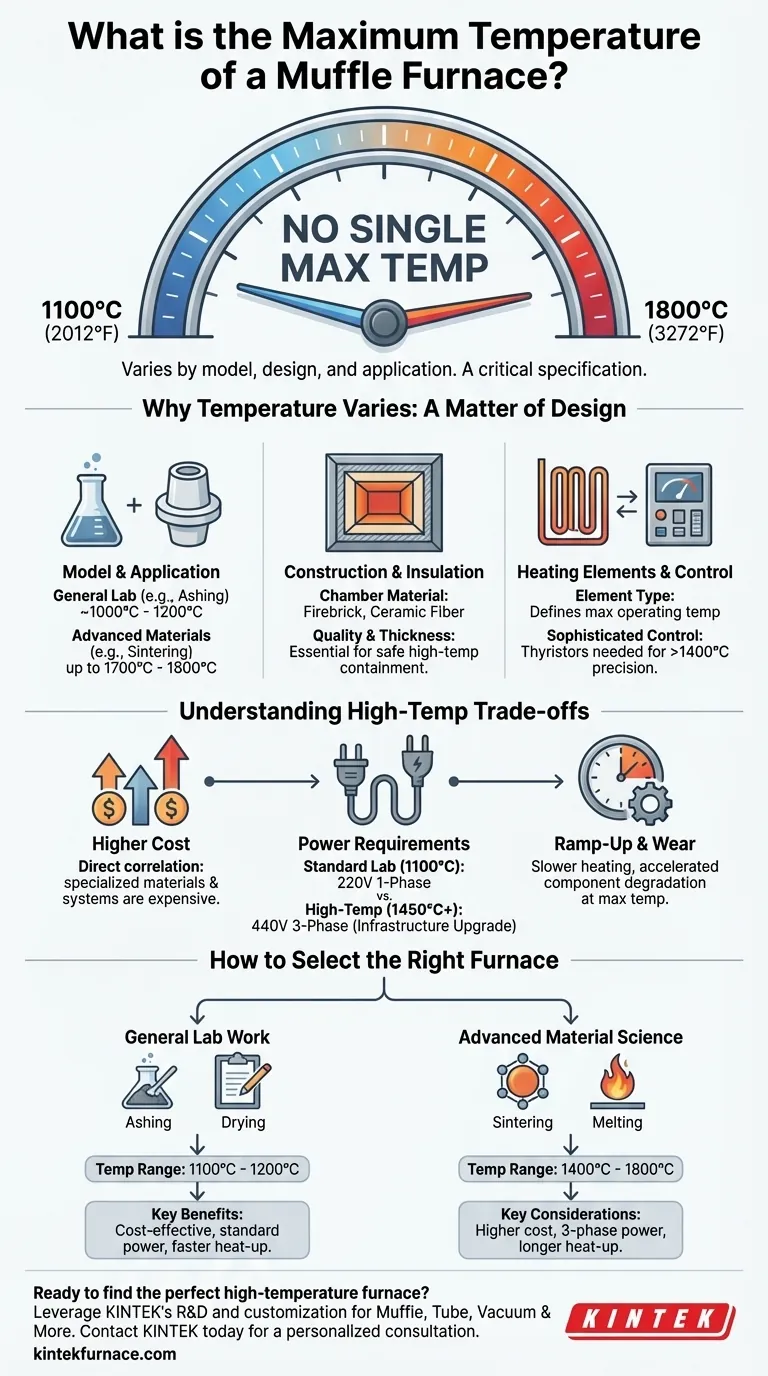

There is no single maximum temperature for a muffle furnace; it is a critical specification that varies significantly by model. While many standard laboratory units operate up to 1100°C or 1200°C, specialized furnaces are designed to reach temperatures as high as 1800°C (3272°F) for advanced material science applications.

The maximum temperature of a muffle furnace is not a fixed value but a design choice. It is determined by the furnace's construction, heating elements, and intended purpose, making it the most important factor to verify before purchase.

Why Temperature Varies: A Matter of Design

A muffle furnace is a category of high-temperature equipment, not a single standardized product. The maximum temperature is a direct result of its engineering and intended use case.

Model and Application

A furnace designed for general lab work like ashing organic compounds has different requirements than one built for sintering advanced ceramics. Laboratory models often provide a range of 1000°C to 1200°C, which covers a wide array of common processes.

Industrial or research-grade models are engineered for more extreme tasks, pushing the limits to 1700°C or 1800°C for melting metals or creating specialized materials.

Construction and Insulation

The furnace's ability to safely contain extreme heat depends on its internal chamber, or muffle. This chamber is typically made of highly refractory materials like firebrick or ceramic fiber.

The quality and thickness of this insulation are paramount. A furnace rated for 1800°C requires more advanced and expensive insulation and structural materials than a 1200°C model to operate safely and efficiently.

Heating Elements and Control

The components that generate the heat are a primary limiting factor. Different heating elements have different maximum operating temperatures.

Higher-performance furnaces also rely on more sophisticated power controllers, such as thyristors, to precisely manage the immense energy required to reach and maintain temperatures above 1400°C.

Understanding the Trade-offs of High-Temperature Models

Choosing a furnace with a higher maximum temperature involves significant trade-offs beyond its heating capability. These factors are critical for budget, facility planning, and operational efficiency.

Higher Temperature Means Higher Cost

There is a direct and steep correlation between maximum temperature and price. The specialized insulation, advanced heating elements, and robust power systems required for 1500°C+ operation are significantly more expensive than standard components.

Power and Infrastructure Requirements

A standard 1100°C lab furnace may run on a common 220V single-phase circuit. In contrast, a high-temperature model rated for 1450°C or more often requires a 440V three-phase power supply.

This is a major facility consideration that can involve significant electrical work and infrastructure upgrades.

Ramp-Up Time and Component Wear

While a small lab furnace might reach its target in 30-60 minutes, larger or higher-temperature models can take considerably longer. Furthermore, consistently operating any furnace at its absolute maximum temperature accelerates the degradation of heating elements and insulation, leading to more frequent maintenance and replacement.

How to Select the Right Furnace for Your Goal

Your final choice should be dictated by your specific process requirements, not just the pursuit of the highest possible temperature.

- If your primary focus is general laboratory work (e.g., ashing, drying, basic heat treating): A model with a maximum temperature around 1100°C to 1200°C is typically sufficient and more cost-effective.

- If your primary focus is advanced material science (e.g., sintering ceramics, melting alloys): You must seek out a specialized high-temperature furnace rated for 1400°C to 1800°C and verify your lab's power infrastructure can support it.

- If your primary focus is budget and efficiency: Select a furnace with a maximum temperature that provides a safe margin above your required operating temperature, as this will prolong its life and reduce energy costs.

Ultimately, choosing the right muffle furnace means matching the equipment's specifications to your precise technical needs.

Summary Table:

| Application Type | Typical Max Temperature Range | Key Considerations |

|---|---|---|

| General Laboratory Work (e.g., ashing, drying) | 1100°C - 1200°C | Cost-effective, standard power requirements, faster heat-up times. |

| Advanced Material Science (e.g., sintering, melting) | 1400°C - 1800°C | Higher cost, requires 3-phase power, longer heat-up times, increased maintenance. |

Ready to find the perfect high-temperature furnace for your application?

Navigating the trade-offs between temperature, cost, and infrastructure is complex. KINTEK simplifies this process. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by our strong deep customization capability to precisely meet your unique experimental requirements.

Let our experts help you select or custom-build a furnace that perfectly matches your technical needs and budget.

Contact KINTEK today for a personalized consultation

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination