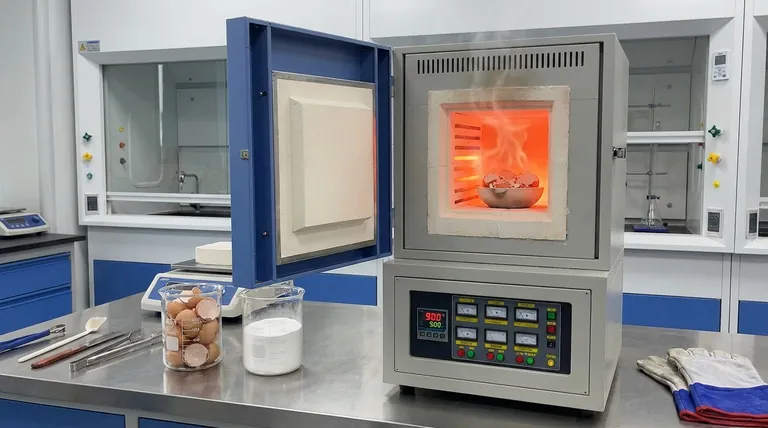

The primary purpose is calcination. At 900°C, the furnace induces thermal decomposition, chemically altering the eggshells from calcium carbonate (CaCO3) into calcium oxide (CaO) by forcibly expelling carbon dioxide. This specific temperature is critical to ensure the complete transformation of the material structure.

The process converts inert waste biomass into a functional resource, generating active CaO nanoparticles specifically optimized for catalytic applications.

The Mechanism of Transformation

Thermal Decomposition

The fundamental reaction occurring at 900°C is thermal decomposition. Raw eggshells consist primarily of calcium carbonate (CaCO3), which is chemically stable at room temperature.

By applying high heat, you overcome the activation energy required to break the chemical bonds. This drives off carbon dioxide (CO2) as a gas, leaving behind calcium oxide (CaO).

Creation of Functional Nanoparticles

This process does more than simply dry the shells; it fundamentally restructures them.

The calcination process effectively transforms the macroscopic shell structure into CaO nanoparticles. This morphological change is essential for increasing surface area and reactivity.

Why 900°C Matters

Ensuring Complete Conversion

Temperature control is the defining factor in product quality.

If the temperature is too low, the core of the material may remain as calcium carbonate. Reaching 900°C ensures the heat penetrates thoroughly to drive the reaction to completion.

Activation for Catalysis

The goal of this process is to create a material suitable for catalytic applications.

Raw eggshells are largely inert. The high-temperature treatment "activates" the material, creating the chemical properties necessary to function as an effective catalyst in subsequent chemical processes.

Understanding the Trade-offs

Energy Intensity vs. Product Value

The primary trade-off in this process is the energy cost relative to the raw material cost.

While eggshells are a low-cost or negative-cost waste product, maintaining a furnace at 900°C requires significant energy input. This expenditure is only justified because the resulting CaO nanoparticles possess high economic value as catalysts, far exceeding the value of the raw biomass.

Making the Right Choice for Your Goal

To maximize the utility of this process, align your parameters with your specific end-use requirements.

- If your primary focus is Waste Management: Ensure the process runs long enough to reduce volume significantly, though high purity may be less critical.

- If your primary focus is Catalyst Production: Strictly monitor the 900°C threshold to guarantee total decomposition of carbonate into active oxide.

Mastering the calcination temperature is the difference between burning waste and engineering a valuable chemical asset.

Summary Table:

| Feature | Process Details |

|---|---|

| Primary Goal | Calcination (Thermal Decomposition) |

| Chemical Change | CaCO3 → CaO + CO2 |

| Target Temperature | 900°C |

| End Product | Active CaO Nanoparticles |

| Primary Application | Catalytic Processes & Material Engineering |

Elevate Your Material Research with KINTEK

Turning waste biomass into high-value catalysts requires precision heat treatment. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, and Vacuum furnaces engineered to maintain the strict 900°C thresholds necessary for complete calcination.

Whether you need a standard solution or a system customized for your unique laboratory needs, our high-temp furnaces provide the thermal stability your research demands.

Ready to optimize your catalytic applications? Contact us today to find your perfect furnace solution!

References

- Nabil A. Alhemiary. Synthesis of Novel Nanocomposite CaO/AC/ZnO from Biogenic Wastes of Date Palm Seeds from The Najran Region (Saudi Arabia) and Eggshells for Degradation of Methylene Blue. DOI: 10.15379/ijmst.v11i1.3625

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the specific role of the atmosphere within a muffle furnace? Ensuring Uniform Heating and Chemical Control

- What is the working principle of a muffle furnace? Master Precise, Contamination-Free Heating

- What design features enhance the durability and performance of a muffle furnace? Boost Lab Efficiency with Robust Design

- Why does the edge of a workpiece reach higher temperatures than its center? Master Thermal Uniformity in Sintering

- Why is wearing appropriate clothing important when operating a benchtop furnace? Essential Safety Tips to Prevent Burns and Fires

- Which industries utilize Box Furnaces? The Essential Tool for Industrial Heat Treatment

- How do temperature controllers and electric heating furnaces facilitate different pyrolysis modes in research systems?

- Why is an industrial high-temperature muffle furnace necessary for preparing metal oxide/honeycomb catalysts?