In essence, a muffle furnace provides three primary advantages over other heating methods: exceptionally precise and uniform temperature control, complete isolation of the sample from heating elements and contaminants, and robust operational safety. These benefits stem from its core design, where a sample is placed inside a sealed chamber (the "muffle") that is then heated externally, ensuring the heating process is both clean and perfectly controlled.

The core value of a muffle furnace is not just its ability to reach high temperatures, but its capacity to create a pristine and stable thermal environment. This makes it an indispensable tool for applications where process integrity and repeatability are paramount.

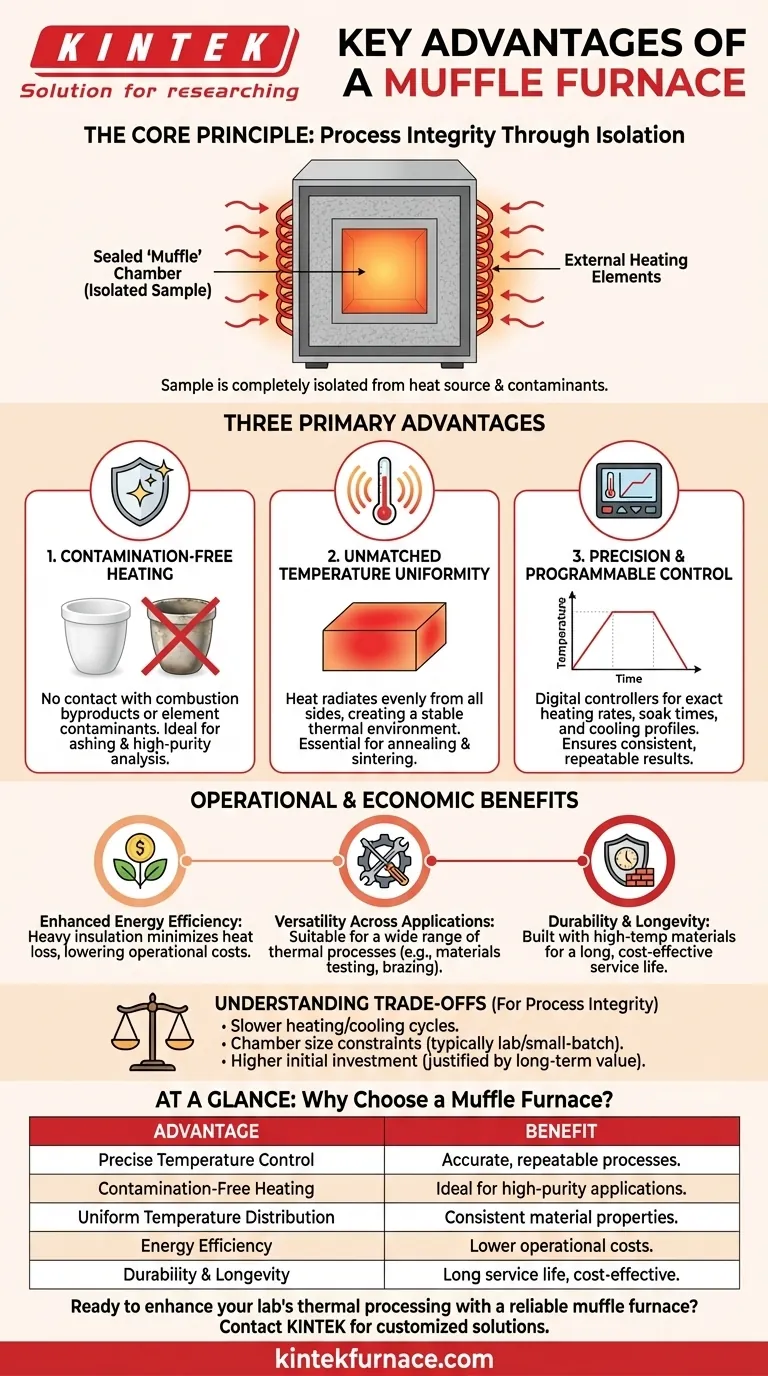

The Core Principle: Process Integrity Through Isolation

A muffle furnace's unique advantages are a direct result of its fundamental design: separating the heat source from the material being processed. This separation is the key to understanding its value.

Contamination-Free Heating

The term "muffle" refers to the insulated, sealed inner chamber that holds the sample. Heating elements are located outside this chamber.

This design prevents any byproducts of combustion or contaminants from the heating elements from ever touching the sample. This is critical for processes like ashing, where the goal is to burn off organic material to precisely measure the non-combustible remainder.

Unmatched Temperature Uniformity

Because the heating elements typically surround the muffle, heat radiates inward from multiple sides.

This creates an exceptionally uniform thermal environment. Every part of the sample experiences the same temperature, which is essential for sensitive heat-treatment processes like annealing or sintering, where inconsistent temperatures can ruin the final product's structural integrity.

Precision and Control

Modern muffle furnaces are equipped with sophisticated digital controllers.

These controllers allow users to program precise heating rates, specific temperature "soak" times, and controlled cooling profiles. This level of automation ensures that processes are not only accurate but also perfectly repeatable from one batch to the next.

Operational and Economic Advantages

Beyond its core function, the muffle furnace design delivers significant practical benefits that make it a mainstay in laboratories and specialized industrial settings.

Enhanced Energy Efficiency

The heavy insulation required to protect the external heating elements also serves to minimize heat loss to the surrounding environment.

Compared to direct-fired furnaces or open-flame heating, a well-sealed muffle furnace is significantly more energy-efficient, reducing operational costs over its lifetime.

Versatility Across Applications

The controlled, clean environment of a muffle furnace makes it suitable for a vast range of thermal processes.

Common applications include materials testing, soldering, brazing, enameling, and creating high-purity metals and glass. Some models also allow for the introduction of specific atmospheres (like nitrogen or argon) to prevent oxidation.

Durability and Longevity

These furnaces are built to withstand extreme thermal cycling.

They are constructed from robust, high-temperature-resistant materials like refractory ceramics and specialized metal alloys. This durable construction ensures a long service life, making the initial investment highly cost-effective over time.

Understanding the Trade-offs

No tool is perfect for every job. The design that gives the muffle furnace its advantages also introduces certain limitations.

Slower Heating and Cooling Cycles

The same insulation and thermal mass that ensure temperature stability and efficiency also mean the furnace takes longer to heat up and cool down compared to direct heating methods.

This is a necessary trade-off for achieving process precision and is not ideal for applications requiring extremely rapid thermal changes.

Chamber Size and Volume Constraints

Muffle furnaces are typically designed for laboratory-scale or small-batch production.

Building a very large muffle while maintaining perfect temperature uniformity is complex and expensive. For processing very large parts or high-volume throughput, other furnace types may be more practical.

Initial Cost

The specialized materials, advanced insulation, and precision controllers make a muffle furnace a more significant capital investment than a simple convection oven or a basic forge. However, this cost is often justified by its energy efficiency, process reliability, and long service life.

Making the Right Choice for Your Application

Selecting the right heating instrument depends entirely on your primary objective.

- If your primary focus is analytical purity (e.g., ashing, trace element analysis): The muffle furnace is the only suitable choice due to its absolute sample isolation.

- If your primary focus is uniform heat treatment (e.g., annealing, sintering, glass tempering): The superior temperature uniformity of a muffle furnace ensures consistent and reliable material properties.

- If your primary focus is simply rapid heating for bulk material: A direct-fired or induction furnace may be a more time-efficient option, provided you can accept potential surface contamination or less precise temperature control.

Ultimately, choosing a muffle furnace is a decision to prioritize the integrity and repeatability of your thermal process above all else.

Summary Table:

| Advantage | Description |

|---|---|

| Precise Temperature Control | Enables accurate heating rates and repeatable processes with digital controllers. |

| Contamination-Free Heating | Isolates samples from heating elements, ideal for ashing and high-purity applications. |

| Uniform Temperature Distribution | Radiates heat evenly for consistent results in annealing and sintering. |

| Energy Efficiency | Heavy insulation reduces heat loss, lowering operational costs. |

| Durability and Longevity | Built with high-temperature materials for long service life and cost-effectiveness. |

| Versatility | Suitable for various applications like materials testing, soldering, and brazing. |

Ready to enhance your lab's thermal processing with a reliable muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're in research, materials science, or industrial production, our furnaces deliver precise temperature control, contamination-free heating, and energy efficiency to ensure process integrity and repeatability. Contact us today to discuss how we can tailor a solution for you!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production