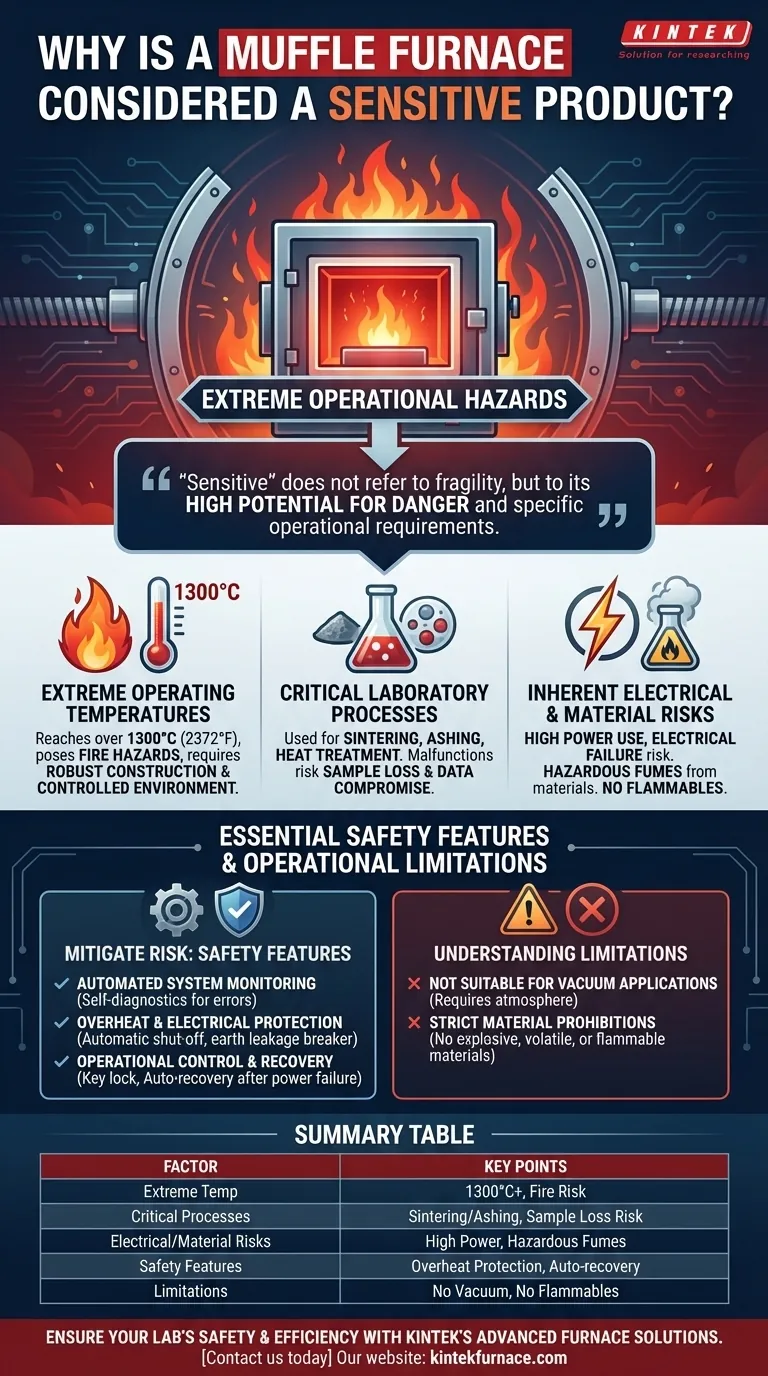

At its core, a muffle furnace is considered a sensitive product due to the extreme operational hazards it presents. Its ability to reach temperatures over 1300°C creates significant risks of fire, severe burns, and electrical failure, demanding stringent safety features and precise user control to prevent accidents in a laboratory or industrial setting.

The term "sensitive" does not refer to the furnace's fragility, but to its high potential for danger and its specific operational requirements. Safe and effective use depends entirely on understanding its risks, limitations, and the critical safety systems designed to manage them.

The Core Reasons for Its "Sensitive" Classification

A muffle furnace's sensitivity is a direct result of its powerful capabilities and the environments where it is used. Three factors are central to this classification.

Extreme Operating Temperatures

The primary reason a muffle furnace is considered sensitive is its intense heat output. Capable of reaching up to 1300°C (2372°F), it operates at temperatures that can easily become a severe fire hazard or cause catastrophic equipment failure if not properly managed.

