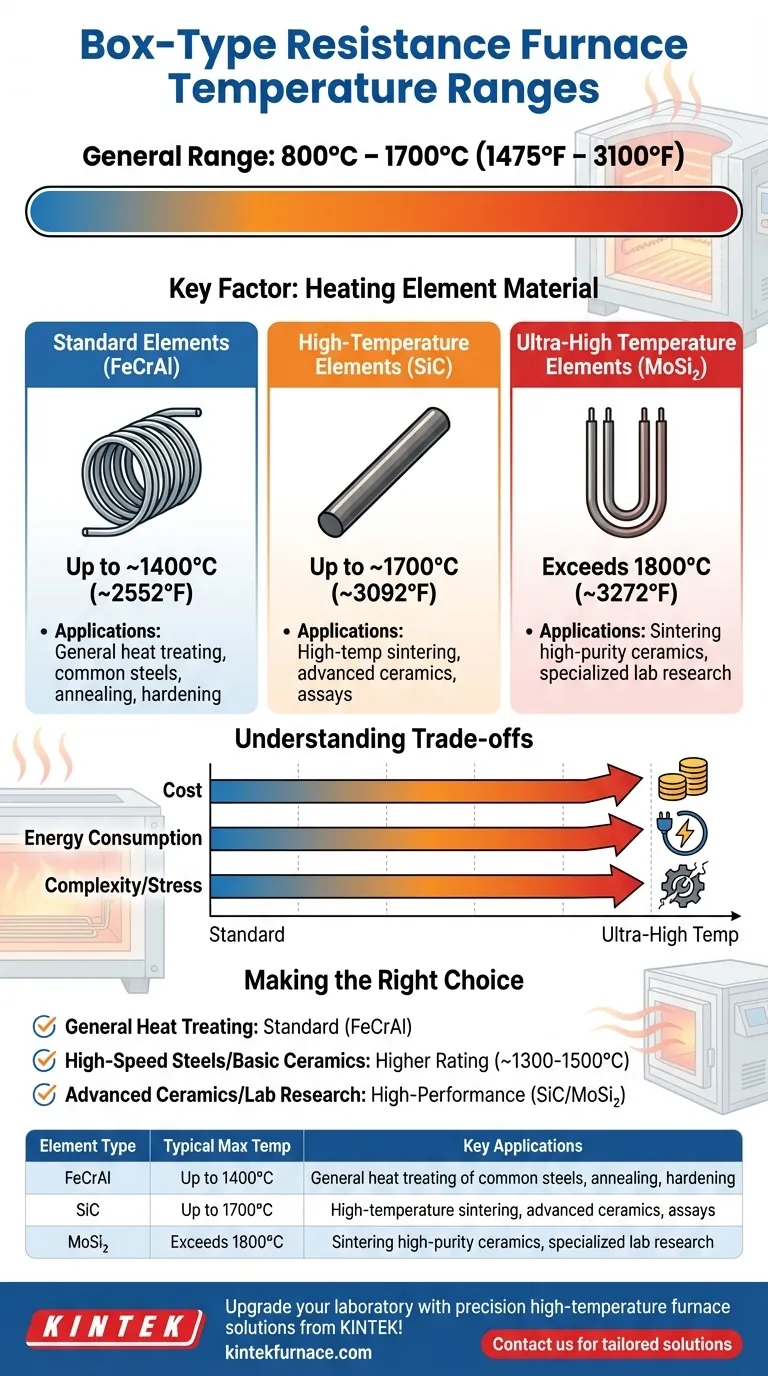

As a general rule, the temperature for furnace gas in a box-type resistance furnace typically ranges from 800°C to 1700°C (approximately 1475°F to 3100°F). This wide range exists because the maximum achievable temperature is not a single standard, but is dictated by the specific materials used in the furnace's construction—most importantly, the heating elements.

The maximum temperature of a box furnace is a direct function of its heating element technology. Standard furnaces using iron-chromium-aluminum alloys typically operate up to 1400°C, while specialized models with advanced elements like Silicon Carbide or Molybdenum Disilicide are required to reach 1700°C or higher.

What Dictates Furnace Temperature

The "box furnace" category covers a wide array of equipment. The key differentiator that determines the operating temperature range is the material used for the electrical resistance heating elements.

The Central Role of the Heating Element

Heating elements are the components that convert electrical energy into heat. Their chemical and physical properties place a hard limit on the furnace's maximum safe operating temperature.

Standard Elements (Up to ~1400°C)

Most common and cost-effective box furnaces use heating elements made from iron-chromium-aluminum (FeCrAl) alloys, often known by the trade name Kanthal.

These robust elements are ideal for a wide variety of heat-treating processes. Their typical maximum operating temperature is around 1300°C to 1400°C, aligning with the lower end of the overall temperature range.

High-Temperature Elements (Up to ~1700°C)

To achieve temperatures beyond the limits of FeCrAl, furnaces must use more advanced materials. The next tier commonly uses Silicon Carbide (SiC) heating elements.

These elements allow furnaces to reliably operate in the 1400°C to 1700°C range, making them necessary for high-temperature sintering, certain assays, and processing advanced materials.

Ultra-High Temperature Elements (>1700°C)

For the most demanding applications, such as sintering high-purity ceramics or specialized laboratory research, furnaces employ Molybdenum Disilicide (MoSi2) elements. These can operate at temperatures exceeding 1800°C.

Understanding the Trade-offs

Selecting a furnace based on temperature involves balancing capability with cost and operational complexity. A higher temperature rating is not always better.

Cost vs. Capability

There is a direct and significant price increase as you move up in temperature capability. A furnace with SiC elements capable of 1700°C will be substantially more expensive than a standard FeCrAl furnace that maxes out at 1300°C due to the cost of the elements and the required high-grade insulation.

Element Lifespan and Durability

Higher temperatures inherently put more stress on all furnace components. Advanced elements like SiC and MoSi2 are more brittle and less resistant to thermal shock than FeCrAl alloys. Their lifespan can be shorter, especially if process conditions are not carefully controlled.

Energy Consumption

The energy required to reach and maintain a setpoint temperature increases exponentially. Holding a furnace at 1600°C consumes far more power than holding it at 1100°C, leading to significantly higher operating costs.

Making the Right Choice for Your Goal

Base your decision on the specific requirements of your process, not on achieving the highest possible temperature.

- If your primary focus is general heat treating of common steels (annealing, hardening, tempering): A standard furnace with a maximum temperature between 1200°C and 1400°C is sufficient and the most cost-effective choice.

- If your primary focus is working with high-speed steels or basic ceramic processing: You will likely need a furnace with a higher rating, capable of reaching at least 1300°C to 1500°C.

- If your primary focus is sintering advanced ceramics or high-temperature lab research: You must invest in a high-performance furnace with SiC or MoSi2 elements designed to operate consistently at 1700°C or more.

Ultimately, matching the furnace's heating element technology to your specific application ensures you have the right capability without overinvesting in unnecessary capacity.

Summary Table:

| Heating Element Type | Typical Max Temperature | Key Applications |

|---|---|---|

| FeCrAl (Iron-Chromium-Aluminum) | Up to 1400°C | General heat treating of common steels, annealing, hardening |

| SiC (Silicon Carbide) | Up to 1700°C | High-temperature sintering, advanced ceramics, assays |

| MoSi2 (Molybdenum Disilicide) | Exceeds 1800°C | Sintering high-purity ceramics, specialized lab research |

Upgrade your laboratory with precision high-temperature furnace solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental requirements, enhancing efficiency and performance. Contact us today to discuss how our tailored furnace solutions can benefit your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab