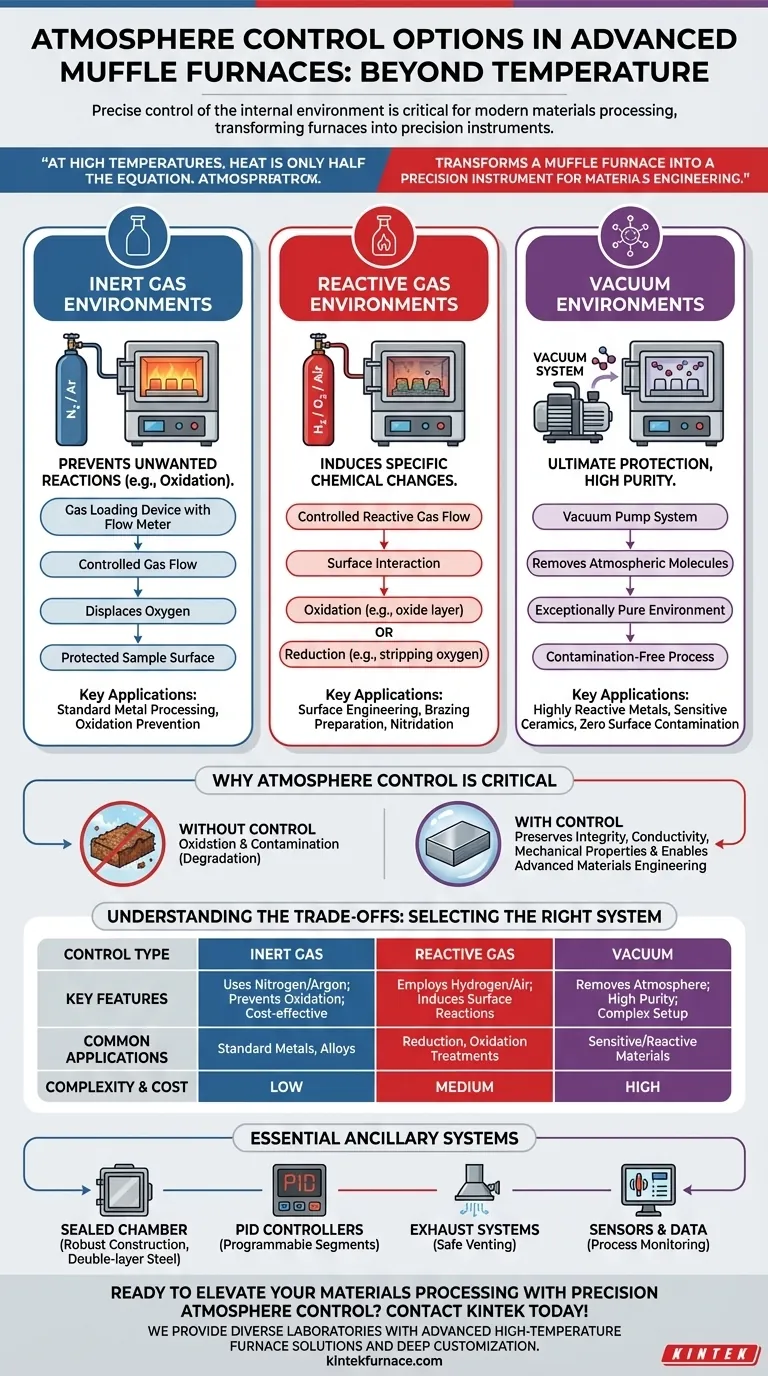

Advanced muffle furnaces offer precise control over the internal chemical environment, which is as critical as temperature for modern materials processing. The primary options available are adjustable gas systems, which introduce inert or reactive gases like nitrogen and hydrogen, and vacuum systems, which remove the atmosphere entirely. These technologies allow you to prevent unwanted reactions like oxidation or to intentionally induce specific chemical changes on a material's surface.

At high temperatures, heat is only half the equation. Atmosphere control is what transforms a muffle furnace from a simple oven into a precision instrument for materials engineering, giving you the power to dictate the final chemical and physical properties of your work.

The Core Mechanisms of Atmosphere Control

To understand which option is right for you, it's essential to grasp how each one works and what it's designed to achieve. The choice is not arbitrary; it's directly tied to your material and your desired outcome.

Inert Gas Environments

An inert gas atmosphere is the most common method for preventing unwanted chemical reactions, primarily oxidation. By purging the furnace chamber and flowing a non-reactive gas like nitrogen (N2) or argon (Ar), you displace the oxygen that would otherwise react with your material at high temperatures.

