The most critical emergency preparedness measures for a muffle furnace involve ensuring proper electrical grounding, maintaining a clear zone free of flammable materials, and having a suitable fire extinguisher immediately accessible. Operators must be trained not only on fire response but also on the specific operational risks of the furnace, including thermal shock and electrical faults.

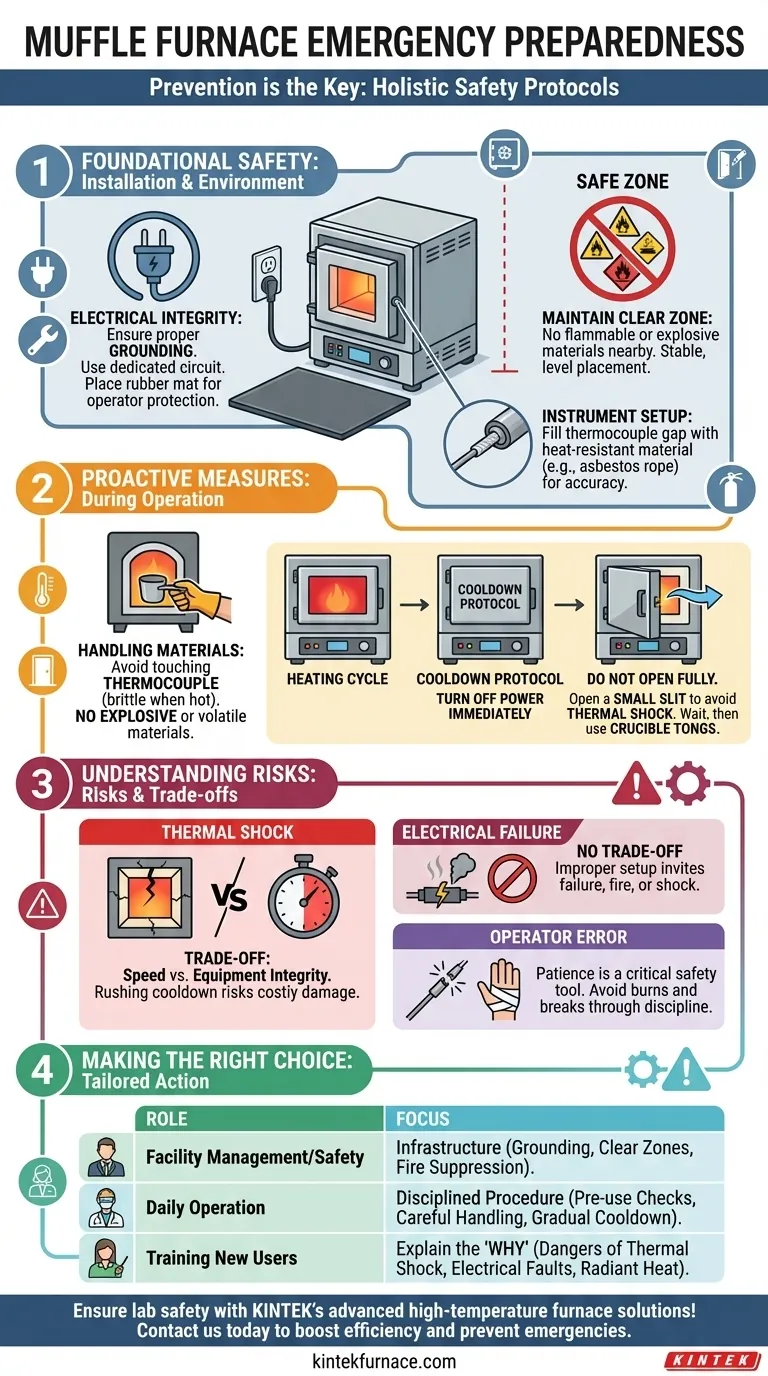

True preparedness for a muffle furnace is not about reacting to an emergency, but preventing one. It requires a holistic safety protocol that covers everything from initial electrical setup and environmental controls to disciplined operational procedures during heating and cooling cycles.

Foundational Safety: Installation and Environment

The first line of defense against an emergency is a correct and secure installation. Flaws in the setup introduce risks before the furnace is ever turned on.

Ensuring Electrical Integrity

A muffle furnace is a high-power device, and electrical safety is paramount. The furnace shell and its controller must be connected to a ground wire to prevent the risk of severe electric shock.

The unit should be powered through a dedicated circuit with plugs, sockets, and fuses that match its specified voltage and current ratings. Using a dedicated electric gate or switch allows you to control the main power supply decisively.

For added operator protection, a thick rubber insulating mat should be placed on the floor in front of the furnace. This provides a barrier between the operator and the ground, reducing the path for current in the event of an electrical fault.

Establishing a Safe Zone

The furnace must be placed on solid, level ground away from any foot traffic. This ensures stability and prevents accidental contact.

Crucially, no flammable or explosive materials should be stored anywhere near the furnace. The extreme heat radiated from the unit can easily ignite nearby combustibles, creating a significant fire hazard.

Proper Instrument Setup

The thermocouple, which measures the internal temperature, is a sensitive component. It should be inserted carefully into the center of the furnace chamber.

The gap between the thermocouple and the furnace wall must be filled with a heat-resistant material like asbestos rope. This prevents heat loss and ensures accurate temperature readings, which is critical for process control and safety.

Proactive Measures During Operation

Safe operation is an active process. Preventing accidents requires constant vigilance and adherence to proven procedures.

Handling Materials Safely

When loading or unloading the furnace, you must avoid touching the thermocouple. At high temperatures, it becomes extremely brittle and can easily break upon contact, leading to a loss of temperature control.

Never place explosive, volatile, or dangerously reactive materials inside the furnace. The contained high-temperature environment can cause a violent reaction or explosion.

The Critical Cooldown Protocol

After a heating cycle is complete, turn off the power supply immediately. However, do not open the furnace door right away.

Opening the door fully will cause a sudden rush of cool air, creating thermal shock. This rapid temperature change can cause the internal furnace chamber, which is often made of ceramic, to crack or shatter.

Instead, open the door just a small slit first. This allows the temperature to drop more gradually and safely. Once the furnace has cooled significantly, you can fully open the door and remove items using long-handled crucible tongs to prevent burns.

Understanding the Risks and Trade-offs

Recognizing the inherent dangers of a muffle furnace is key to respecting the safety protocols. The rules are in place to mitigate specific, well-understood hazards.

The Risk of Thermal Shock

The primary trade-off during cooldown is speed versus equipment integrity. While you may want to access your sample quickly, rushing the process by opening the door prematurely puts the expensive furnace lining at risk. A cracked chamber is a costly failure that renders the furnace unusable.

The Hazard of Electrical Failure

There is no trade-off for electrical safety. Improper grounding or using an underrated circuit is not a shortcut; it is a direct invitation for equipment failure, fire, or fatal electric shock. The initial setup must be done correctly without compromise.

The Danger of Operator Error

Most operational incidents, from burns to broken thermocouples, stem from a lack of discipline or awareness. Attempting to handle items before they have sufficiently cooled or being careless when loading crucibles are common and avoidable mistakes. Patience is a critical safety tool.

Making the Right Choice for Your Goal

Implementing a robust safety protocol requires tailoring your focus to your specific role and responsibilities.

- If your primary focus is facility management or lab safety: Prioritize the infrastructure, ensuring all furnaces have verified grounding, dedicated circuits, and are located in designated, clear zones with proper fire suppression equipment.

- If your primary focus is daily operation: Concentrate on disciplined procedure, including meticulous pre-use checks, careful handling of materials to protect the thermocouple, and strict adherence to the gradual cooldown protocol.

- If your primary focus is training new users: Emphasize the "why" behind the rules, explaining the dangers of thermal shock, electrical faults, and radiant heat to build a deep-seated respect for the equipment.

Ultimately, consistent adherence to these safety principles transforms them from a checklist into an ingrained habit, ensuring a safe and reliable operational environment.

Summary Table:

| Emergency Measure | Key Actions |

|---|---|

| Electrical Safety | Ensure proper grounding, use dedicated circuits, install rubber mats |

| Fire Prevention | Maintain clear zone, keep fire extinguisher accessible, avoid flammable materials |

| Operational Safety | Train on thermal shock risks, handle materials carefully, follow cooldown protocols |

| Environmental Setup | Place on stable ground, fill thermocouple gaps with asbestos rope |

Ensure your lab's safety with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide muffle furnaces, tube furnaces, rotary furnaces, vacuum & atmosphere furnaces, and CVD/PECVD systems tailored to your needs. Our strong deep customization capability precisely meets unique experimental requirements, enhancing reliability and preventing emergencies. Contact us today to discuss how our products can safeguard your operations and boost efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO