At their core, box furnaces are defined by four standard features: fully programmable temperature control, exceptional temperature uniformity, robust physical construction for longevity, and highly reliable, efficient heating systems. These elements work in concert to deliver precise and repeatable thermal processing for a wide range of demanding applications.

A box furnace is not just a simple heated box. It is an engineered system designed for process integrity, where sophisticated controls, uniform heating dynamics, and energy-efficient construction combine to ensure consistent, reliable results.

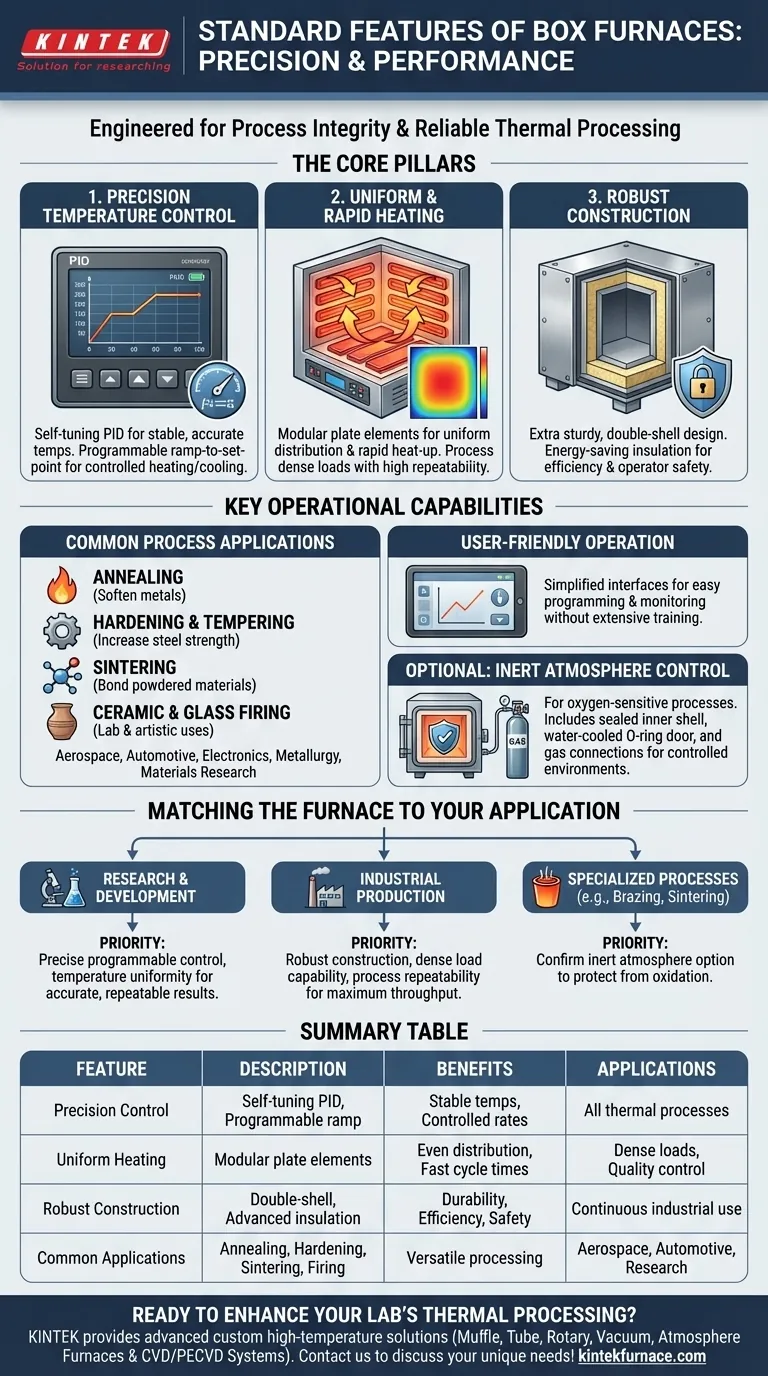

The Core Pillars of Box Furnace Design

A modern box furnace is built on a foundation of control, efficiency, and durability. Each feature is a critical component that enables its performance in both laboratory and industrial settings.

Precision Temperature Control

The defining characteristic of a box furnace is its ability to precisely manage temperature. Control consoles use self-tuning PID (Proportional-Integral-Derivative) instrumentation.

This system automatically calculates the optimal settings for the specific thermal process, ensuring stable and accurate temperatures without overshoot.

A key feature is the programmable ramp-to-setpoint capability. This allows users to define the exact rate of heating and cooling, which is critical for materials that are sensitive to thermal shock.

Uniform and Rapid Heating

Box furnaces are engineered for highly uniform temperature distribution throughout the chamber. This ensures that every part of a load, regardless of its position, experiences the same thermal conditions.

They utilize modular plate heating elements known for their longevity and ability to heat up rapidly. This design avoids the typical watt loading limitations of other element types, enabling faster cycle times.

This combination of uniform heat and rapid response allows for processing dense loads and ensures high process repeatability, a crucial factor for quality control in production.

Robust and Efficient Construction

A standard box furnace features extra sturdy, double-shell construction. This design, combined with advanced, energy-saving insulation, minimizes heat loss and reduces external surface temperatures, improving both efficiency and operator safety.

This robust build quality ensures the furnace can withstand the rigors of continuous industrial use over a long service life. Premium components are used throughout to guarantee high reliability.

Key Operational Capabilities

The standard design features directly translate into a versatile and user-friendly operational tool suitable for a variety of sectors.

Common Process Applications

Box furnaces are workhorses in materials science and manufacturing. They are routinely used for processes such as:

- Annealing: To soften metals and relieve internal stresses.

- Hardening & Tempering: To increase the hardness and toughness of steel.

- Sintering: To bond powdered materials together at high temperatures.

- Ceramic & Glass Firing: Used widely in labs and artistic applications.

These capabilities make them essential in industries like aerospace, automotive, electronics, metallurgy, and materials research.

User-Friendly Operation

Despite their sophisticated internal systems, box furnaces are designed with user-friendly control interfaces. This simplifies programming and monitoring, making complex thermal cycles accessible to operators without extensive training.

Understanding Optional Configurations

While the features above are standard, many applications require specialized environments. The most common optional feature is for atmosphere control.

Inert Atmosphere Control

For processes that cannot be exposed to oxygen, box furnaces can be equipped with an inert atmosphere gas-sealed option.

This upgrade typically includes a completely sealed inner shell, a water-cooled O-ring sealed door, and gas or water-cooled electrical connections to maintain the integrity of the controlled atmosphere.

In some bottom-loading furnace designs, a removable atmosphere dome may be used for high-temperature operations under a specific gas environment.

Matching the Furnace to Your Application

Choosing a furnace means aligning its features with your primary goal.

- If your primary focus is research and development: Prioritize precise programmable control and temperature uniformity to ensure accurate, repeatable experimental results.

- If your primary focus is industrial production: Emphasize robust construction, dense load capability, and process repeatability for maximum throughput and reliability.

- If your primary focus is a specialized process like brazing or sintering: Confirm the availability and specifications of the inert atmosphere option to protect your materials from oxidation.

Understanding these standard and optional features empowers you to select a box furnace that will serve as a reliable tool for achieving your specific thermal processing outcomes.

Summary Table:

| Feature | Description |

|---|---|

| Precision Temperature Control | Uses self-tuning PID and programmable ramp-to-setpoint for stable, accurate heating and cooling. |

| Uniform and Rapid Heating | Modular plate elements ensure even temperature distribution and fast cycle times for dense loads. |

| Robust Construction | Double-shell design with energy-saving insulation for durability, efficiency, and operator safety. |

| Common Applications | Annealing, hardening, sintering, and ceramic firing in aerospace, automotive, and research sectors. |

Ready to enhance your lab's thermal processing with a custom box furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures we meet your unique experimental needs—contact us today to discuss how we can deliver precise, reliable results for your applications!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a laboratory muffle furnace play in high-purity alpha-alumina prep? Master Calcination and Phase Shifts

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What role does a box muffle furnace play during the pre-carbonization stage of sugarcane bagasse? Expert Insights

- What is the function of a high-temperature Muffle Furnace in the two-step heat treatment of PTFE-coated Nickel Foam?