This process requires a gas delivery system, often including gas loading devices with flow meters, to ensure a consistent and controlled environment throughout the heating cycle.

Reactive Gas Environments

In some applications, the goal is not to prevent a reaction but to cause a specific one. Reactive gas systems enable this by introducing carefully controlled gases.

Common examples include flowing air or oxygen to create a uniform oxide layer (oxidation) or using hydrogen (H2) or a forming gas (a nitrogen/hydrogen mix) to strip oxygen from a material's surface (reduction). These processes are fundamental to altering surface properties for better performance.

Vacuum Environments

For the most sensitive materials, even the trace impurities in a high-purity inert gas can be problematic. A vacuum environment provides the ultimate protection by removing nearly all atmospheric molecules from the chamber.

Furnaces equipped with vacuum pump systems can achieve different levels of vacuum, creating an exceptionally pure environment. This is critical for processing highly reactive metals or for applications where any surface contamination would lead to failure.

Why Atmosphere Control is Critical

Controlling the atmosphere isn't an optional feature for advanced applications; it is a fundamental requirement for achieving repeatable, high-quality results.

Preventing Oxidation and Contamination

Most materials rapidly oxidize when heated in air. Atmosphere control directly prevents this degradation, preserving the material's integrity, conductivity, and mechanical properties.

Furthermore, a sealed, controlled atmosphere isolates the sample from combustion contaminants that can be present in simpler, directly-fired furnaces.

Engineering Specific Material Properties

Atmosphere control allows you to move beyond simple heating and into the realm of materials science. You can use it to intentionally create a protective oxide layer, prepare a surface for brazing by reducing existing oxides, or perform specialized treatments like nitridation.

This level of control is what enables the creation of advanced materials with tailored characteristics for aerospace, electronics, and medical applications.

Understanding the Trade-offs

Choosing the right system involves balancing capability, complexity, and cost. Each approach has distinct advantages and limitations.

Inert Gas vs. Vacuum

An inert gas system is generally simpler and more cost-effective to implement and operate. It is sufficient for most applications involving the prevention of oxidation in common metals and alloys.

A vacuum system offers a superior level of purity but is more complex and expensive. The requirement for robust seals and powerful pumps, along with longer cycle times for pumping down the chamber, makes it a specialized solution for highly sensitive materials.

The Importance of a Sealed Chamber

Effective atmosphere control is impossible without a well-sealed furnace. Advanced furnaces feature robust engineering, such as a double-layer steel structure and high-quality door seals, to prevent leaks that would compromise the internal environment.

Safety features, like an interlock that cuts power when the door opens, also play a role in maintaining a consistent and safe operating atmosphere.

Essential Ancillary Systems

Achieving precise atmospheric conditions relies on a suite of supporting components. PID controllers with programmable segments are essential for syncing temperature ramps with gas flow or vacuum levels.

Likewise, exhaust systems are needed to safely vent purged or reacted gases, while various sensors and output terminals provide data for process monitoring and quality control.

Selecting the Right Atmosphere for Your Application

The ideal atmosphere control strategy depends entirely on your material and desired outcome.

- If your primary focus is preventing oxidation on standard metals: An inert nitrogen (N2) atmosphere is often the most cost-effective and practical solution.

- If your primary focus is processing highly reactive or sensitive materials (e.g., titanium, certain ceramics): A vacuum system provides the highest level of purity and protection.

- If your primary focus is intentionally altering the surface chemistry (e.g., reduction or creating an oxide layer): A reactive gas system with precise flow control for gases like hydrogen or air is necessary.

By matching the furnace's atmospheric capabilities to your specific process goals, you gain direct control over the final properties and quality of your materials.

Summary Table:

| Control Type | Key Features | Common Applications |

|---|---|---|

| Inert Gas | Uses nitrogen or argon; prevents oxidation; cost-effective | Standard metal processing, oxidation prevention |

| Reactive Gas | Employs hydrogen or air; induces surface reactions | Reduction, oxidation treatments, surface engineering |

| Vacuum | Removes atmosphere; high purity; complex setup | Sensitive materials, reactive metals, contamination-free processes |

Ready to elevate your materials processing with precision atmosphere control? Contact KINTEK today to discuss your specific needs! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements. Get in touch now for expert guidance and tailored solutions!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the significance of using a muffle furnace to determine the ash content of biochar? Master Material Performance

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- How does a laboratory high-temperature box furnace assist in evaluating concrete fire resistance? | KINTEK

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure