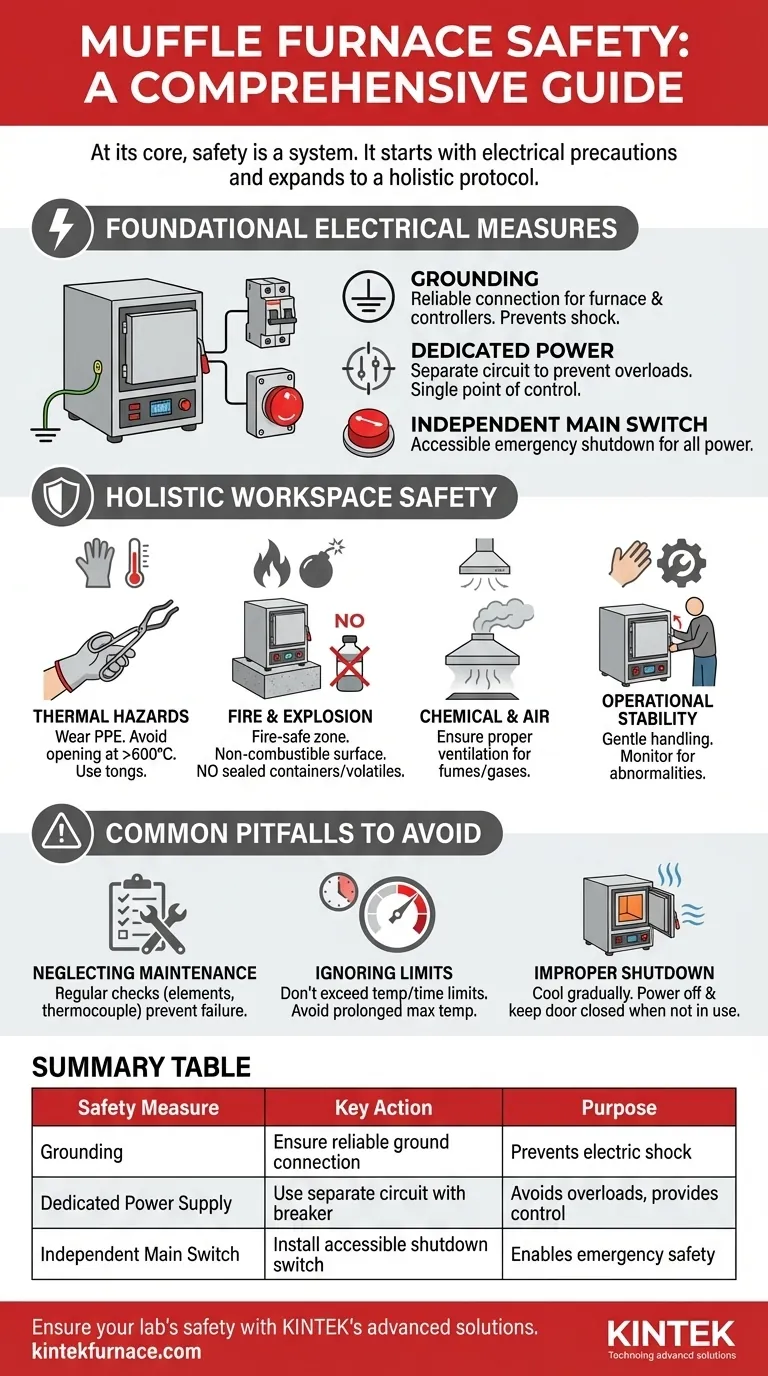

At its core, ensuring electrical safety for a muffle furnace involves three critical actions: guaranteeing a reliable ground connection, isolating the furnace on a dedicated power circuit with its own switch, and installing a separate, accessible main power switch to cut all electricity in an emergency. These steps are the foundation for preventing electric shock and electrical fires.

While electrical precautions are the first line of defense, true safety is a comprehensive system. It requires treating the furnace not just as an electrical device, but as a source of extreme heat and potential chemical hazards that demands a holistic approach to a safe workspace and operator protocol.

Foundational Electrical Safety Measures

A muffle furnace is a high-power device, and treating its electrical supply casually is a significant risk. The following measures are non-negotiable for safe installation and operation.

The Critical Role of Grounding

Proper grounding is your most important defense against electric shock. It provides a safe path for electrical current to flow to the earth in the event of a fault, preventing the furnace's metal casing from becoming dangerously energized.

Both the furnace itself and any external temperature controllers must be reliably and independently grounded. Never operate a furnace without confirming the integrity of its ground connection.

Implementing a Dedicated Power Supply

A muffle furnace should always be powered through a dedicated circuit with its own "electric gate" or circuit breaker. This is crucial for two reasons.

First, it prevents you from overloading a shared circuit, which can lead to tripped breakers or, in a worst-case scenario, an electrical fire. Second, it gives you a clear, single point of control to de-energize the furnace.

Installing an Independent Main Switch

For maximum safety, an additional, clearly labeled power switch should be installed at the power line's inlet. This switch serves as the main power control for the entire furnace system.

This setup ensures that you can completely and immediately cut off the main power supply without having to access a distant circuit breaker panel in an emergency.

Expanding Safety Beyond Electrical Concerns

Electrical safety is just one piece of the puzzle. The extreme temperatures generated by a muffle furnace introduce significant thermal, chemical, and operational hazards that must be managed proactively.

Preventing Thermal Hazards and Burns

The most common injuries from muffle furnaces are severe burns. Always wear appropriate personal protective equipment (PPE), including heat-resistant gloves and safety goggles.

Never open the furnace door when the internal temperature is above 600°C. Even after a cycle is complete, handle samples with tongs and extreme care.

Mitigating Fire and Explosion Risks

The area around the furnace must be a dedicated, fire-safe zone. Place the unit on a stable, non-combustible surface like a cement platform, and keep the workspace completely free of flammable or explosive materials.

Never place sealed containers, liquids, or volatile substances inside the furnace. Rapid heating can cause extreme pressure buildup, leading to sample rupture or an explosion that can destroy the furnace and endanger operators.

Managing Chemical and Atmospheric Hazards

Many processes conducted in a muffle furnace can release fumes or gases. Ensure the laboratory or workspace has proper, functioning ventilation to safely exhaust any potential byproducts.

Ensuring Physical and Operational Stability

The furnace must be handled with care. Close the furnace door gently to avoid damaging the refractory materials and heating elements.

During operation, monitor temperature changes closely. If you observe any abnormal fluctuations or sounds, cut the power immediately and investigate the cause once the unit has cooled.

Common Pitfalls and Procedural Errors to Avoid

Even with a perfect setup, human error and procedural neglect can undermine safety. Avoiding these common mistakes is essential for long-term safe operation.

Overlooking Routine Maintenance

Safety is not a one-time setup. Regularly perform maintenance checks on the heating elements, thermocouple, and the integrity of the furnace chamber. A degrading element can lead to electrical failure.

Ignoring Temperature and Time Limits

Do not exceed the furnace's maximum specified temperature. Likewise, avoid operating the furnace at its rated maximum temperature for excessively long periods, as this puts undue stress on all components and shortens its operational life.

Improper Shutdown and Cooling

After a cycle, always turn off the power and remove your samples. Then, open the furnace door just slightly to allow it to cool down gradually. When not in use for extended periods, cut all power and keep the door closed to protect the delicate refractory materials from atmospheric moisture.

Implementing a Robust Safety Protocol

Your approach to safety should be tailored to the primary risks of your application. Use these guidelines to structure your lab's standard operating procedures.

- If your primary focus is preventing electric shock: Prioritize proper grounding and a dedicated, easily accessible power cutoff switch above all else.

- If your primary focus is preventing fires or explosions: Ensure the workspace is completely clear of flammables and never introduce volatile, sealed, or unknown materials into the furnace.

- If your primary focus is operator safety and equipment longevity: Combine all electrical precautions with strict adherence to operating procedures, including PPE, temperature limits, and routine maintenance checks.

Ultimately, a safe laboratory is the result of a continuous, proactive commitment to established procedures and a deep respect for the equipment's potential hazards.

Summary Table:

| Safety Measure | Key Action | Purpose |

|---|---|---|

| Grounding | Ensure reliable ground connection for furnace and controllers | Prevents electric shock by safely diverting fault current |

| Dedicated Power Supply | Use a separate circuit with its own breaker | Avoids overloads and provides clear power control |

| Independent Main Switch | Install accessible switch to cut all power | Enables emergency shutdown for immediate safety |

Ensure your lab's safety with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, enhancing efficiency and reducing risks. Don't compromise on safety—contact us today to discuss how we can support your specific requirements!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control