A muffle furnace facilitates the reduction of graphene oxide (GO) by providing a precisely controlled thermal environment combined with a specific protective atmosphere. For hydrazine vapor thermal reduction, the optimal process conditions involve maintaining a steady temperature of 150°C for one hour under a nitrogen protective atmosphere.

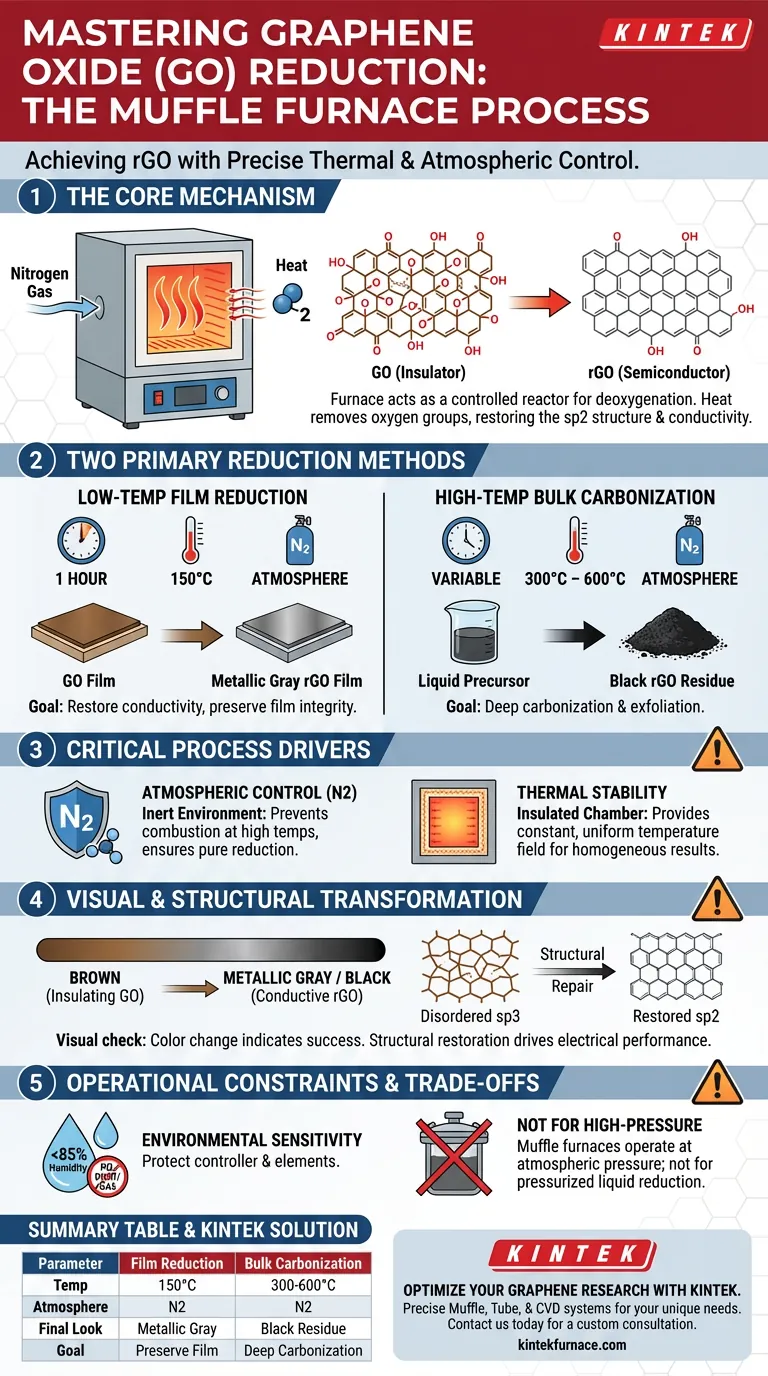

The Core Mechanism The muffle furnace acts as a controlled reactor that drives the decomposition of oxygen-containing functional groups. By stabilizing the thermal and atmospheric conditions, it allows for the restoration of the conjugated carbon structure, effectively transforming the material from an electrical insulator into a conductive semiconductor.

Controlled Thermal Environments

Low-Temperature Reduction for Films

According to the primary methodology for hydrazine vapor thermal reduction, the muffle furnace is set to a moderate temperature of 150°C.

This temperature is maintained for one hour. This specific window is sufficient to promote the chemical changes required for thin films without degrading the underlying substrate or structure.

High-Temperature Carbonization

For more aggressive processing, such as reducing citric acid-ethanolamine complexes, the muffle furnace can operate between 300°C and 600°C.

At the upper limit of 600°C, the furnace induces deep carbonization. This facilitates the complete transformation and exfoliation of liquid precursors into multi-layered rGO black residue.

Atmospheric Control and Insulation

The Role of Protective Atmospheres

A standard muffle furnace alone introduces heat, but for GO reduction, it must be paired with a nitrogen protective atmosphere.

This inert environment is critical. It prevents the carbon material from burning off (oxidizing) at high temperatures and ensures the chemical reaction is strictly reduction, not combustion.

Thermal Stability and Efficiency

Muffle furnaces are designed with well-insulated chambers to minimize energy loss.

This insulation ensures rapid heating and recovery. It provides a constant, uniform temperature field, which is essential for ensuring the reduction is homogeneous across the entire sample.

Material Transformation and Indicators

Restoration of Structure

The heat provided by the furnace drives the removal of oxygen groups.

This process repairs the sp2 hybridized structure of the carbon lattice. This structural restoration is the primary driver for the significant improvement in electrical performance.

Visual Verification

You can visually verify the success of the process conditions by observing the color change of the material.

Under the 150°C process, a GO film will transform from brown (insulating state) to metallic gray (conductive rGO state). Higher temperature processes may yield a black residue.

Operational Trade-offs and Constraints

Environmental Sensitivity

While robust, the muffle furnace requires a controlled external environment to function correctly.

The relative humidity in the lab must not exceed 85%. Furthermore, the area must be free of conductive dust, explosive gases, or corrosive gases to protect the controller and heating elements.

Comparison to High-Pressure Methods

It is important to distinguish the muffle furnace from high-pressure closed reaction vessels.

If your process requires liquid-phase reduction with agents like sodium borohydride at elevated pressures, a muffle furnace is not the correct tool. Muffle furnaces operate at atmospheric pressure; high-pressure chemical reductions require sealed vessels to maintain stable pressure fields at lower temperatures (e.g., 90°C).

Making the Right Choice for Your Goal

The specific settings you choose for your muffle furnace depend heavily on the physical form of your precursor and the desired end-product.

- If your primary focus is reducing GO films: Use a 150°C cycle for one hour under nitrogen to restore conductivity while preserving film integrity.

- If your primary focus is creating bulk rGO powder: Utilize higher temperatures (300°C–600°C) to induce deep carbonization and exfoliation of precursor complexes.

- If your primary focus is equipment longevity: Ensure the operating environment is dry (<85% humidity) and free of corrosive gases to prevent controller failure.

Select your temperature profile based on whether you need delicate film restoration or aggressive bulk carbonization.

Summary Table:

| Process Parameter | GO Film Reduction (Hydrazine) | Bulk rGO Carbonization |

|---|---|---|

| Temperature | 150°C | 300°C – 600°C |

| Duration | 1 Hour | Variable (based on precursor) |

| Atmosphere | Nitrogen (Protective) | Nitrogen (Protective) |

| Final Appearance | Metallic Gray | Black Residue |

| Core Goal | Preserve film & conductivity | Deep carbonization & exfoliation |

Optimize Your Graphene Research with KINTEK

Precise atmospheric control and uniform heating are the foundations of successful Graphene Oxide reduction. KINTEK provides high-performance laboratory solutions tailored to these exacting needs. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique material science requirements.

Whether you are restoring thin-film conductivity or producing bulk rGO powder, our furnaces ensure the thermal stability your research demands.

Ready to upgrade your lab's capabilities?

Contact KINTEK today for a custom consultation.

Visual Guide

References

- Amal Elsokary, Marwa Karim. Fabrication of composite transparent conductive electrodes based on silver nanowires. DOI: 10.1038/s41598-024-53286-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the applications of muffle furnaces? Essential for High-Temperature Material Processing

- What materials should be avoided when using a muffle furnace? Prevent Hazards and Extend Equipment Life

- How do electric furnaces support environmental sustainability? Achieve Zero On-Site Emissions & Green Manufacturing

- What is the role of a laboratory muffle furnace in the oxidative annealing of black indium oxide particles?

- What role does a muffle furnace play in LDH-derived catalysts? Unlock High-Performance Catalyst Synthesis

- Why is a muffle furnace considered a sensitive product? Understand the High-Risk Hazards and Safety Needs

- Why is atmosphere control important in a Muffle furnace, and what types of atmospheres can be used?

- What options are available for temperature uniformity in Box Furnaces? Achieve Precise Heat for Your Critical Processes