At its core, a muffle furnace's durability and performance are determined by its ability to manage extreme heat over thousands of cycles. Key design features that achieve this include a chemically resistant ceramic muffle, a robust stainless steel housing, high-efficiency insulation, and a structural design that intelligently accommodates thermal expansion.

The most effective muffle furnaces are not just built with strong materials; they are designed as a complete system. True durability and performance arise from the synergy between a chemically inert inner chamber, an efficient thermal envelope, and a frame engineered to withstand the physical stress of rapid heating and cooling.

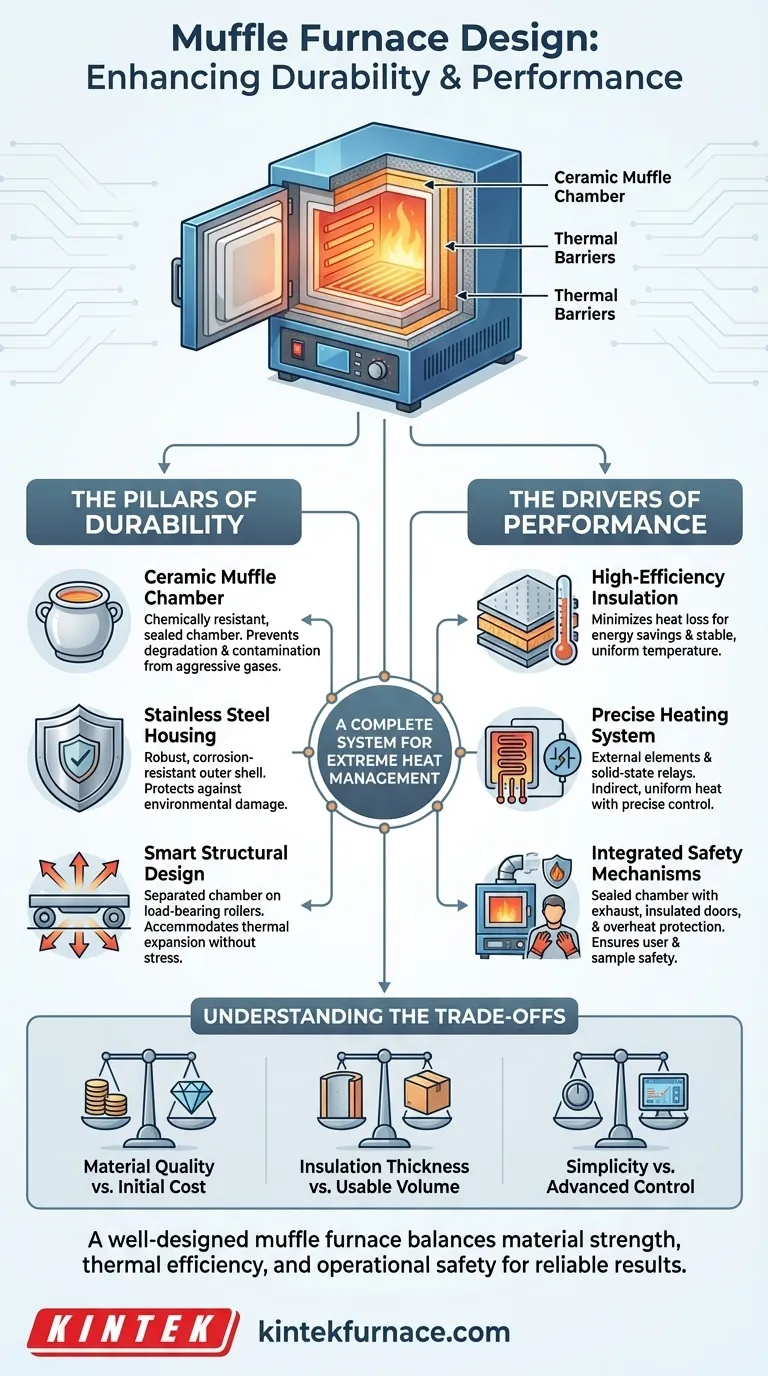

The Pillars of Durability

Durability is a furnace's ability to withstand chemical attack, physical stress, and corrosion over its service life. This is achieved through careful material selection and structural engineering.

The Muffle Chamber: Your First Line of Defense

The muffle itself is an insulated, sealed chamber that isolates the sample from the heating elements. Ceramic muffles are the standard for high-performance applications.

This material choice provides exceptional resistance to the aggressive gases and vapors that can be released during heating processes, preventing both chamber degradation and sample contamination.

The External Housing: Resisting the Environment

The outer body of the furnace is typically constructed from stainless steel. This provides a durable, corrosion-resistant shell that protects the internal components.

A robust housing ensures the furnace maintains its structural integrity even in demanding lab or industrial environments where chemical spills or high humidity may be present.

Structural Design: Managing Thermal Expansion

One of the greatest stresses on a furnace is thermal expansion—the tendency for materials to expand when heated. Sophisticated designs separate the furnace chamber from the main frame.

By placing the chamber on load-bearing rollers or using a step-type assembling structure, the design allows the chamber to expand and contract freely without putting stress on the frame. This prevents cracks and warping, dramatically extending the furnace's lifespan.

The Drivers of Performance

Performance is measured by temperature accuracy, stability, energy efficiency, and user safety. These are driven by the heating and insulation systems.

Insulation: The Key to Efficiency and Stability

High-quality, efficient insulation is critical. It minimizes heat loss to the surrounding environment, which provides two major benefits.

First, it reduces energy consumption, making the furnace more cost-effective to operate. Second, it helps maintain a highly stable and uniform temperature inside the chamber, which is essential for repeatable and accurate results.

The Heating System: Precision and Control

In a muffle furnace, heating elements are placed outside the muffle chamber. This indirect heating method prevents direct contact with the sample, eliminating a source of contamination and allowing for more uniform heat distribution.

The use of solid-state relays for managing power to these elements allows for quiet, precise control over the heating cycle. This is fundamental for processes that require specific temperature ramps and dwell times.

Safety Mechanisms: Protecting the User and the Sample

Modern furnaces incorporate multiple safety features. A sealed muffle chamber with an exhaust system protects the user by safely venting harmful gases generated during heating.

Features like insulated flap doors and adjustable air inlets protect operators from hot surfaces. Additionally, internal safety mechanisms are built in to prevent overheating, ensuring the furnace operates within safe limits at all times.

Understanding the Trade-offs

Selecting a muffle furnace involves balancing competing design priorities. Understanding these trade-offs is key to choosing the right tool for the job.

Material Quality vs. Initial Cost

Higher-grade materials, such as pure alumina ceramics and thicker gauge stainless steel, significantly increase durability and chemical resistance. However, these premium materials come with a higher upfront cost.

Insulation Thickness vs. Usable Volume

More insulation leads to better thermal efficiency and temperature stability. The trade-off is that for a given external footprint, thicker insulation reduces the internal usable chamber volume.

Simplicity vs. Advanced Process Control

A basic furnace with a simple controller is inherently robust and easy to operate. Advanced models with programmable controllers, gas inlets, and exhaust systems offer far greater control and versatility but introduce more complexity and potential points of failure.

Making the Right Choice for Your Application

Your specific goal should guide your evaluation of a furnace's design features.

- If your primary focus is sample purity and process control: Prioritize a furnace with a high-quality sealed ceramic muffle and a precise controller with solid-state relays.

- If your primary focus is longevity in a high-use environment: Look for a robust stainless steel housing and a design that explicitly manages thermal expansion with rollers or a separated frame.

- If your primary focus is operational efficiency and safety: Pay close attention to the quality and thickness of the insulation and ensure the furnace has certified safety features like overheating protection and gas venting.

Ultimately, a well-designed muffle furnace provides reliable results by intelligently balancing material strength, thermal efficiency, and operational safety.

Summary Table:

| Feature | Role in Durability | Role in Performance |

|---|---|---|

| Ceramic Muffle | Resists chemical attack and corrosion | Ensures sample purity and uniform heating |

| Stainless Steel Housing | Protects against physical stress and environmental damage | Maintains structural integrity for safe operation |

| High-Efficiency Insulation | Reduces heat loss and extends lifespan | Improves temperature stability and energy efficiency |

| Thermal Expansion Design | Prevents cracks and warping from stress | Supports consistent performance over cycles |

| Solid-State Relays | Enhances control system longevity | Enables precise temperature ramps and dwell times |

Ready to enhance your lab's capabilities with a durable and high-performance muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can optimize your processes and deliver reliable results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production