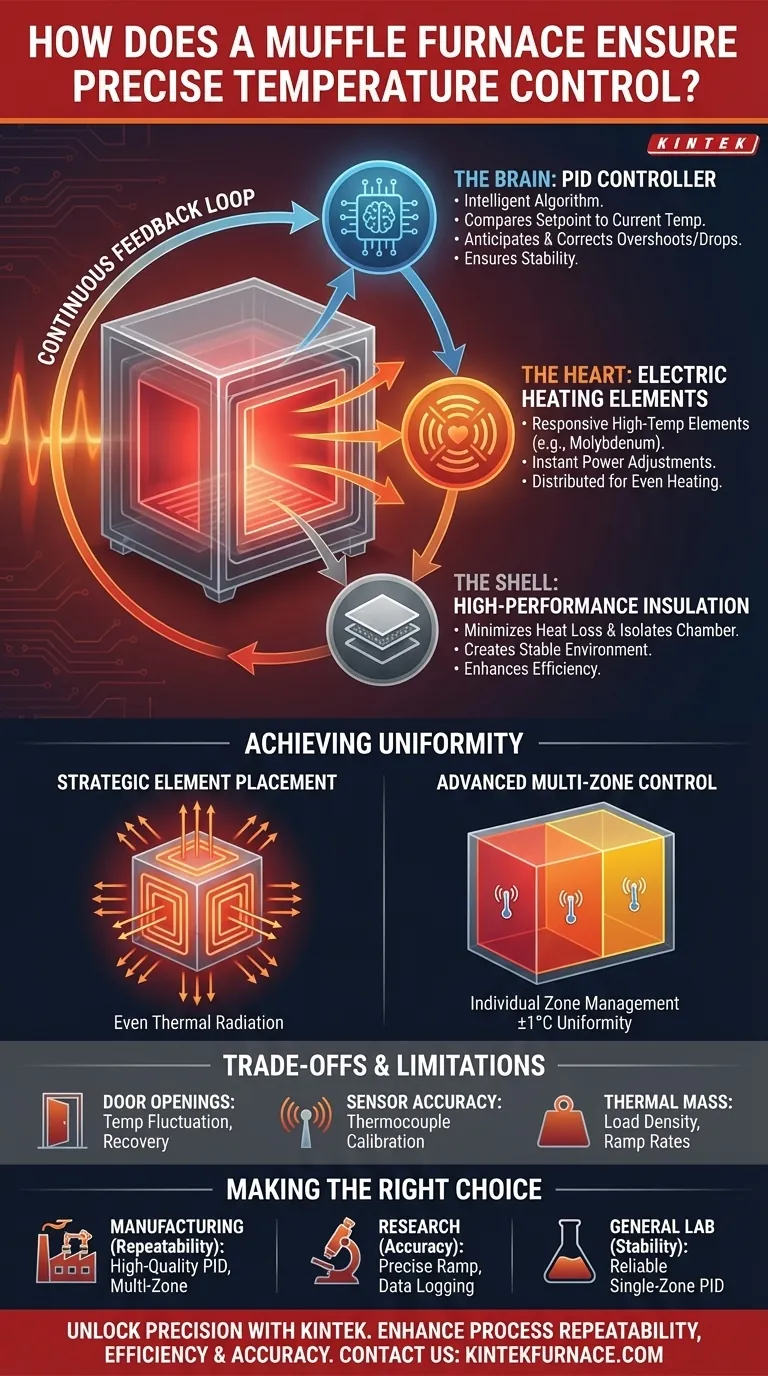

At its core, a muffle furnace achieves precise temperature control through the sophisticated interplay of three components: an intelligent digital controller, responsive electric heating elements, and highly effective thermal insulation. This system works in a continuous feedback loop to not only reach a set temperature but to hold it with remarkable stability, which is critical for sensitive material processing.

The precision of a muffle furnace isn't just about generating heat. It's about constant measurement and micro-adjustments, managed by a PID controller that acts like a highly responsive cruise control system for temperature.

The Three Pillars of Temperature Precision

The reliability of a muffle furnace hinges on a system where each component has a distinct and critical role. Understanding how they work together reveals why modern furnaces are so accurate.

The Brain: The PID Controller

A PID (Proportional-Integral-Derivative) controller is the central intelligence of the furnace. It is a sophisticated algorithm that ensures the temperature you set is the temperature you get.

Think of it like the cruise control in your car. It doesn't just turn the heat on or off. Instead, it continuously measures the current chamber temperature via a sensor (a thermocouple).

