In a dental laboratory, a muffle furnace is the essential high-temperature oven used to transform raw materials into finished, high-strength dental restorations. It is the critical tool for processes like sintering zirconia, firing porcelain, and burning out wax patterns for casting crowns, bridges, and veneers, ensuring they have the required durability and aesthetic appearance.

The furnace's core value is its ability to provide a precisely controlled, uniform, and contaminant-free heating environment. This is not just a feature; it is the fundamental requirement for processing the advanced ceramics and alloys that define modern restorative dentistry.

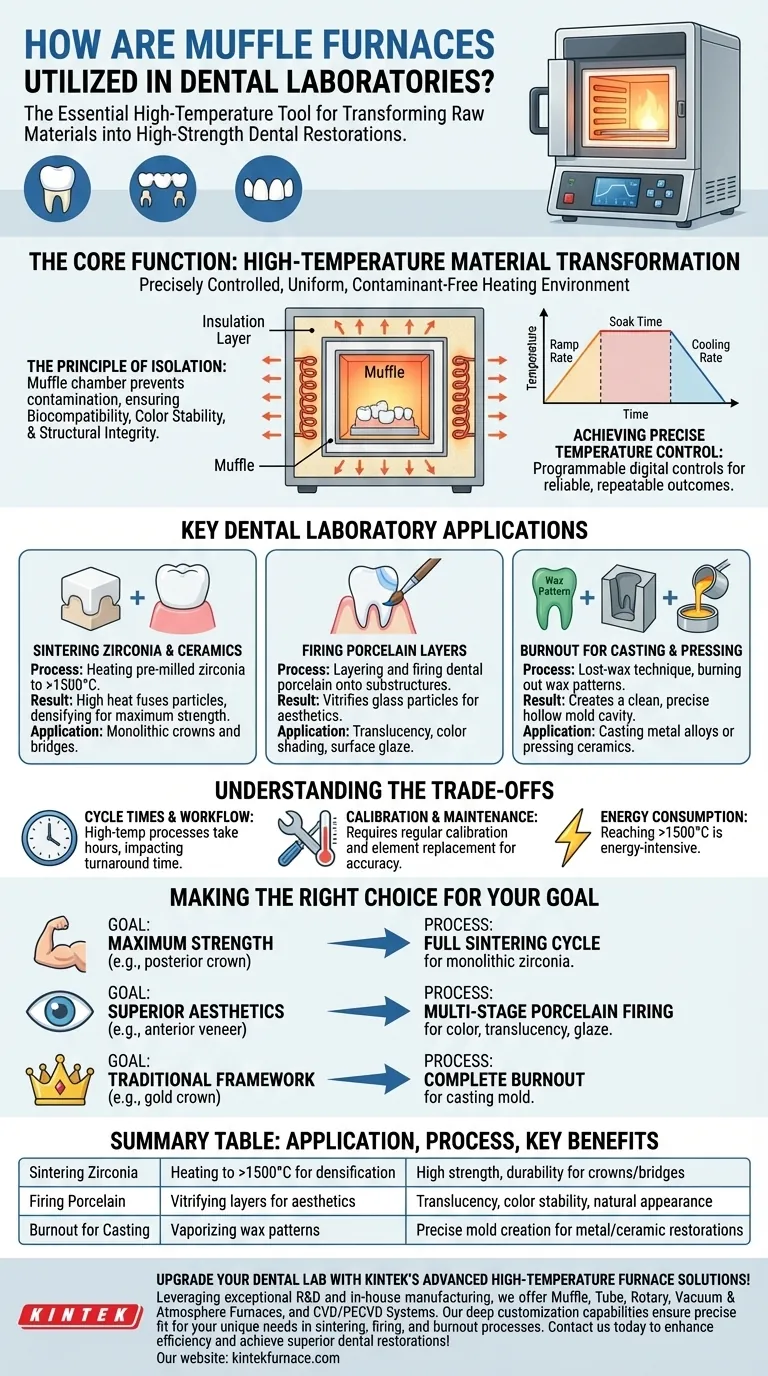

The Core Function: High-Temperature Material Transformation

A muffle furnace is a specialized, compact oven designed for precise high-temperature applications. Its defining feature is the "muffle," an inner chamber that isolates the material being heated from the actual heating elements.