This level of heat requires specialized insulation, robust construction, and a controlled environment to operate safely.

Criticality of Laboratory Processes

Muffle furnaces are used for a wide range of precise thermal processes, including sintering ceramics, ashing samples for analysis, and the heat treatment of metals.

These applications are often part of critical research or quality control. A furnace malfunction could not only be dangerous but could also destroy valuable samples, compromise data integrity, and waste significant time and resources.

Inherent Electrical and Material Risks

The immense power required to generate such high heat introduces significant electrical risk. Furthermore, heating certain materials can release hazardous fumes or byproducts.

The furnace's design and its surrounding environment must account for these dangers. Flammable or explosive materials must never be placed inside or stored near the unit.

Essential Safety Features to Mitigate Risk

Because of these inherent sensitivities, a modern muffle furnace is not just a simple heating box. It is an engineered system with multiple layers of protection designed to prevent failure and ensure operator safety.

Automated System Monitoring

A reliable furnace includes self-diagnostic functions that act as a nervous system, constantly checking for internal faults.

These diagnostics typically monitor for sensor errors, SSR (Solid State Relay) short circuits, and heater disconnection. If a critical fault is detected, the system can alert the user or shut down automatically to prevent a hazardous situation.

Overheat and Electrical Protection

The most critical safety features are those that prevent runaway heat and electrical faults. An automatic overheat prevention system is non-negotiable, acting as a failsafe to shut off power if the primary temperature controller fails.

Additionally, an earth leakage breaker is essential to protect operators from electrical shock in the event of an electrical fault.

Operational Control and Recovery

Features that ensure proper use and process continuity are also vital. A key lock function prevents unauthorized or accidental changes to critical settings during a run.

Auto-recovery after power failure allows the furnace to resume its heating cycle once power is restored, preserving long-duration experiments and preventing thermal shock to the materials inside.

Understanding Operational Limitations

A key part of its sensitivity is knowing what the furnace cannot do. Using it outside of its intended purpose is a common source of failure and danger.

Not Suitable for Vacuum Applications

A muffle furnace is designed for heating materials in the presence of air (at atmospheric pressure). It is not sealed for vacuum and is entirely unsuitable for processes that require an inert or oxygen-free environment.

For applications like sintering sensitive metals without oxidation, a vacuum furnace is the correct and necessary choice. Attempting to create a vacuum in a muffle furnace is a dangerous misuse of the equipment.

Strict Material Prohibitions

You must never place explosive, volatile, or flammable materials inside a muffle furnace. The extreme temperatures create an obvious risk of fire or explosion.

This sensitivity extends to the surrounding area. The furnace should be installed in a well-ventilated location away from any stored chemicals or combustible materials.

How to Apply This to Your Project

Choosing and operating a muffle furnace requires a clear understanding of your goals and a non-negotiable commitment to safety.

- If your primary focus is operator safety and lab compliance: Prioritize a furnace with a comprehensive suite of certified safety features, especially overheat prevention, self-diagnostics, and an earth leakage breaker.

- If your primary focus is process reliability for critical samples: Look for robust temperature control, calibration offset capabilities, and an auto-recovery function to protect your work from power interruptions.

- If your work involves materials that react with air at high temperatures: Acknowledge that a standard muffle furnace is the wrong tool and investigate specialized vacuum or controlled-atmosphere furnaces instead.

Treating a muffle furnace as a sensitive, high-risk instrument is the first and most important step toward using it safely and achieving reliable results.

Summary Table:

| Factor | Key Points |

|---|---|

| Extreme Operating Temperatures | Reaches over 1300°C, poses fire hazards, requires robust insulation and control |

| Critical Laboratory Processes | Used for sintering, ashing, heat treatment; malfunctions risk sample loss and data compromise |

| Electrical and Material Risks | High power use can cause electrical failure; hazardous fumes from materials require ventilation |

| Essential Safety Features | Includes overheat prevention, self-diagnostics, earth leakage breaker, and auto-recovery |

| Operational Limitations | Not for vacuum applications; prohibits flammable materials to prevent explosions |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide muffle, tube, rotary, vacuum, and atmosphere furnaces, along with CVD/PECVD systems, tailored to your unique experimental needs. Our deep customization capabilities help you mitigate risks and achieve reliable results. Contact us today to discuss how we can support your project with precision and safety!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis