In short, required training for a muffle furnace operator covers four critical areas: standard operating procedures, comprehensive safety guidelines, emergency protocols, and routine maintenance practices. This training ensures the operator understands how to use the equipment correctly and can respond effectively to any situation, minimizing risks to personnel and the equipment itself.

True operational competence goes beyond just knowing which buttons to press. It requires a holistic understanding of the furnace as a high-energy system, including its environmental requirements, its operational limits, and the crucial safety procedures that govern its use.

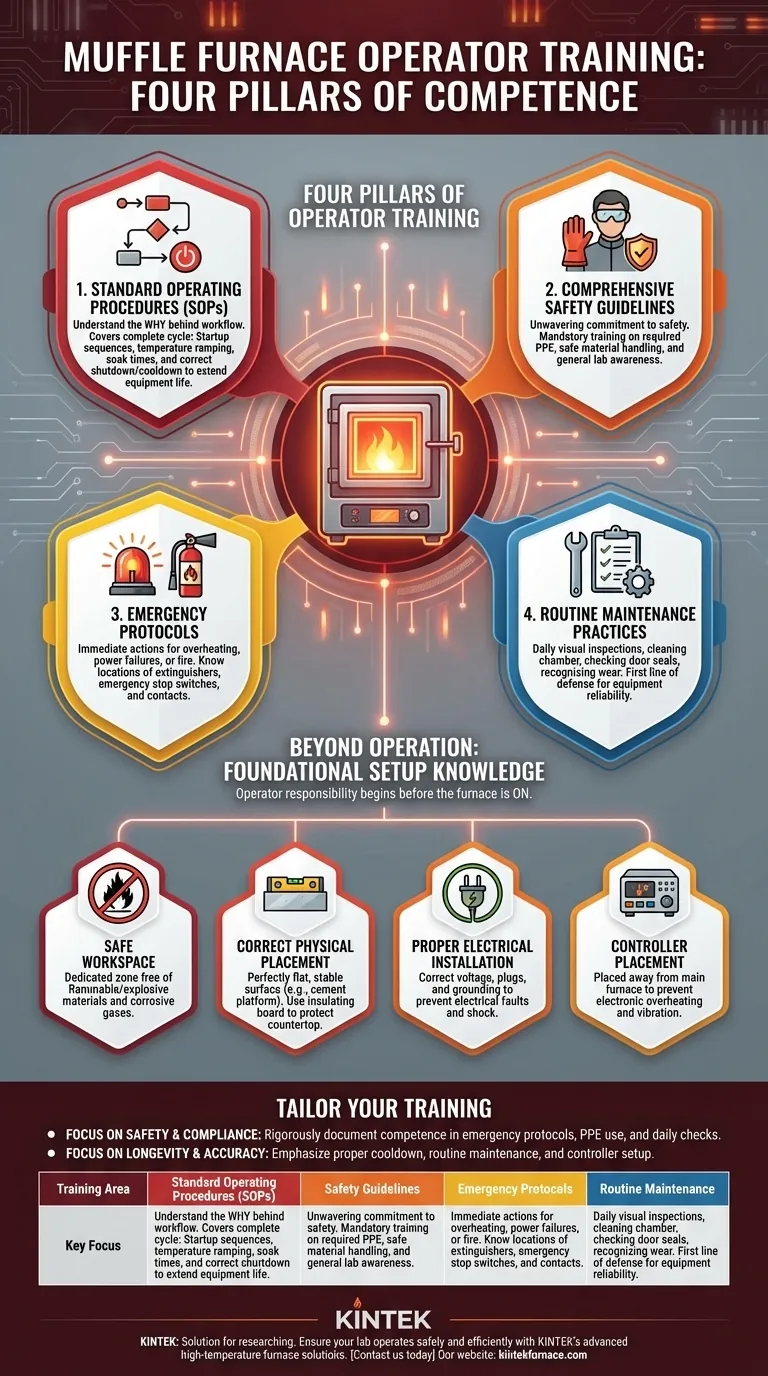

The Four Pillars of Operator Training

Effective training is built on a foundation of four distinct but interconnected knowledge areas. Mastery of each is non-negotiable for safe and efficient operation.

1. Standard Operating Procedures (SOPs)

An operator must have an intuitive command of the furnace's entire workflow. This is not about memorizing a manual but about understanding the why behind each step.

Training must cover the complete cycle: proper startup sequences, setting and ramping temperature profiles, soak times, and, crucially, correct shutdown and cooldown procedures to prevent thermal shock and extend equipment life.

2. Comprehensive Safety Guidelines

Working with extreme temperatures necessitates an unwavering commitment to safety. This part of the training is the most critical for preventing injury.

Operators must be trained on required Personal Protective Equipment (PPE) like thermal gloves and safety glasses, safe handling of materials being placed in or removed from the furnace, and general lab awareness.

3. Emergency Protocols

When things go wrong, a trained operator's response can be the difference between a minor issue and a major incident. Hope is not a strategy.

This includes immediate actions for overheating, unexpected shutdowns, power failures, or—in a worst-case scenario—fire. Operators must know the location of fire extinguishers, emergency power-off switches, and who to contact.

4. Routine Maintenance Practices

A well-maintained furnace is a safer and more reliable furnace. Operators are the first line of defense in identifying potential issues before they become critical failures.

Training should cover daily visual inspections, cleaning the chamber of residue, checking door seals, and recognizing signs of wear on heating elements or thermocouples. It also includes knowing when a problem requires a qualified service technician.

Beyond Operation: Foundational Setup Knowledge

An operator's responsibility begins before the furnace is even turned on. The environment and setup are foundational to safety, and every operator must be trained to verify these conditions are met before every use.

The Requirement for a Safe Workspace

The immediate area around the furnace must be a dedicated zone. This is an absolute rule.

The workspace must be completely free of flammable materials, explosive substances, and corrosive gases. A pre-operation check of the surrounding area is a mandatory safety step.

Correct Physical Placement

A furnace's stability and insulation are critical. It cannot be placed on just any workbench.

It must be on a perfectly flat and stable surface, such as a dedicated cement platform. Placing an asbestos board or similar insulator underneath is a wise practice to protect the countertop from extreme heat damage.

Proper Electrical Installation

Improper electrical connections are a primary source of fire and electrical shock hazards.

The furnace must be connected to a properly rated circuit with the correct plugs, sockets, and fuses. Most importantly, the unit must be properly grounded to prevent electrical faults from energizing the chassis.

Controller Placement

The furnace's "brain"—the temperature controller—is sensitive to its environment.

The controller unit should be placed away from the main furnace body to prevent its electronic components from overheating. It should also be in a location free from vibration, which can disrupt its function and lead to inaccurate temperature control.

Making the Right Choice for Your Goal

To implement a truly effective program, tailor your training emphasis to your primary objectives.

- If your primary focus is safety and compliance: Your training must rigorously document operator competence in emergency protocols, PPE use, and daily pre-operation environmental checks.

- If your primary focus is equipment longevity and process accuracy: Emphasize training on proper cooldown procedures, routine maintenance checks, and correct controller placement and programming.

Ultimately, a well-trained operator is the core component of a safe, efficient, and reliable high-temperature process.

Summary Table:

| Training Area | Key Focus |

|---|---|

| Standard Operating Procedures (SOPs) | Startup, temperature control, shutdown sequences |

| Safety Guidelines | PPE use, material handling, lab awareness |

| Emergency Protocols | Overheating, power failure, fire response |

| Routine Maintenance | Daily inspections, cleaning, wear recognition |

Ensure your lab operates safely and efficiently with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how we can support your training and equipment requirements!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing