At its core, switching to an electric furnace requires you to evaluate four key areas: the true operational cost based on your local electricity rates, the suitability of the technology for your climate, your home's existing electrical and ductwork infrastructure, and the total upfront investment. The choice is less about the furnace in isolation and more about how it fits into your home's specific ecosystem.

The most critical decision is not simply "electric vs. gas," but which type of electric heating to adopt. Understanding the profound difference between a highly-efficient heat pump and a standard electric resistance furnace is the key to ensuring your switch is a financial success, not a costly mistake.

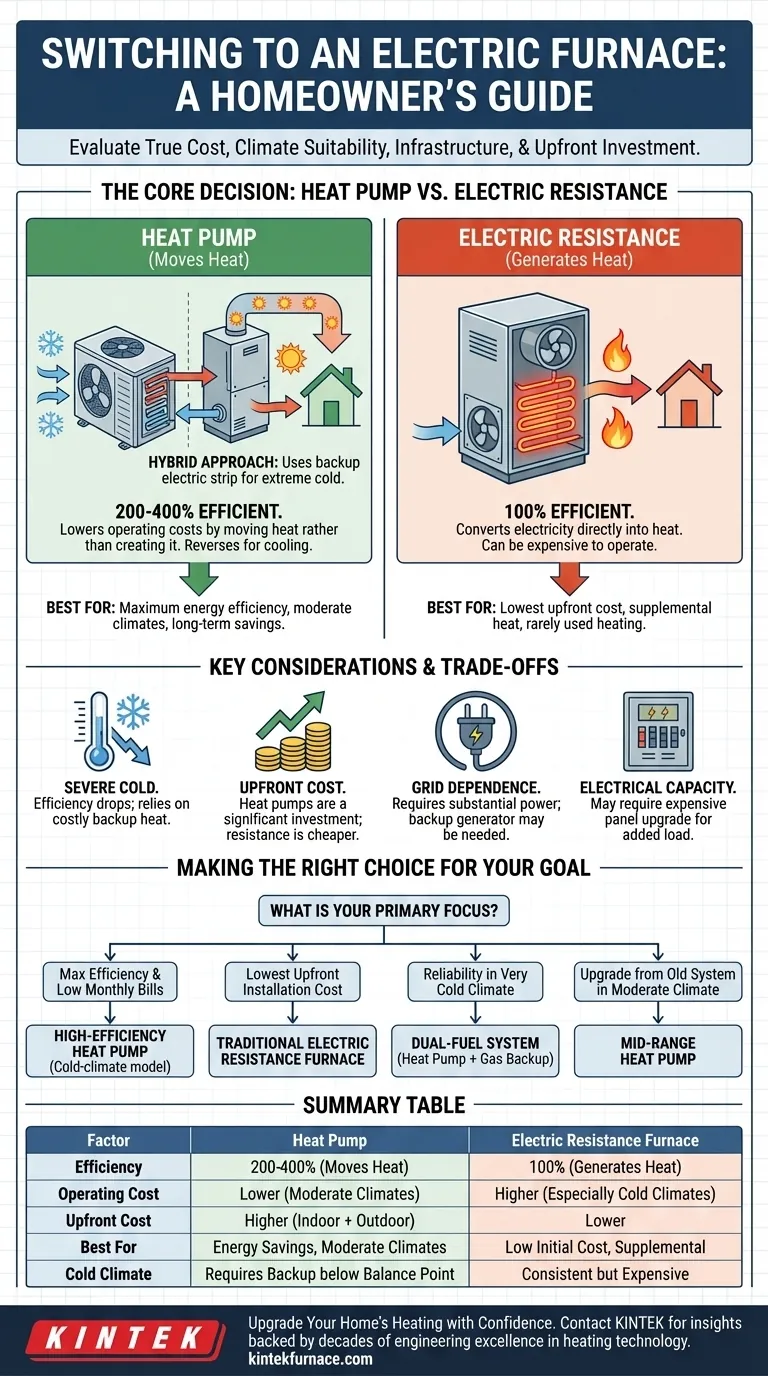

The Primary Decision: Heat Pump vs. Electric Resistance

Before looking at any specific model, you must understand the two fundamentally different ways to heat a home with electricity. This choice has the single biggest impact on your comfort and your monthly bills.

How Electric Resistance Furnaces Work

An electric resistance furnace operates much like a giant toaster or a space heater. It uses heating elements—large coils that glow hot when electricity passes through them—to generate heat directly.

A fan then blows air over these hot coils and distributes the warmed air throughout your home via the ductwork. This method is 100% efficient at converting electricity into heat, which sounds impressive, but it is often the most expensive way to heat a home.

How Heat Pumps Work

A heat pump doesn't create heat; it moves heat. In winter, it extracts heat from the outside air (even when it's cold) and transfers it inside. In summer, it reverses the process, extracting heat from your indoor air and moving it outside, functioning exactly like an air conditioner.

Because it's moving heat rather than generating it from scratch, a modern heat pump can be 200% to 400% efficient. For every one unit of electricity it consumes, it can deliver two to four units of heat, making it dramatically cheaper to operate than an electric resistance furnace.

The Hybrid Approach: A Heat Pump with Backup Heat

Most heat pump systems are installed with a backup heat source, known as an auxiliary or emergency heat strip. This is simply a small electric resistance heating element inside the air handler.

When the outdoor temperature drops so low that the heat pump can no longer extract enough heat efficiently (a point called the "balance point"), the system automatically engages the resistance strips to supplement the heat. This gives you the incredible efficiency of a heat pump for most of the year and the reliability of resistance heat for the coldest days.

Understanding the Trade-offs

Switching to electric heating is a significant upgrade, but it comes with specific challenges and costs you must consider objectively.

The Challenge of Severe Cold

A heat pump's efficiency decreases as the outdoor temperature falls. In regions with prolonged, deep freezes, the system will rely more heavily on its less-efficient backup resistance heat, driving up electricity costs.

The Upfront Installation Cost

A standard electric resistance furnace is one of the least expensive types of central heating systems to purchase and install. A heat pump system, which includes both an indoor and an outdoor unit, is a more significant upfront investment, often costing thousands of dollars more.

Dependence on the Electrical Grid

If you live in an area prone to power outages during winter storms, an all-electric system leaves you without heat. Unlike a gas furnace that might only need a small amount of electricity to run its fan and controls, an electric furnace or heat pump requires substantial power. This makes a backup power source, like a generator, a more critical consideration.

Your Home's Electrical Capacity

An electric resistance furnace, or even the backup heat strips in a heat pump, draws a large amount of electrical current. You must have a professional confirm that your home's electrical panel has both the physical space for new double-pole breakers and the total amperage capacity to handle the added load safely. An expensive panel upgrade may be required.

Making the Right Choice for Your Goal

Your ideal solution depends entirely on your priorities. Use this guide to determine your best path forward.

- If your primary focus is maximum energy efficiency and the lowest monthly bills: A high-efficiency, cold-climate heat pump is the undeniable winner, offering significant long-term savings that offset its higher upfront cost.

- If your primary focus is the lowest possible upfront installation cost: A traditional electric resistance furnace is the cheapest option to purchase, but be prepared for potentially very high heating bills, especially in a cold climate.

- If your primary focus is reliability in a very cold climate: A "dual-fuel" system, which pairs an electric heat pump with a gas furnace for backup, provides the best of all worlds—efficiency in milder weather and powerful, cost-effective gas heat in deep freezes.

- If your primary focus is upgrading from an old, inefficient system in a moderate climate: A mid-range heat pump offers an excellent balance of upfront cost, high efficiency, and the added benefit of providing central air conditioning.

Ultimately, choosing the right electric heating system is a long-term investment in your home's comfort and financial health.

Summary Table:

| Factor | Heat Pump | Electric Resistance Furnace |

|---|---|---|

| Efficiency | 200-400% (moves heat) | 100% (generates heat) |

| Operating Cost | Lower in moderate climates | Higher, especially in cold climates |

| Upfront Cost | Higher (indoor + outdoor unit) | Lower |

| Best For | Energy savings, moderate climates | Low initial cost, supplemental heat |

| Cold Climate Performance | Requires backup heat below balance point | Consistent but expensive in severe cold |

Upgrade Your Home's Heating with Confidence

Choosing the right heating system is a major decision that impacts your comfort and finances for years to come. At KINTEK, we understand that every home is unique. While we specialize in advanced high-temperature solutions for laboratories, our expertise in thermal systems translates to a deep understanding of efficiency, reliability, and precision temperature control.

Whether you're a homeowner evaluating a heat pump or a professional specifying equipment for a demanding application, the principles of smart thermal management are universal. Let's discuss your specific needs. Contact our team today for insights backed by decades of engineering excellence in heating technology.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability