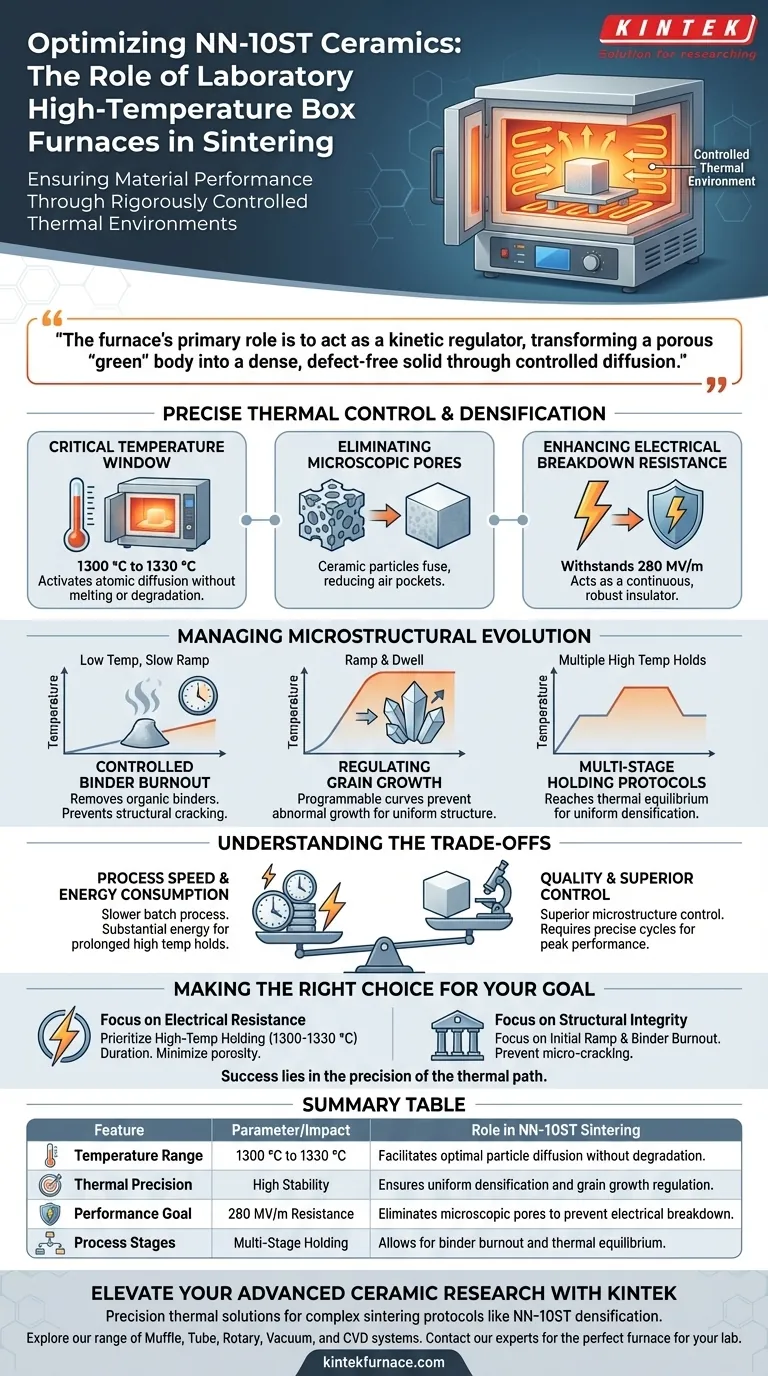

A laboratory high-temperature box furnace ensures material performance by providing a rigorously controlled thermal environment necessary for the densification of NN-10ST based ceramics. Specifically, it maintains a critical temperature range between 1300 °C and 1330 °C to facilitate particle diffusion. By executing precise temperature curves that include binder burnout and multiple holding stages, the furnace eliminates microscopic pores to achieve the high density required to withstand ultra-high electric fields of 280 MV/m.

The furnace’s primary role is to act as a kinetic regulator, transforming a porous "green" body into a dense, defect-free solid through controlled diffusion. This precise management of thermal energy is the direct cause of the ceramic's ability to resist extreme electrical breakdown.

Precise Thermal Control and Densification

The Critical Temperature Window

For NN-10ST ceramics, achieving optimal performance requires operating within a narrow thermal window of 1300 °C to 1330 °C.

The box furnace maintains this stability to ensure the thermal energy is sufficient to activate atomic diffusion without inducing melting or degradation.

Eliminating Microscopic Pores

The primary mechanism for performance gain is the elimination of porosity through densification.

As the furnace applies heat, ceramic particles fuse, reducing the volume of air pockets that would otherwise act as weak points.

Enhancing Electrical Breakdown Resistance

The direct result of this densification is the material's ability to withstand breakdown electric fields reaching 280 MV/m.

By removing voids, the furnace ensures the ceramic acts as a continuous, robust insulator rather than a porous structure susceptible to electrical failure.

Managing Microstructural Evolution

Controlled Binder Burnout

Before full sintering occurs, the furnace executes specific low-temperature phases to remove organic binders used in shaping the ceramic.

These phases prevent structural cracking or defects that would occur if gases were released violently under rapid heating.

Regulating Grain Growth

The furnace utilizes programmable heating curves to control the rate at which ceramic grains grow.

By managing this rate, the equipment prevents abnormal grain growth, ensuring the final microstructure is uniform and mechanically stable.

Multi-Stage Holding Protocols

Rather than a simple ramp-up and cool-down, the furnace employs multiple holding stages at specific temperatures.

These distinct dwell times allow the material to reach thermal equilibrium, ensuring that densification occurs uniformly throughout the entire ceramic body.

Understanding the Trade-offs

Process Speed vs. Quality

While a box furnace offers superior control over the microstructure, it is inherently a slower, batch-based process compared to techniques like microwave sintering.

The precise, multi-stage cycles required for NN-10ST ceramics can take significant time to execute properly.

Energy Consumption

Maintaing high temperatures (1300 °C+) for extended holding stages requires substantial energy input.

Operators must balance the need for perfect densification against the operational costs of prolonged sintering cycles.

Making the Right Choice for Your Goal

To maximize the performance of your NN-10ST ceramics, align your furnace programming with your specific material objectives:

- If your primary focus is Maximum Electrical Resistance: Prioritize the duration of the high-temperature holding stage (1300-1330 °C) to ensure absolute minimization of porosity.

- If your primary focus is Structural Integrity: Focus on the initial ramp rates and binder burnout phases to prevent micro-cracking before densification begins.

Success in sintering NN-10ST ceramics lies not just in reaching the target temperature, but in the precision of the thermal path you take to get there.

Summary Table:

| Feature | Parameter/Impact | Role in NN-10ST Sintering |

|---|---|---|

| Temperature Range | 1300 °C to 1330 °C | Facilitates optimal particle diffusion without degradation. |

| Thermal Precision | High Stability | Ensures uniform densification and grain growth regulation. |

| Performance Goal | 280 MV/m Resistance | Eliminates microscopic pores to prevent electrical breakdown. |

| Process Stages | Multi-Stage Holding | Allows for binder burnout and thermal equilibrium. |

Elevate Your Advanced Ceramic Research with KINTEK

Precision is the difference between material failure and achieving record-breaking electrical resistance. KINTEK provides the industry-leading thermal solutions required for complex sintering protocols like NN-10ST densification.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard lab high-temp furnaces or fully customizable systems tailored to your unique sintering curves, KINTEK ensures your materials reach their peak performance.

Ready to achieve superior material properties? Contact our experts today to find the perfect furnace for your laboratory.

Visual Guide

References

- Xinzhen Wang, Ian M. Reaney. Lead‐Free High Permittivity Quasi‐Linear Dielectrics for Giant Energy Storage Multilayer Ceramic Capacitors with Broad Temperature Stability. DOI: 10.1002/aenm.202400821

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What atmosphere control options are available in advanced muffle furnaces? Master Materials Processing with Precision

- What are the key considerations for temperature control in a Muffle furnace? Ensure Precision and Stability for Your Lab

- What is the purpose of a high-temperature muffle furnace for rare earth oxalate calcination? Achieve High-Purity REOs

- What temperature range is typical for furnace gas in a box type resistance furnace? Learn How to Choose the Right Furnace for Your Needs

- How does a high-temperature box furnace contribute to the sintering of doped zirconate ceramics? Achieve 94% Density

- How does a muffle furnace ensure precise temperature control? Discover the Key Components for Accurate Heating

- How does temperature control work in modern muffle furnaces? Achieve Unmatched Precision and Efficiency

- What is the maximum temperature of the muffle furnace? It's a critical design choice.