The Principle of Isolation

The muffle chamber acts as a barrier. This prevents any byproducts of combustion or contaminants from the heating elements from coming into contact with the sensitive dental materials.

This separation is critical for ensuring the biocompatibility, color stability, and structural integrity of the final dental restoration.

Achieving Precise Temperature Control

Dental materials require very specific heating and cooling cycles. A few degrees of deviation can ruin the material's properties.

Muffle furnaces offer programmable digital controls that manage the rate of temperature increase (ramp rate), the time spent at maximum temperature (soak time), and the cooling rate. This precision is what makes outcomes reliable and repeatable.

Key Dental Laboratory Applications

Different dental restorations require distinct furnace processes. The furnace's versatility allows a single lab to perform a wide range of tasks.

Sintering Zirconia and Ceramics

Sintering is the primary method for creating monolithic zirconia crowns and bridges. In this process, a pre-milled, chalky zirconia part is heated to temperatures often exceeding 1500°C.

This high heat fuses the ceramic particles together, causing the material to shrink and densify into an incredibly strong, solid structure suitable for handling chewing forces.

Firing Porcelain Layers

To achieve a natural tooth-like appearance, technicians stack layers of dental porcelain onto a zirconia or metal substructure. Each layer is fired in the furnace to vitrify the glass particles.

This carefully controlled firing creates the translucency, color shading, and surface glaze that mimic a real tooth.

Burnout for Casting and Pressing

In the "lost-wax technique," a wax model of a crown or bridge framework is created and encased in a plaster-like investment material.

The furnace is used to burn out the wax, melting and vaporizing it completely. This leaves a hollow mold cavity into which molten metal alloy is cast or hot ceramic is pressed, perfectly replicating the original wax shape.

Understanding the Trade-offs

While indispensable, muffle furnaces come with operational considerations that labs must manage.

Cycle Times and Workflow

High-temperature processes are not instantaneous. A full sintering cycle for zirconia, for example, can take several hours from start to finish.

This processing time is a major factor in a dental lab's daily workflow and overall turnaround time for a case.

Calibration and Maintenance

To ensure consistent and accurate results, the furnace's temperature must be regularly calibrated. Any drift can lead to weak or poorly fitting restorations.

Heating elements also degrade over time and require eventual replacement, representing an ongoing operational cost.

Energy Consumption

Reaching and maintaining temperatures of 1500°C or higher requires a significant amount of electrical energy. This makes the furnace one of the more energy-intensive pieces of equipment in the lab.

Making the Right Choice for Your Goal

The furnace's program is selected based on the specific material and the desired final outcome.

- If your primary focus is maximum strength for a posterior crown or bridge: The key process is a full sintering cycle for a monolithic zirconia restoration.

- If your primary focus is superior aesthetics for an anterior veneer: The key is a multi-stage porcelain firing process to build up color, translucency, and a natural glaze.

- If your primary focus is creating a traditional gold crown or metal framework: The key process is a complete burnout of the wax pattern to create a clean, precise mold for casting.

Ultimately, the muffle furnace is the cornerstone of the modern dental lab, enabling technicians to reliably craft durable and lifelike dental restorations from advanced materials.

Summary Table:

| Application | Process | Key Benefits |

|---|---|---|

| Sintering Zirconia | Heating to >1500°C for densification | High strength, durability for crowns/bridges |

| Firing Porcelain | Vitrifying layers for aesthetics | Translucency, color stability, natural appearance |

| Burnout for Casting | Vaporizing wax patterns | Precise mold creation for metal/ceramic restorations |

Upgrade your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise fit for your unique needs in sintering, firing, and burnout processes. Contact us today to enhance efficiency and achieve superior dental restorations!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

People Also Ask

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis