In short, high-quality insulation is the critical feature that enables a muffle furnace to be efficient, safe, and precise. By effectively trapping heat within the chamber, superior insulation minimizes energy waste, protects users from extreme external temperatures, and ensures the stable, uniform heating required for reliable scientific and industrial processes.

The quality of a muffle furnace's insulation is not merely a feature; it is the foundation of its performance. It directly determines its energy efficiency, operational safety, and the accuracy of its thermal processing.

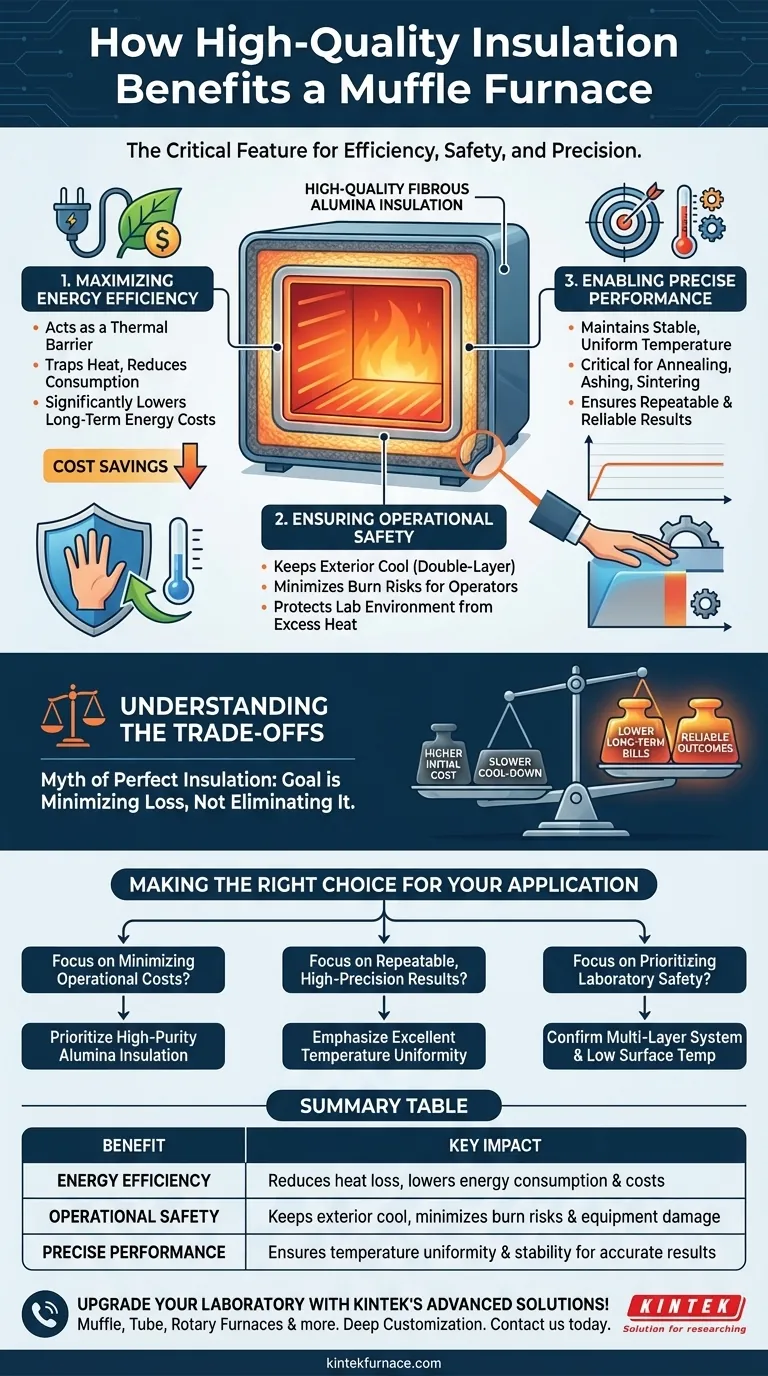

The Core Functions of High-Quality Insulation

A muffle furnace is designed to achieve and maintain extremely high temperatures in a controlled environment. The insulation system is the silent workhorse that makes this possible, serving three primary functions.

Maximizing Energy Efficiency

High-quality insulation, often made from high-purity fibrous alumina, acts as a highly effective thermal barrier. It prevents heat from escaping the internal chamber.

This heat retention directly translates to lower energy consumption. The furnace does not have to work as hard to maintain its setpoint, resulting in significant cost savings over the equipment's lifespan.

Ensuring Operational Safety

Without effective insulation, the exterior of a furnace operating at 1000°C or more would become dangerously hot. This poses a severe burn risk to operators and can damage nearby sensitive equipment.

Superior insulation, often combined with a double-layer steel body and a cooling fan, ensures the outer surface remains at a safe temperature. This drastically reduces the risk of accidents and prevents the furnace from undesirably raising the ambient temperature of the laboratory.

Enabling Precise Performance

Scientific processes like annealing, ashing, and sintering demand exceptional temperature stability. Temperature uniformity, or the even distribution of heat, is critical for achieving repeatable results.

By minimizing heat loss, high-quality insulation helps the furnace maintain a highly stable and uniform thermal environment. This allows for the precise temperature control necessary for sensitive applications where even minor fluctuations can compromise the outcome.

Understanding the Trade-offs

While essential, the choice of insulation involves balancing competing priorities. Understanding these trade-offs is key to selecting the right equipment.

The Myth of Perfect Insulation

No insulation is 100% efficient. All furnaces lose some heat to the surrounding environment. The goal of high-quality insulation is to minimize this loss, not eliminate it entirely. The difference between standard and premium insulation is the rate of that loss.

Insulation Quality vs. Initial Cost

Furnaces with superior insulation materials like high-purity alumina typically have a higher upfront cost. However, this initial investment is often recouped through lower long-term energy bills and the value of more reliable process outcomes.

Impact on Cool-Down Times

A furnace that is excellent at retaining heat is, by design, slow to cool down. While this is a sign of effective insulation, it can be a drawback in high-throughput environments where rapid cycling between batches is required.

Making the Right Choice for Your Application

The ideal insulation depends entirely on your primary goal. Use these points to guide your evaluation of a muffle furnace.

- If your primary focus is minimizing operational costs: Prioritize a furnace with documented high-purity fibrous alumina insulation for the best long-term energy efficiency.

- If your primary focus is ensuring repeatable, high-precision results: Look for systems that emphasize excellent temperature uniformity and stability, as this is a direct outcome of superior insulation.

- If your primary focus is prioritizing laboratory safety: Confirm the furnace has a multi-layered insulation system and a low external surface temperature during peak operation.

Ultimately, viewing insulation as the engine of performance, rather than just a feature, is the key to understanding the true value of a muffle furnace.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Energy Efficiency | Reduces heat loss, lowers energy consumption and costs |

| Operational Safety | Keeps exterior cool, minimizes burn risks and equipment damage |

| Precise Performance | Ensures temperature uniformity and stability for accurate results |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, delivering enhanced efficiency, safety, and performance. Contact us today to discuss how we can support your specific requirements and drive your success!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating