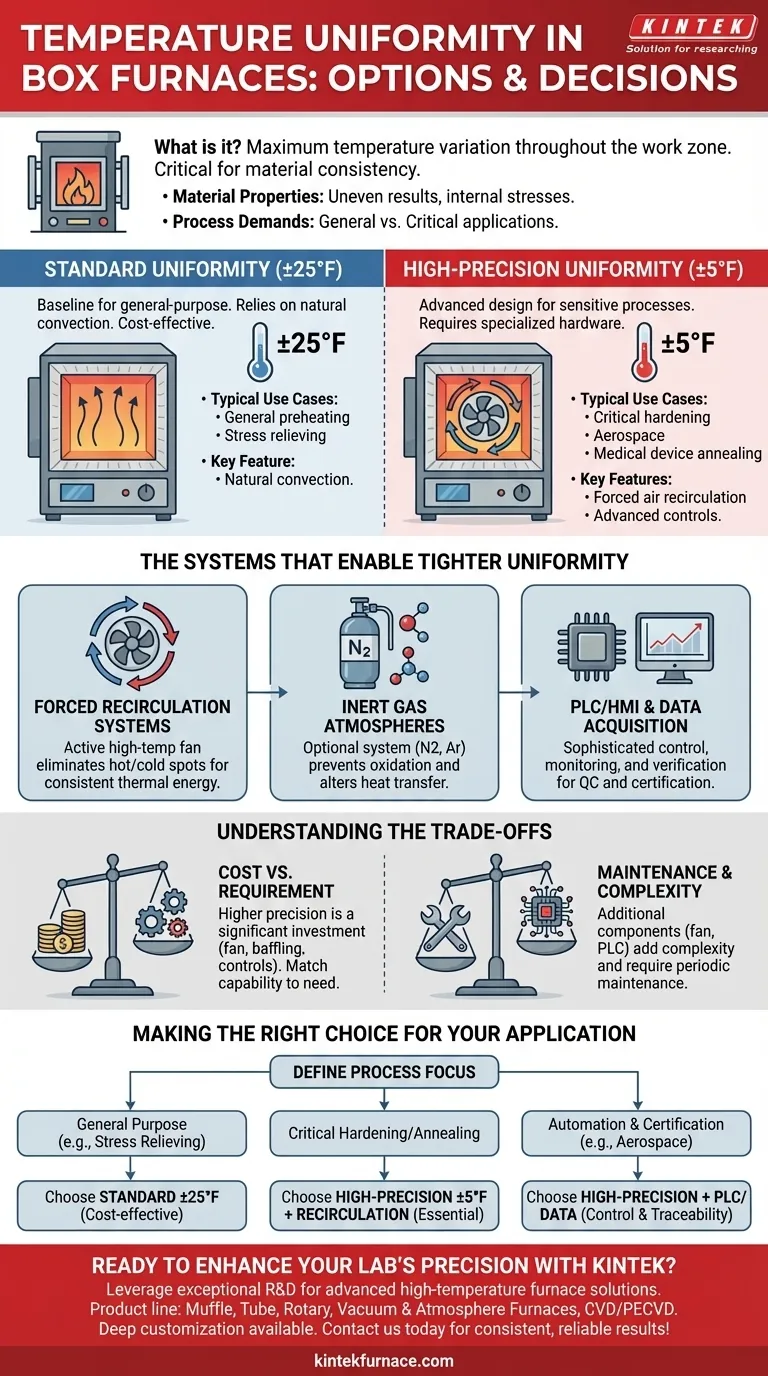

The primary options for temperature uniformity in a box furnace are a standard tolerance of ±25°F and a high-precision option of ±5°F. The choice between these levels is not merely a setting, but a fundamental decision about the furnace's design, as achieving tighter uniformity often requires specialized hardware to ensure consistent heat distribution.

Choosing the correct temperature uniformity is a critical engineering decision driven by your specific thermal process. Tighter uniformity is achieved not by a simple adjustment, but through integrated systems, most notably forced air recirculation, that actively manage heat within the furnace chamber.

Why Temperature Uniformity is Critical

Temperature uniformity refers to the maximum temperature variation that exists throughout a defined volume of the furnace chamber, known as the work zone. For processes like hardening, annealing, or stress relieving, this consistency is paramount.

The Impact on Material Properties

Even minor temperature deviations across a part can lead to inconsistent results. This may manifest as uneven hardness, internal stresses, or variations in grain structure, compromising the quality and performance of the final product.

The Demands of Different Processes

Processes like general preheating may tolerate a wider temperature window. In contrast, critical applications such as aerospace component tempering or medical device annealing demand extremely precise and uniform heat to meet stringent specifications.

Understanding the Uniformity Options

The available uniformity levels represent two distinct tiers of furnace performance, each suited for different applications.

The Standard: ±25°F

This is the baseline for most general-purpose box furnaces. It is achieved through the strategic placement of heating elements that rely on natural convection and radiation to heat the workload. This level is cost-effective and sufficient for many heat-treating tasks.

The High-Precision Option: ±5°F

Achieving this level of precision requires a more advanced furnace design. It is essential for sensitive materials and processes where the metallurgical outcome is directly tied to exact temperature control. This is not just a feature but a system-level capability.

The Systems That Enable Tighter Uniformity

Obtaining high-precision uniformity is an active process that relies on optional mechanical and control systems working together.

Forced Recirculation Systems

This is the most critical component for achieving tight uniformity. A high-temperature fan actively circulates the heated air within the chamber, eliminating the hot and cold spots that naturally occur with passive convection. This forced movement ensures all surfaces of the workload receive consistent thermal energy.

Inert Gas Atmospheres

While primarily used to prevent oxidation, an optional inert gas system (using nitrogen or argon) also changes the heat transfer characteristics inside the furnace. This must be accounted for when designing for high uniformity.

PLC/HMI and Data Acquisition

Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) allow for more sophisticated control over heating elements and cycle times. Paired with data acquisition systems, they can monitor temperatures in multiple locations to verify that uniformity is maintained throughout the process, providing essential data for quality control and certification.

Understanding the Trade-offs

Selecting a higher level of temperature uniformity involves balancing performance requirements with practical considerations.

Cost vs. Process Requirement

A furnace equipped for ±5°F uniformity is a more significant investment. The additional cost comes from the recirculation fan, internal baffling, and more advanced control systems. It is crucial to match the furnace's capability to the actual needs of your process to avoid over-specification.

Maintenance and Complexity

A recirculation fan and advanced PLC controls are additional components that add complexity and require periodic maintenance. This should be factored into the total cost of ownership.

Making the Right Choice for Your Application

Your decision should be guided by the specific requirements of your thermal process and quality standards.

- If your primary focus is general-purpose stress relieving or preheating: The standard ±25°F uniformity is typically sufficient and the most cost-effective solution.

- If your primary focus is critical hardening, tempering, or annealing: Investing in the ±5°F option with a recirculation system is essential to guarantee consistent and repeatable metallurgical properties.

- If your primary focus is process automation and certification (e.g., aerospace): Combining high-precision uniformity with a PLC/HMI and data acquisition provides the control and traceability required to meet industry standards.

Ultimately, selecting the right temperature uniformity is about aligning the furnace's engineering with the precise needs of your material and the quality standards of your final product.

Summary Table:

| Uniformity Option | Typical Use Cases | Key Features |

|---|---|---|

| ±25°F Standard | General preheating, stress relieving | Cost-effective, relies on natural convection |

| ±5°F High-Precision | Critical hardening, aerospace, medical device annealing | Forced air recirculation, advanced controls |

Ready to enhance your lab's thermal processing with precision? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you need standard or high-precision temperature uniformity, we can help you achieve consistent, reliable results. Contact us today to discuss how our furnaces can optimize your processes and ensure top-quality outcomes!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure

- How does a laboratory high-temperature box furnace assist in evaluating concrete fire resistance? | KINTEK

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- How is a muffle furnace utilized for AlN crystal post-processing? Optimize Surface Purity via Staged Oxidation