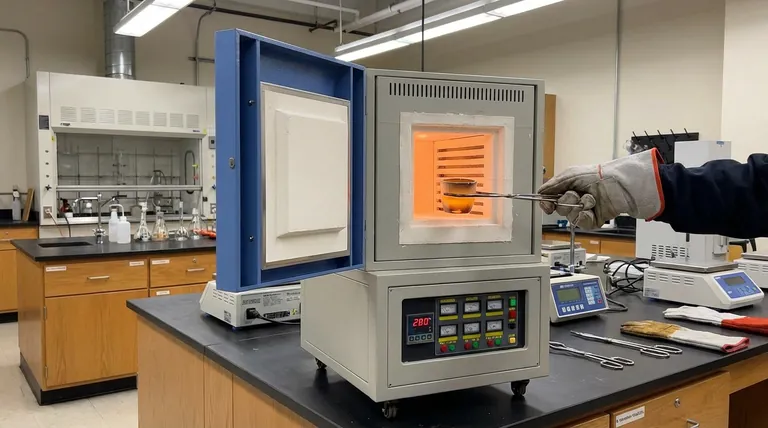

A high-temperature muffle furnace functions as a precise thermal buffer used to control the cooling rate of Phosphor-in-Glass Composites (PGC). Specifically, the furnace is pre-set to an annealing temperature of 280°C to receive the material immediately after the rapid mixing and casting phase, preventing the structural shock associated with sudden temperature drops.

The core purpose of this annealing step is to manage the transition from a molten state to a solid state. By providing a controlled, slow cooling environment, the muffle furnace eliminates internal thermal stresses caused by rapid quenching, ensuring the material remains crack-free and optically stable.

The Critical Role of Thermal Regulation

Immediate Temperature Stabilization

In the synthesis of PGC, the timing of the annealing process is vital. The high-temperature muffle furnace must be pre-set to 280°C before the synthesis begins.

Immediately following the casting of the PGC material, the sample is transferred directly into this heated environment. This rapid transfer prevents the material from cooling uncontrolled in ambient air, which would lead to immediate thermal shock.

Controlled Slow Cooling

Once the sample is inside the 280°C environment, the furnace facilitates a controlled slow cooling process.

Unlike rapid quenching, which freezes atoms in unstable positions, slow cooling allows the material to reach thermal equilibrium gradually. High-performance insulation and programmable control systems within the furnace ensure this cooling curve is exceptionally stable.

Why Annealing is Non-Negotiable for PGC

Eliminating Internal Thermal Stress

The casting process for PGC involves rapid mixing and quenching, which naturally introduces significant internal tension.

Without intervention, these residual stresses remain trapped within the glass matrix. The muffle furnace provides the thermal energy necessary to relax these stresses, effectively "resetting" the internal structure of the composite.

Preventing Structural Failure

The most immediate risk during PGC synthesis is sample cracking.

If the material cools too quickly, the differential contraction between the surface and the core causes fractures. The annealing step at 280°C is the primary defense against this, ensuring the physical integrity of the final sample.

Ensuring Optical Stability

Beyond preventing cracks, the annealing process stabilizes the optical performance of the composite.

By removing stress and optimizing the material's stability, the furnace ensures that the phosphor particles embedded within the glass maintain consistent light conversion properties.

Understanding the Trade-offs

While the muffle furnace is essential for quality, it introduces specific variables that must be managed.

Process Duration vs. Throughput Annealing is inherently a bottleneck. The requirement for slow cooling extends the total production time significantly compared to rapid air cooling. Rushing this stage to increase throughput will almost invariably lead to compromised mechanical properties or latent defects.

Equipment Precision Not all furnaces deliver the same results. A furnace with poor insulation or fluctuating temperature controls can introduce uneven cooling rates. If the furnace cannot maintain a uniform 280°C environment or a smooth cooling ramp, it may induce the very stresses it is meant to eliminate.

Making the Right Choice for Your Goal

To maximize the utility of your high-temperature muffle furnace for PGC synthesis, consider your specific objectives:

- If your primary focus is Structural Integrity: Prioritize the immediate transfer of the sample to the 280°C furnace to mitigate the risks of rapid quenching and cracking.

- If your primary focus is Optical Performance: Focus on programming a highly gradual cooling curve to ensure maximum stability and stress relief within the glass matrix.

The effective use of a muffle furnace is not just about reaching high temperatures; it is about the precise control of thermal decline to preserve material quality.

Summary Table:

| Feature | Function in PGC Annealing | Benefit to Final Composite |

|---|---|---|

| Pre-set Temp (280°C) | Immediate thermal stabilization post-casting | Prevents structural shock and rapid quenching |

| Controlled Cooling | Gradual transition from molten to solid state | Eliminates internal thermal stress and fractures |

| Insulation Quality | Ensures uniform temperature distribution | Maintains consistent optical properties |

| Programmable Ramping | Precise control of the cooling curve | Maximizes material stability and durability |

Elevate Your PGC Synthesis with KINTEK Precision

Don’t let thermal stress compromise your material's optical performance. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, and Vacuum systems, specifically designed to handle the rigorous demands of material synthesis and annealing.

Backed by expert R&D and precision manufacturing, our lab high-temperature furnaces are fully customizable to meet your unique cooling ramps and temperature requirements. Ensure crack-free results and superior stability for your composites today.

Contact KINTEK for a Custom Solution

References

- Yongsheng Sun, Zhiguo Xia. Rapid synthesis of phosphor-glass composites in seconds based on particle self-stabilization. DOI: 10.1038/s41467-024-45293-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of a muffle furnace in Ba1-xCaxTiO3 calcination? Ensure Purity & Precision in Ceramic Synthesis

- What are the different heating methods used in muffle furnaces and drying ovens? Choose the Right Tool for Your Lab

- How is a laboratory box resistance furnace utilized in the heat treatment and testing of high-speed steel samples?

- What temperature ranges can muffle furnaces achieve? Find the Perfect Heat for Your Lab Needs

- How does a high-temperature box resistance furnace synthesize WC/C@N-S nanocatalysts? Precision Thermal Control

- What is the core function of a muffle furnace during the pyrolysis of Licuri bark? Engineering Porosity and Carbon Yield

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What are the key considerations for temperature control when using a Muffle furnace? Master Precise Thermal Management