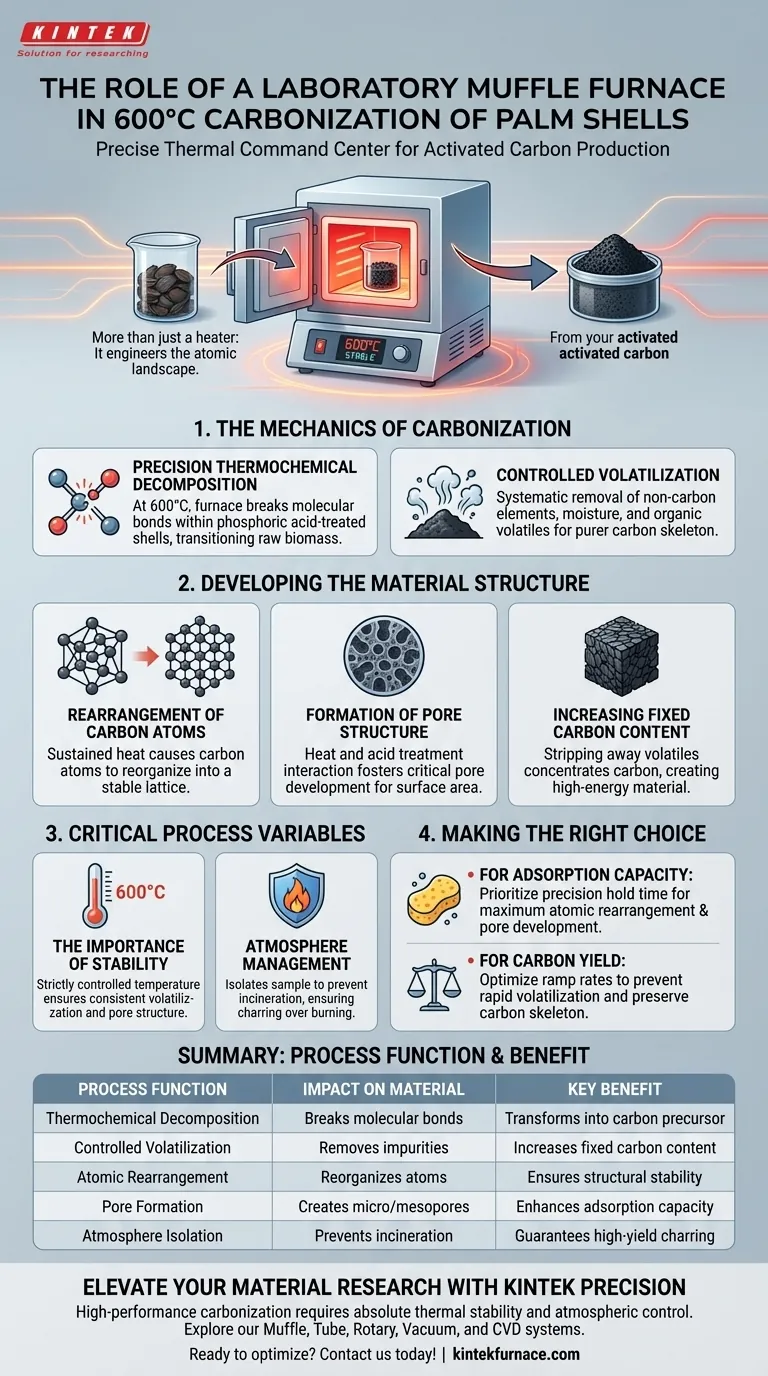

A laboratory muffle furnace acts as the precise thermal command center for converting phosphoric acid-treated palm shells into activated carbon. It provides a strictly controlled, high-temperature environment at 600°C, which is essential for driving thermochemical decomposition, removing impurities, and structurally rearranging carbon atoms to create a porous material.

The muffle furnace is not just a heater; it is the instrument of structural transformation. Its ability to maintain a stable 600°C environment ensures the efficient volatilization of non-carbon elements, directly resulting in the high fixed carbon content and specific pore architecture required for effective activated carbon.

The Mechanics of Carbonization

To understand the furnace's role, we must look beyond simple heating. You are essentially using the furnace to engineer the atomic landscape of the palm shells.

Precision Thermochemical Decomposition

The primary function of the furnace is to facilitate thermochemical decomposition.

At 600°C, the furnace breaks the molecular bonds within the phosphoric acid-treated palm shells. This breakdown is the fundamental step that transitions the material from raw biomass into a carbonized precursor.

Controlled Volatilization

During this phase, the furnace environment allows for the systematic removal of unwanted elements.

Non-carbon components, moisture, and organic volatiles are evaporated and expelled from the material. This leaves behind a purer carbon skeleton, significantly reducing the mass while increasing the quality of the remaining structure.

Developing the Material Structure

The "Deep Need" in this process is creating a material that is highly porous and stable. The muffle furnace drives the physical changes necessary to achieve this.

Rearrangement of Carbon Atoms

Heat alone is not enough; sustained, stable heat causes the carbon atoms to reorganize.

The furnace ensures that as non-carbon elements leave, the remaining carbon atoms rearrange themselves into a more stable lattice. This atomic shifting is the core process that differentiates simple burnt wood from industrial-grade carbon.

Formation of Pore Structure

The interaction between the heat and the phosphoric acid treatment occurs within the furnace chamber.

This environment fosters the development of a basic pore structure. These pores are critical, as they determine the surface area and adsorption capacity of the final activated carbon product.

Increasing Fixed Carbon Content

By stripping away volatiles, the furnace concentrates the carbon.

The result is a material with a significantly higher fixed carbon content compared to the raw palm shells. This high carbon density is the defining characteristic of high-energy or high-adsorption materials.

Critical Process Variables

While the muffle furnace is a robust tool, understanding its operational limits is vital for consistency.

The Importance of Stability

The term "strictly controlled" is the most critical variable in your reference data.

If the furnace cannot maintain a precise 600°C, the decomposition becomes uneven. Fluctuations can lead to incomplete volatilization or inconsistencies in the pore structure, rendering the activated carbon less effective.

Atmosphere Management

While the primary focus is temperature, the "muffle" aspect implies isolation from direct fuel combustion and often control over the internal atmosphere.

Uncontrolled air exposure at these temperatures can lead to incineration (turning the sample to ash) rather than carbonization. The furnace safeguards the sample to ensure it chars rather than burns.

Making the Right Choice for Your Goal

When utilizing a muffle furnace for palm shell carbonization, your operational focus should shift based on your desired outcome.

- If your primary focus is Adsorption Capacity: Prioritize the precision of the temperature hold time to ensure complete carbon atom rearrangement and maximum pore development.

- If your primary focus is Carbon Yield: Ensure the furnace ramp rates are optimized to prevent rapid volatilization that might destroy the carbon skeleton alongside the impurities.

Ultimately, the muffle furnace determines the difference between burning biomass and engineering a high-performance carbon material.

Summary Table:

| Process Function | Impact on Material | Key Benefit |

|---|---|---|

| Thermochemical Decomposition | Breaks molecular bonds in biomass | Transforms raw material into carbon precursor |

| Controlled Volatilization | Removes moisture and organic volatiles | Increases fixed carbon content and purity |

| Atomic Rearrangement | Reorganizes carbon atoms into a lattice | Ensures structural stability and material density |

| Pore Formation | Creates micro/mesoporous architecture | Enhances adsorption capacity and surface area |

| Atmosphere Isolation | Prevents sample incineration/ashing | Guarantees high-yield charring over burning |

Elevate Your Material Research with KINTEK Precision

High-performance carbonization requires more than just heat; it requires the absolute thermal stability and atmospheric control found in KINTEK laboratory solutions.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet the rigorous demands of your high-temperature protocols. Whether you are engineering activated carbon or advanced ceramics, our furnaces provide the precision needed for consistent, repeatable results.

Ready to optimize your carbonization process? Contact us today to discuss your unique needs with our technical team!

Visual Guide

References

- M. I. Atapia, D. Ajir. Characterization and Adsorption of Pb2+and Cu2+ from Aqueous Solution using Activated Carbon from Palm Kernel Shell. DOI: 10.4314/jasem.v29i7.12

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How is a laboratory high-temperature muffle furnace utilized in g-C3N4 synthesis? Optimize Your Thermal Polycondensation

- What is the primary function of a high-temperature muffle furnace in graphene oxide synthesis? Maximize Carbon Yield

- What should homeowners consider when switching to an electric furnace? Avoid Costly Mistakes with This Guide

- What is the function of a high-temperature muffle furnace in the columbite precursor method? Pure Perovskite Synthesis

- How does the muffle furnace ensure uniform heating? Achieve Precise, Even Heat for Your Lab

- What are some major industrial applications of a muffle furnace? Unlock Precision Heating for Your Industry

- How does high-quality insulation benefit a muffle furnace? Boost Efficiency, Safety, and Precision

- What is the function of a Muffle Furnace in the production of cristobalite alpha silica nanoparticles? Precision 900°C Annealing