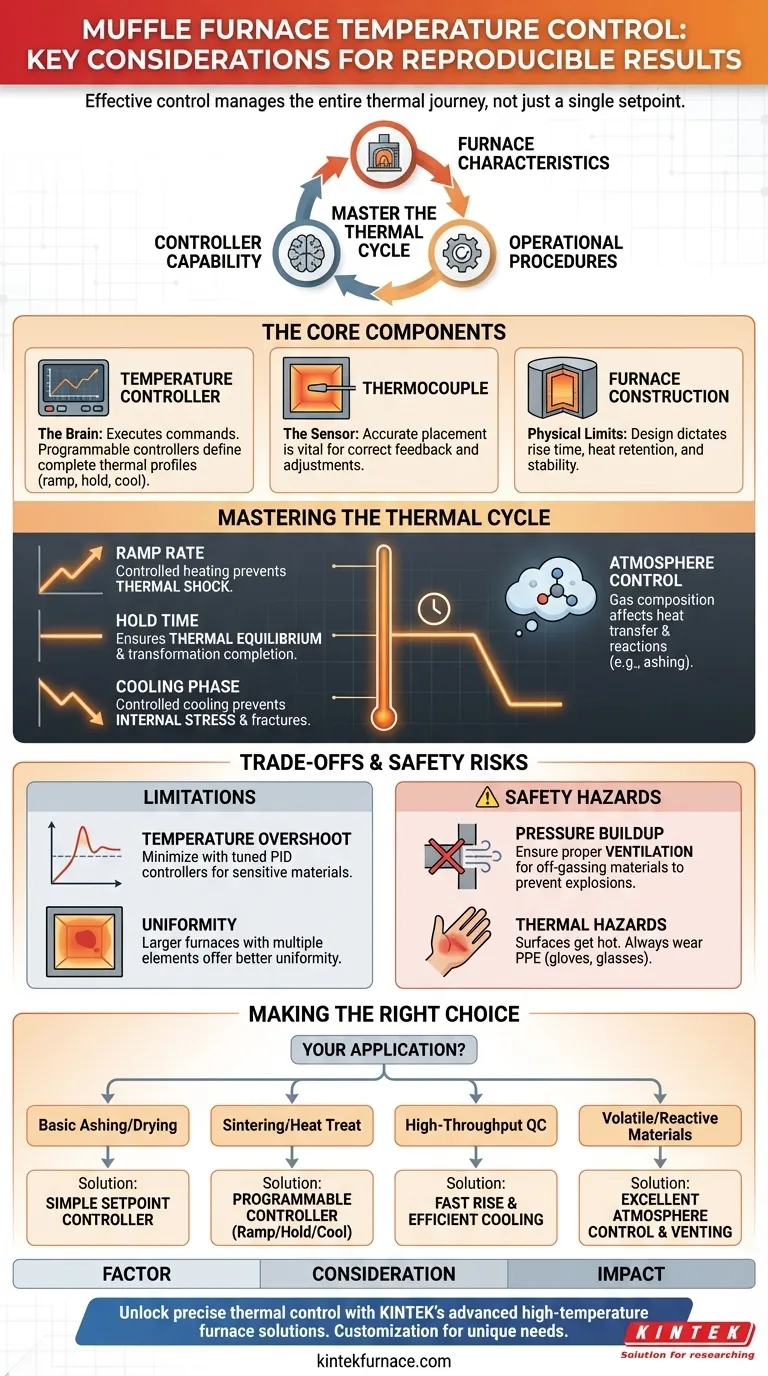

In short, effective temperature control in a muffle furnace depends on three factors: the capability of your temperature controller, the physical characteristics of the furnace itself, and your adherence to precise operational procedures. The key is to manage not just a single temperature but the entire heating and cooling cycle, including the ramp rate, hold time, and atmosphere.

True mastery of a muffle furnace isn't about reaching a target temperature. It's about controlling the entire thermal journey of your material to guarantee reproducible outcomes and ensure operational safety.

The Core Components of Temperature Control

To achieve precise results, you must first understand the system's components. The furnace is more than a hot box; it is an integrated system where each part plays a critical role in managing heat.

The Temperature Controller: The Brain of the Operation

The temperature controller is the central component that executes your commands. Its sophistication directly impacts the precision of your work.

Basic controllers allow you to set a single target temperature (a setpoint). The furnace heats until it reaches that point and then works to maintain it.

More advanced programmable controllers are essential for most scientific and industrial processes. They allow you to define a complete thermal profile, including multi-step ramp rates, specific hold (or "dwell") times, and controlled cooling periods.

The Thermocouple: The Eyes and Ears

The controller relies on a sensor, typically a thermocouple, placed inside the chamber to measure the actual temperature. The accuracy and placement of this thermocouple are vital for the controller to make correct adjustments.

An inaccurate or poorly placed sensor will feed the controller false information, making precise control impossible.

Furnace Construction: The Physical Limits

The furnace's physical design dictates its thermal performance. Key factors include the maximum operating temperature, insulation quality, and chamber volume.

These characteristics determine the rise time (how quickly it can reach max temperature) and how well it retains heat, which affects stability and energy consumption. A furnace with a maximum temperature rating slightly above your typical operating needs will ensure a longer equipment lifespan.

Mastering the Thermal Cycle for Consistent Results

Controlling temperature is an active process throughout the entire heating and cooling cycle. Each phase has a distinct purpose and impact on your final material.

Setting the Ramp Rate

The ramp rate is the speed at which the temperature increases, measured in degrees per minute or hour. A controlled ramp-up is crucial for preventing thermal shock, which can crack or damage sensitive materials like ceramics.

The Importance of Hold (Dwell) Time

Hold time is the period the furnace maintains a stable target temperature. This ensures the entire sample—including its core—reaches thermal equilibrium and that the desired physical or chemical transformation has sufficient time to complete.

Managing the Cooling Phase

The cooling process is often as critical as the heating process. Uncontrolled, rapid cooling can introduce internal stresses and fractures in a material. A programmable controller allows for a gradual, controlled cooling ramp to preserve the material's integrity.

Atmosphere Control: The Hidden Variable

The composition of the gas inside the furnace chamber significantly affects heat transfer and material reactions. Adjusting air intake and exhaust ports controls whether the atmosphere is oxidizing or relatively inert.

This control is essential for processes like ashing and can influence the final properties of heat-treated metals.

Understanding Trade-offs and Safety Risks

Perfect control is an ideal. In practice, you must manage inherent limitations and potential hazards.

Temperature Overshoot and Stability

Overshoot is a common phenomenon where the furnace temperature temporarily exceeds the setpoint before stabilizing. A high-quality controller with a well-tuned PID (Proportional-Integral-Derivative) algorithm minimizes this effect, which is critical for temperature-sensitive materials.

Uniformity vs. Cost

Achieving perfect temperature uniformity across the entire chamber is challenging. Larger, more expensive furnaces often have multiple heating elements and better designs to minimize hot and cold spots. For smaller furnaces, placing your sample in the center of the chamber typically yields the most consistent results.

Critical Safety: Preventing Pressure Buildup

Many materials release gases, moisture, or fumes when heated. If the furnace's exhaust port is blocked or insufficient for the volume of gas being produced, pressure can build inside the chamber, creating a risk of a sudden release or even an explosion. Always ensure proper ventilation.

Thermal Hazards

The exterior surfaces of a muffle furnace can become extremely hot, posing a severe burn risk. Always wear appropriate personal protective equipment (PPE), such as heat-resistant gloves and safety glasses, and be aware of fire hazards in the surrounding area.

Making the Right Choice for Your Process

Your specific application determines the level of control you require.

- If your primary focus is basic ashing or drying: A simple, reliable furnace with a basic setpoint controller may be sufficient.

- If your primary focus is material sintering or complex heat treatment: A programmable controller with precise ramp, hold, and cooling control is non-negotiable.

- If your primary focus is high-throughput quality control: Prioritize a furnace with a fast rise time and efficient cooling to maximize the number of cycles you can run.

- If you are working with volatile or reactive materials: Select a furnace with excellent atmosphere control and ventilation features to ensure both safety and process integrity.

By understanding these principles, you can move beyond simply setting a temperature and begin to truly direct the thermal process to achieve your desired outcome.

Summary Table:

| Component / Factor | Key Consideration | Impact on Control |

|---|---|---|

| Temperature Controller | Programmable vs. basic; PID tuning | Precision of thermal profiles, minimizes overshoot |

| Thermocouple | Accuracy and placement | Reliable temperature measurement |

| Furnace Construction | Max temperature, insulation, chamber volume | Rise time, heat retention, stability |

| Ramp Rate | Controlled speed (degrees/min or hour) | Prevents thermal shock, ensures material integrity |

| Hold Time | Duration at target temperature | Achieves thermal equilibrium, completes transformations |

| Cooling Phase | Controlled vs. rapid cooling | Reduces internal stresses, preserves material |

| Atmosphere Control | Gas composition (oxidizing/inert) | Affects heat transfer and material reactions |

| Safety | Ventilation, PPE, pressure buildup | Prevents hazards like explosions and burns |

Unlock precise thermal control for your laboratory with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle Furnaces and other products like Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, enhancing reproducibility and safety. Contact us today to discuss how we can optimize your processes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care