The primary function of an industrial-grade burnout furnace is to thermally decompose insulating resin films before the smelting process begins. By heating enameled copper wire scrap to approximately 300°C, the furnace effectively carbonizes organic coatings such as polyurethane or polyesterimide, preventing them from becoming contaminants later in the refining line.

The presence of organic insulation during high-temperature smelting creates residues that compromise the integrity of liquid copper. Pre-treatment via a burnout furnace is the definitive method to isolate these contaminants early, ensuring significantly higher purity in the final refined copper.

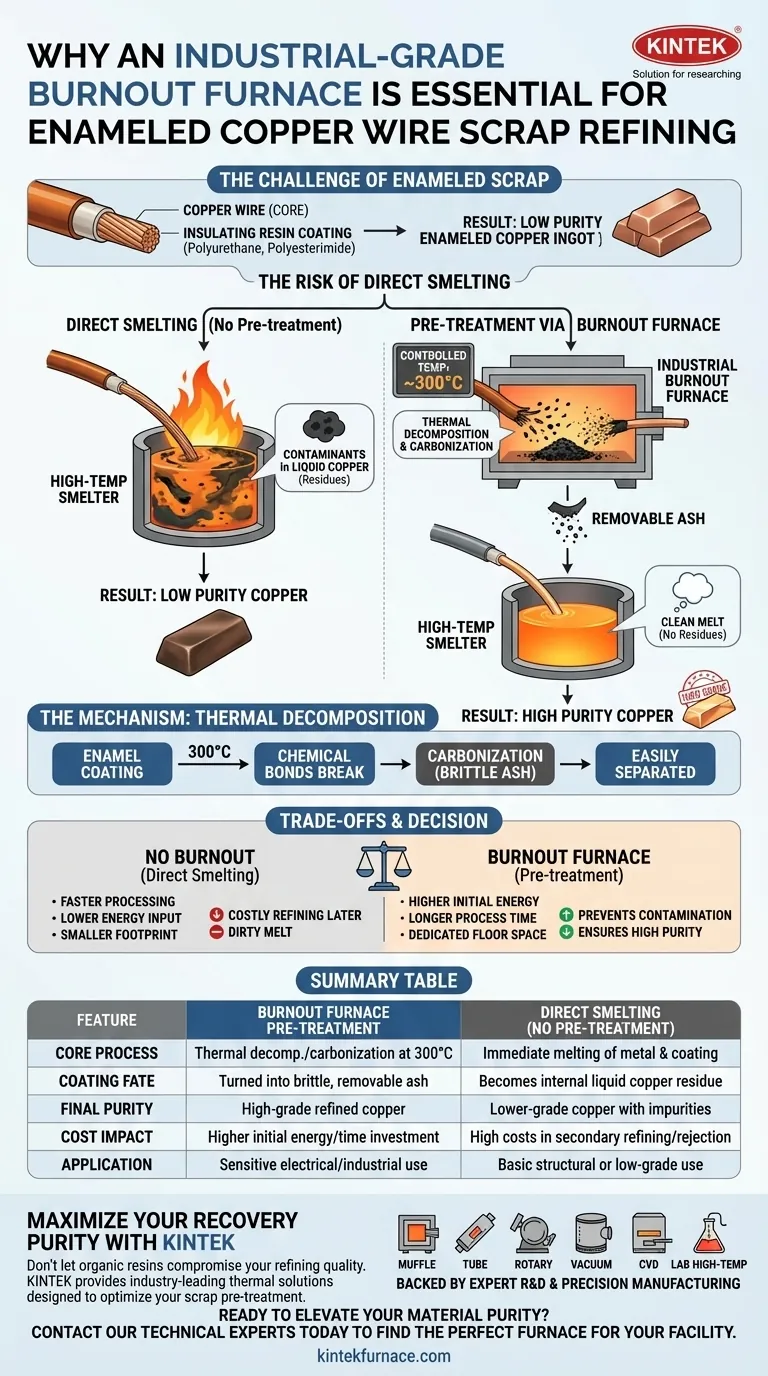

The Challenge of Enameled Scrap

Understanding the Coating

Enameled copper wire is not bare metal; it is coated with durable insulating resin films.

Common materials include polyurethane and polyesterimide. While excellent for electrical insulation, these organic compounds act as impurities during the recycling process.

The Risk of Direct Smelting

If enameled wire is introduced directly into a high-temperature smelting environment, the coatings do not simply disappear.

Instead, they break down into complex residues. These residues mix with the copper liquid, leading to internal contamination that is difficult and expensive to remove once the metal is molten.

The Mechanism of Thermal Decomposition

Controlled Temperature

The burnout furnace operates at a specific, controlled temperature of roughly 300°C.

This temperature is critical. It is hot enough to break down the chemical bonds of the resin, but cool enough to avoid prematurely melting or oxidizing the copper wire itself.

Carbonization

At this temperature, the furnace triggers a process of decomposition and carbonization.

The insulating films lose their structural integrity and turn into brittle carbonized ash. This transforms a complex chemical contaminant into a simple byproduct that is easily separated from the metal.

Understanding the Trade-offs

Process Time and Energy

Implementing a burnout stage adds a distinct step to the refining workflow.

This requires additional energy input to maintain the 300°C environment and increases the total time required to process a batch of scrap.

Equipment Footprint

An industrial-grade furnace requires dedicated floor space and maintenance.

However, skipping this step to save space or time results in a "dirty" melt, which often necessitates more aggressive (and costly) refining techniques later to correct the purity levels.

Making the Right Choice for Your Goal

Deciding whether to implement a burnout furnace depends on your quality requirements.

- If your primary focus is High Purity: You must use a burnout furnace to strip organic resins, as this is the only way to prevent residue contamination in the melt.

- If your primary focus is Processing Speed: You might consider skipping pre-treatment, but be aware that the resulting copper will be lower grade and likely unsuitable for sensitive electrical applications.

By isolating the organic contaminants before the copper ever reaches its melting point, you protect the integrity of your final product.

Summary Table:

| Feature | Burnout Furnace Pre-treatment | Direct Smelting (No Pre-treatment) |

|---|---|---|

| Core Process | Thermal decomposition/carbonization at 300°C | Immediate melting of metal and coating |

| Coating Fate | Turned into brittle, removable ash | Becomes internal liquid copper residue |

| Final Purity | High-grade refined copper | Lower-grade copper with impurities |

| Cost Impact | Higher initial energy/time investment | High costs in secondary refining/rejection |

| Application | Sensitive electrical/industrial use | Basic structural or low-grade use |

Maximize Your Recovery Purity with KINTEK

Don't let organic resins compromise your refining quality. KINTEK provides industry-leading thermal solutions designed to optimize your scrap pre-treatment. Backed by expert R&D and precision manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your specific refining requirements.

Ready to elevate your material purity? Contact our technical experts today to find the perfect furnace for your facility.

Visual Guide

References

- Omar Choukri, Souadi Taibi. Achieving industrial-grade purity in recycled copper scrap: Pretreatment and fire refining approach. DOI: 10.46793/tribomat.2025.008

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the purpose of the muffle furnace sintering process for manganese oxide substrates? Achieve Industrial Strength

- What are the key advantages of using a muffle furnace? Achieve Precise, Contamination-Free Heating for Your Lab

- Why is a muffle furnace utilized for Boehmite treatment? Optimize Your Catalyst Preparation

- What are the standard features of box furnaces? Unlock Precision and Efficiency in Thermal Processing

- How does the calcination process in a precision muffle furnace affect CuO nanoparticles? Optimize Your Synthesis.

- What are the latest technological advancements in muffle furnaces? Discover Precision, Efficiency, and Control Innovations

- What are the advantages of using a laboratory infrared heating furnace for PET waste conversion? Boost Energy Efficiency

- What emergency preparedness measures should be taken when using a muffle furnace? Ensure Safety and Prevent Hazards