By integrating electric heating furnaces with high-precision temperature controllers, researchers can manipulate heating rates to explicitly switch between programmed temperature rise (slow pyrolysis) and isothermal feeding (fast pyrolysis). The controller’s feedback mechanism regulates the furnace's power output to strictly adhere to these specific thermal profiles, which is the defining variable in pyrolysis experimentation.

The ability to precisely simulate distinct heating rates is the foundation of pyrolysis research. By controlling the thermal environment, you directly influence the reaction kinetics, altering the final yield distribution of oil, gas, and coke, as well as the quality of the resulting bio-oil.

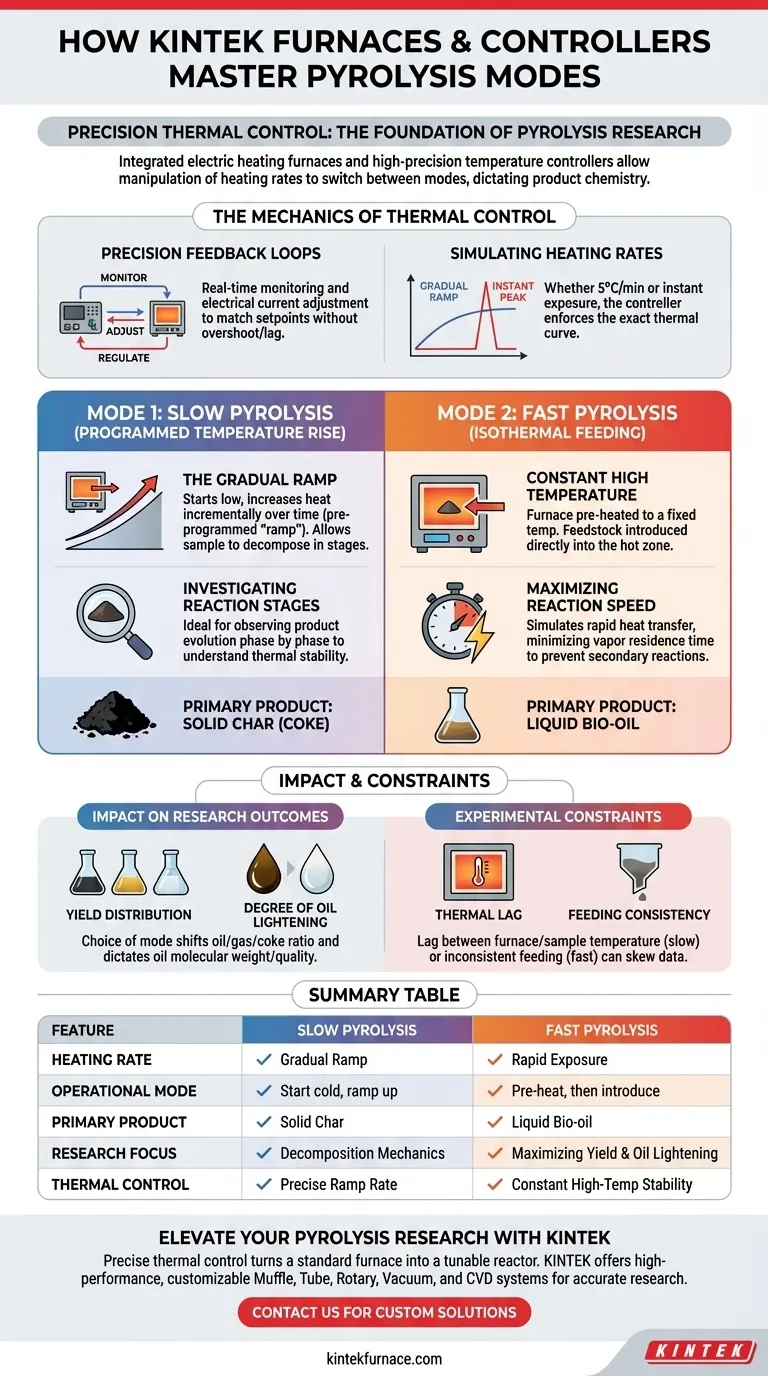

The Mechanics of Thermal Control

Precision Feedback Loops

The core enabler of this technology is the feedback loop provided by the temperature controller.

It continuously monitors the furnace's internal temperature and adjusts the electrical current in real-time. This ensures the actual temperature matches the setpoint without significant overshoot or lag.

Simulating Heating Rates

This precision allows the system to simulate exact heating rates.

Whether the experiment requires a gradual increase of 5°C per minute or an immediate exposure to peak temperatures, the controller enforces the necessary thermal curve.

Mode 1: Programmed Temperature Rise (Slow Pyrolysis)

The Gradual Ramp

In this mode, the furnace starts at a low temperature and increases heat incrementally over time.

The controller executes a pre-programmed "ramp," slowly elevating the temperature to a final setpoint. This allows the sample to undergo thermal decomposition in stages.

Investigating Reaction Stages

This mode is ideal for studying the evolution of products at specific temperature intervals.

It allows researchers to observe how the feedstock breaks down phase by phase, providing insight into the thermal stability of different components.

Mode 2: Isothermal Feeding (Fast Pyrolysis)

Constant High Temperature

In this mode, the furnace is pre-heated and maintained at a specific, constant temperature (isothermal) by the controller.

The feedstock is then introduced directly into this hot zone, usually via a specialized feeding mechanism.

Maximizing Reaction Speed

This simulates fast pyrolysis conditions, where rapid heat transfer is critical.

The goal is to minimize the residence time of vapors to prevent secondary reactions, which is crucial for maximizing liquid yield.

Impact on Research Outcomes

Yield Distribution

The choice of mode dramatically shifts the ratio of oil, gas, and coke produced.

Slow pyrolysis generally favors char (coke) production, while fast pyrolysis (isothermal) is typically optimized for liquid (oil) production.

Degree of Oil Lightening

The heating mode also dictates the degree of oil lightening.

By controlling how quickly the feedstock cracks, researchers can influence the molecular weight distribution of the resulting oil, affecting its viscosity and quality.

Understanding Experimental Constraints

Thermal Lag

A common pitfall is assuming the sample temperature equals the furnace temperature.

In programmed rise modes, there is often a lag between the heating element and the core of the sample. Precision controllers minimize this, but physical heat transfer limitations still apply.

Feeding Consistency

For isothermal feeding, the limitation is often mechanical rather than thermal.

If the "feeding" is not instantaneous or consistent, the sample experiences a temperature ramp rather than a flash heat, inadvertently creating a hybrid mode that skews data.

Making the Right Choice for Your Goal

To maximize the utility of your research system, align the furnace mode with your specific experimental objectives.

- If your primary focus is maximizing liquid yield: Utilize Isothermal Feeding to ensure rapid heat transfer and minimize secondary cracking.

- If your primary focus is analyzing decomposition mechanics: Utilize Programmed Temperature Rise to observe how yields change progressively across the temperature spectrum.

- If your primary focus is solid fuel (char) production: Utilize Programmed Temperature Rise with a slow ramp rate to promote carbonization.

Precise thermal control turns a standard furnace into a tunable reactor capable of dictating product chemistry.

Summary Table:

| Feature | Slow Pyrolysis (Programmed Rise) | Fast Pyrolysis (Isothermal Feeding) |

|---|---|---|

| Heating Rate | Gradual/Incremental Ramp | Rapid/Instantaneous Exposure |

| Operational Mode | Start cold, heat to setpoint | Pre-heat furnace, then introduce sample |

| Primary Product | Solid Char (Coke) | Liquid Bio-oil |

| Research Focus | Decomposition mechanics & stability | Maximizing yield & oil lightening |

| Thermal Control | Precise ramp rate execution | Constant high-temperature stability |

Elevate Your Pyrolysis Research with KINTEK

Precise thermal control is the difference between an average result and a breakthrough. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temperature furnaces—all fully customizable to meet your unique experimental needs.

Whether you require sophisticated ramp-rate programming for slow pyrolysis or stable isothermal zones for fast pyrolysis, our systems provide the accuracy your research demands. Contact us today to discuss your custom furnace solution and see how our expertise can optimize your product yields and reaction kinetics.

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is input voltage an important factor in selecting a muffle furnace? Ensure Safety and Performance for Your Lab

- Why are box type electric furnaces indispensable in industry and laboratories? Unlock Precision and Versatility in Thermal Processing

- How should the temperature be managed when using a muffle furnace? Master Precise Control for Safety & Accuracy

- How do the costs of industrial muffle furnaces and drying ovens compare? Understand the Price Gap and Choose Wisely

- What are the main applications of box type electric furnaces? Unlock Precision in Material Processing

- How is a muffle furnace used in heat treatment processes? Achieve Precise Material Transformations

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control