It then compares this reading to your setpoint and calculates the precise amount of power to send to the heating elements. The PID controller intelligently anticipates and corrects for temperature overshoots or drops, ensuring a smooth, stable thermal environment.

The Heart: Electric Heating Elements

Modern muffle furnaces use high-temperature electric heating elements instead of older, less precise combustion methods.

These elements, often made of materials like molybdenum or tungsten for high-temperature applications, can have their power output adjusted almost instantly. This responsiveness is what allows the PID controller's commands to be executed with such precision.

The placement of these elements around the chamber is also engineered to distribute heat evenly, minimizing hot and cold spots.

The Shell: High-Performance Insulation

Effective insulation is the final piece of the puzzle. It serves two main functions for temperature control.

First, it isolates the internal chamber from ambient temperature fluctuations, creating a stable environment for the controller to manage.

Second, it minimizes heat loss, which makes the entire system more efficient. Less heat escaping means the controller has to do less work to maintain the setpoint, leading to greater stability and lower power consumption.

Achieving Uniformity Across the Chamber

For many processes like sintering or brazing, it's not enough for the furnace to be at the right temperature; it must be the right temperature everywhere. This is known as thermal uniformity.

Strategic Element Placement

Furnace designers strategically place heating elements on multiple sides of the internal chamber. This multi-sided heating approach ensures that thermal energy radiates evenly towards the workpiece from all directions, which is essential for preventing warpage or inconsistent material properties.

Advanced Multi-Zone Control

High-end furnaces take this a step further with configurable heating zones. The chamber is divided into multiple sections, each with its own heating elements and temperature sensor.

Each zone is managed by the PID controller as a semi-independent area. This allows the system to achieve exceptional temperature uniformity, often as tight as ±1°C, even in large chambers or with complex workloads.

Understanding the Trade-offs and Limitations

While modern furnaces are incredibly precise, certain physical and operational factors can influence their performance.

The Impact of Door Openings

Opening the furnace door is the single largest cause of temperature fluctuation. A significant amount of heat is lost instantly, and the system must work hard to recover. A high-quality PID controller is designed to manage this recovery quickly and without significant temperature overshoot.

Sensor Accuracy and Placement

The furnace's reported temperature is only as accurate as its thermocouple. These sensors can degrade over time and may require periodic calibration or replacement to maintain the highest levels of accuracy. Their placement within the chamber is critical for providing a true representation of the environment.

Thermal Mass and Ramp Rates

The size of the furnace and the density of the material being heated (the thermal mass) create inertia. A large, dense load will naturally take longer to heat up and cool down. The control system manages this, but the maximum heating and cooling rates (ramp rates) are bound by these physical realities.

Making the Right Choice for Your Goal

Understanding these principles empowers you to select a furnace that aligns with the specific demands of your work.

- If your primary focus is process repeatability (e.g., manufacturing): Prioritize a furnace with a high-quality PID controller and multi-zone heating to ensure consistent results batch after batch.

- If your primary focus is material science research: Look for a system that offers precise ramp rate control, data logging capabilities, and the potential for calibration to ensure experimental accuracy.

- If your primary focus is general-purpose lab work (e.g., ashing, heat treating): A reliable single-zone furnace with a proven PID controller will provide the stability and precision required for most standard applications.

By understanding these core systems, you can operate your equipment with confidence, knowing exactly how it achieves the precision your work depends on.

Summary Table:

| Component | Role in Temperature Control | Key Features |

|---|---|---|

| PID Controller | Acts as the brain, continuously adjusting power to maintain set temperature | Uses algorithms to prevent overshoot, ensures stability |

| Electric Heating Elements | Serve as the heart, providing responsive heat output | Made of high-temp materials like molybdenum, allows instant power adjustments |

| High-Performance Insulation | Functions as the shell, minimizing heat loss and external fluctuations | Enhances efficiency and stability, isolates chamber from ambient changes |

| Multi-Zone Control | Achieves uniform temperature across the chamber | Divides chamber into zones with individual sensors, enables ±1°C uniformity |

Unlock Precision in Your Laboratory with KINTEK

Are you striving for flawless temperature control in your material processing, research, or manufacturing? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all designed with strong deep customization capabilities to meet your unique experimental requirements.

By choosing KINTEK, you'll benefit from:

- Enhanced process repeatability and accuracy for consistent results.

- Improved efficiency and stability in heat treatment applications.

- Customized solutions that address specific challenges in your lab.

Don't let temperature inconsistencies hold you back—contact us today to discuss how our furnaces can elevate your work and deliver the precision you deserve!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production