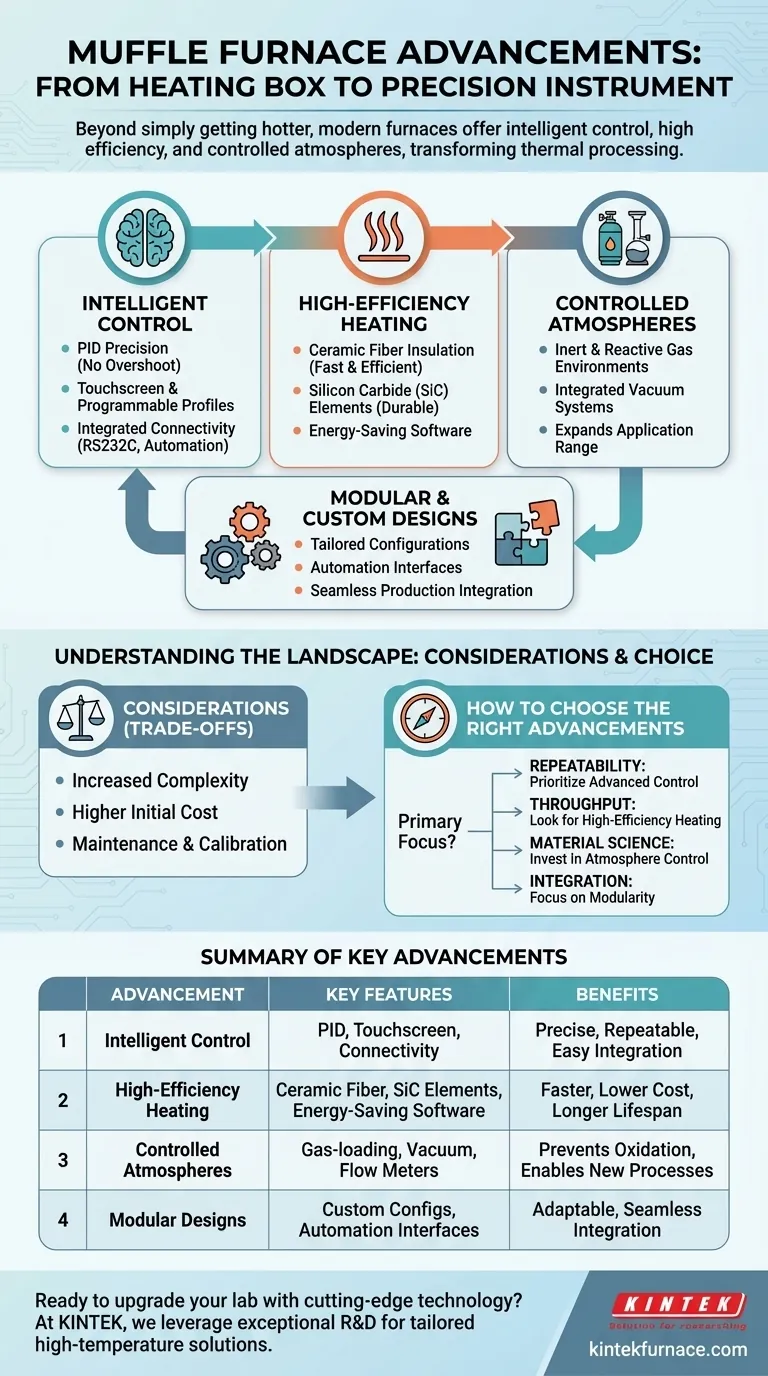

Modern muffle furnaces are evolving far beyond simple heating boxes. The latest technological advancements are centered on intelligent process control, high-efficiency materials, controlled atmospheres, and modular designs. These innovations transform the furnace from a basic tool into a precise, repeatable, and integrated piece of laboratory or production equipment.

Beyond simply getting hotter, today's muffle furnaces are defined by precision, efficiency, and adaptability. The core evolution is the shift from a basic heating device to a highly controlled, programmable process environment tailored to specific scientific and industrial outcomes.

From Manual to Intelligent: The Control Revolution

The single most significant advancement is the move from analog dials to sophisticated digital control systems. This fundamentally changes the reliability and repeatability of thermal processes.

Precision with PID Control

Modern furnaces use Proportional-Integral-Derivative (PID) controllers. These intelligent systems continuously monitor the temperature and make micro-adjustments to the heating elements.

This eliminates the temperature "overshoot" common in older models, ensuring the set temperature is reached quickly and maintained with extreme accuracy, which is critical for sensitive processes like annealing or thermogravimetric analysis.

The Rise of Digital Interfaces

Simple dials and readouts have been replaced by touchscreen interfaces. This allows operators to easily program multi-step heating profiles with different ramps, holds, and cooling rates.

These programs can be saved and recalled, ensuring that every batch or experiment is run under the exact same thermal conditions, which is essential for quality control and valid scientific comparison.

Integration and Automation

Modern furnaces are designed to be part of a larger system. They often include communication ports (like RS232C) and various output terminals.

This enables the furnace to be controlled by a central computer, to log temperature data automatically, and to trigger external events like alarms or signal other machinery when a cycle is complete.

Redefining Efficiency: Faster, Smarter Heating

Driven by rising energy costs and the need for higher throughput, manufacturers have focused heavily on improving the core performance and efficiency of the furnace chamber.

Advanced Insulation Materials

Traditional heavy brick insulation is being replaced with lightweight ceramic fiber. This material offers superior thermal insulation with much lower thermal mass.

The result is significantly faster heat-up and cool-down times, which increases laboratory or factory throughput. It also makes the furnaces more energy-efficient, as less energy is wasted heating the insulation itself.

High-Performance Heating Elements

Silicon carbide (SiC) heating elements are increasingly common. They are highly durable and can operate efficiently at very high temperatures for extended periods.

This longevity reduces maintenance downtime and replacement costs compared to traditional metallic wire elements, especially in demanding, high-temperature applications like sintering technical ceramics.

Energy-Saving Software

Intelligent controllers now include energy-saving functions, such as automatic power adjustment. The furnace can optimize power consumption during long hold times, reducing electricity usage without compromising temperature stability.

Beyond Air: Mastering the Process Atmosphere

Perhaps the most transformative advancement is the ability to precisely control the chemical environment inside the furnace, opening up a vast range of new applications.

Creating Inert and Reactive Environments

Many furnaces now come equipped with gas-loading devices and flow meters. This allows for a controlled atmosphere of inert gas, such as nitrogen, to be introduced.

This capability is crucial for processes where oxidation is undesirable, such as brazing or sintering metal powders. It can also be used with reactive gases, like hydrogen, for specific chemical reduction processes.

The Role of Vacuum Systems

Integrated vacuum packages are another key feature. The ability to pull a vacuum within the chamber is essential for processes like debinding in metal injection molding or degassing materials.

Understanding the Trade-offs

While these advancements offer significant benefits, they also introduce new considerations that every user must evaluate.

Increased Complexity

A furnace with multi-gas atmosphere control and a programmable PID interface is inherently more complex than a simple "set-and-forget" model. It requires more training for operators to use effectively.

Higher Initial Cost

Features like vacuum systems, advanced controllers, and gas-handling packages add to the initial purchase price of the furnace. The investment must be justified by the requirements of your specific process.

Maintenance and Calibration

Intelligent control systems and gas flow meters require periodic calibration to ensure continued accuracy. This adds a maintenance overhead that is not present with simpler, older equipment.

How to Choose the Right Advancements for Your Needs

Focus on the advancements that solve your specific problem rather than pursuing every new feature.

- If your primary focus is process repeatability and data integrity: Prioritize a furnace with an advanced PID controller and digital data logging capabilities.

- If your primary focus is high throughput and lowering operational costs: Look for designs with ceramic fiber insulation and energy-saving software modes.

- If your primary focus is material science and advanced research: Atmosphere control (gas and/or vacuum) is the most critical advancement to invest in.

- If your primary focus is integrating into a specific production line: Modularity, custom configurations (like tilting or rotating), and automation interfaces are your key considerations.

By understanding these advancements, you can select a tool that is not just a furnace, but a precise instrument engineered for your specific goals.

Summary Table:

| Advancement | Key Features | Benefits |

|---|---|---|

| Intelligent Control | PID controllers, touchscreen interfaces, automation ports | Precise temperature control, repeatable processes, easy integration |

| High-Efficiency Heating | Ceramic fiber insulation, silicon carbide elements, energy-saving software | Faster heat-up/cool-down, reduced energy costs, longer lifespan |

| Controlled Atmospheres | Gas-loading devices, vacuum systems, flow meters | Prevents oxidation, enables reactive processes, expands application range |

| Modular Designs | Custom configurations, automation interfaces | Adaptability to specific needs, seamless production line integration |

Ready to upgrade your lab with cutting-edge muffle furnace technology? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our innovations can enhance your precision, efficiency, and process control!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control