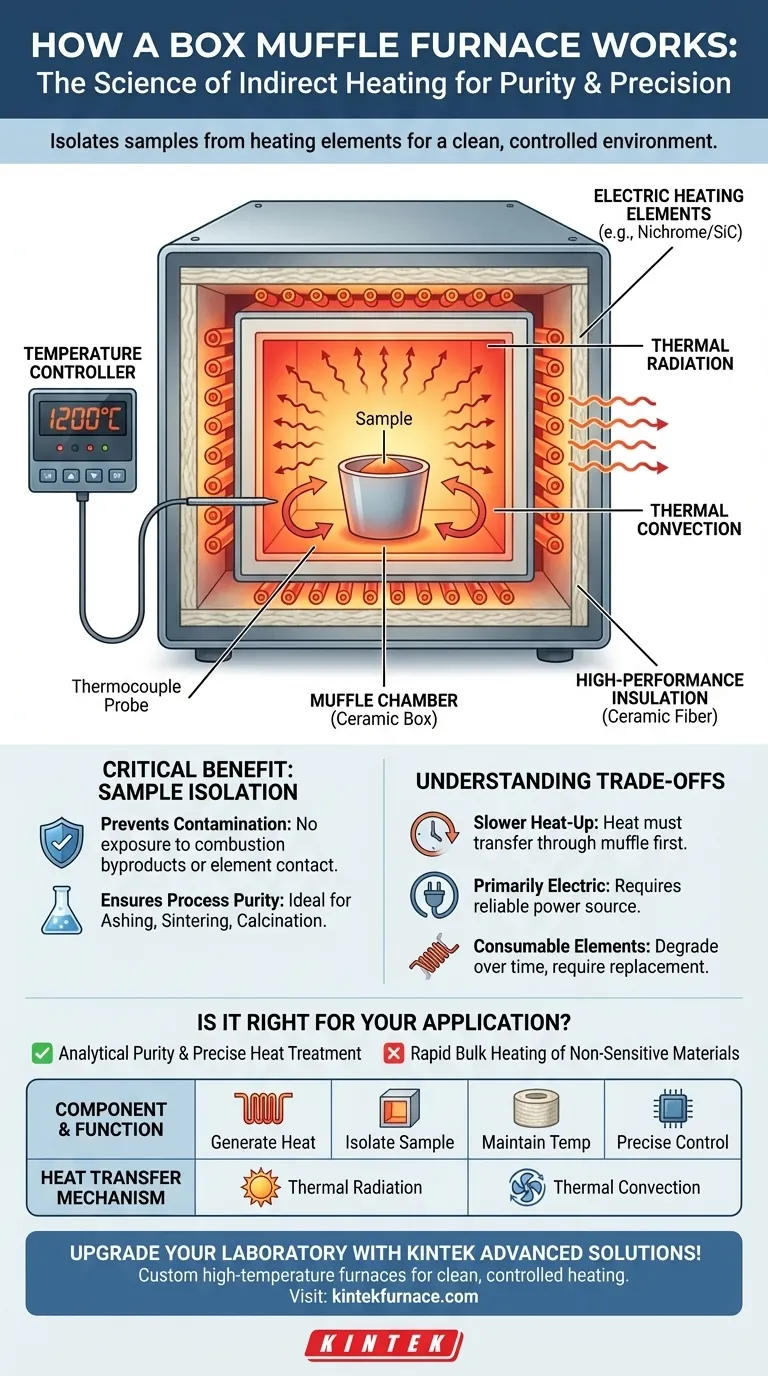

At its core, a box muffle furnace works by indirect heating. Electric heating elements heat the air and walls of an internal chamber, which then transfers that heat to the sample inside through radiation and convection. This design intentionally isolates the material being heated from the raw heating elements, ensuring a clean and highly controlled environment.

The defining principle of a muffle furnace is not just about reaching high temperatures, but about doing so in a completely isolated chamber. This "muffle" design prevents any contamination from fuel, gas byproducts, or the heating elements themselves, which is critical for sensitive analytical or material processes.

The Anatomy of the Heating Process

To understand how a muffle furnace operates, it’s best to break it down into its core components and their specific functions.

The Electric Heating Elements

The process begins with the heating elements, which are typically high-resistance wires or rods made from materials like nichrome or silicon carbide.

When a strong electrical current flows through these elements, their natural resistance causes them to become extremely hot, generating the thermal energy needed for the furnace.

The "Muffle" Chamber

This is the key to the furnace's design. The heating elements do not sit in the same space as the sample. Instead, they line the walls of the main furnace body.

Inside this body is a separate, enclosed chamber—the muffle. This box, often made of a durable ceramic, is where you place your sample. The elements heat the muffle, and the muffle then heats the sample.

High-Performance Insulation

Surrounding the entire heating assembly is a thick layer of ceramic fiber insulation. This material is crucial for preventing heat from escaping into the lab.

This robust insulation is what allows the furnace to reach and maintain very high temperatures (up to 1200°C or higher) efficiently and provides a stable, uniform thermal environment.

The Temperature Controller

A digital or analog controller acts as the brain of the furnace. It uses a thermocouple probe to measure the internal temperature and cycles the power to the heating elements on and off.

This allows for precise temperature control, enabling users to program specific heating rates, dwell times, and cooling profiles required for their experiment.

The Two Modes of Heat Transfer

The muffle design uses a combination of two fundamental heat transfer principles to warm the sample evenly.

Thermal Radiation

As the inner walls of the muffle chamber heat up, they radiate thermal energy directly onto the sample. This is the same principle you feel when standing near a hot fire. This direct line-of-sight energy transfer is a powerful and efficient way to heat the material.

Thermal Convection

Simultaneously, the air trapped inside the sealed muffle chamber is heated by the hot walls. This hot air circulates, transferring heat to all surfaces of the sample, including those not in the direct line of sight of the walls. This process is known as thermal convection.

The combination of radiation and convection ensures that the sample is heated uniformly from all sides, which is essential for repeatable and accurate results.

The Critical Benefit: Sample Isolation

The entire purpose of the muffle design is to create a pristine processing environment.

Preventing Contamination

By placing the sample inside an isolated chamber, it is never exposed to byproducts of combustion (as in a gas furnace) or direct contact with the electric heating elements.

This prevents any foreign materials from contaminating the sample, which is non-negotiable for sensitive applications.

Ensuring Process Purity

Processes like ashing (burning off organic material to measure inorganic residue), sintering (fusing powders together), or calcination (heating to drive off volatile substances) demand absolute purity. The muffle furnace's indirect heating method guarantees that the only changes to the sample are from the heat itself.

Understanding the Trade-offs

While highly effective, the muffle furnace design has practical implications to consider.

Slower Heat-Up Times

Because the heat must first transfer to the muffle chamber before it reaches the sample, the overall heat-up time can be slower compared to a furnace with direct heating.

Primarily Electric Operation

The vast majority of muffle furnaces are electrically powered. This provides clean heat but may be a constraint in areas with high electricity costs or for applications where gas-fired equipment is preferred.

Consumable Heating Elements

The heating elements operate under extreme thermal stress. Over time, they will degrade and eventually fail, requiring replacement as part of regular maintenance.

Is a Muffle Furnace Right for Your Application?

Choosing the right furnace depends entirely on your primary goal.

- If your primary focus is analytical purity (e.g., ashing, trace metal analysis): The muffle furnace is the correct choice, as its isolated chamber is essential for preventing sample contamination.

- If your primary focus is precise material heat treatment (e.g., annealing, hardening): This furnace is an excellent option for its uniform heating and programmable control in a clean atmosphere.

- If your primary focus is extremely rapid heating of non-sensitive bulk materials: You might consider a direct-fired furnace, but you will sacrifice the clean environment and precise control of the muffle design.

Ultimately, the box muffle furnace is the standard for applications where temperature precision and sample purity are paramount.

Summary Table:

| Component | Function |

|---|---|

| Electric Heating Elements | Generate heat via electrical resistance |

| Muffle Chamber | Isolates sample to prevent contamination |

| Insulation | Maintains high temperatures efficiently |

| Temperature Controller | Provides precise control and programming |

| Heat Transfer | Mechanism |

| Thermal Radiation | Direct energy transfer from hot walls |

| Thermal Convection | Circulating hot air ensures uniform heating |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for clean, controlled heating. Contact us today to discuss how our furnaces can enhance your lab's efficiency and purity!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals