In heat treatment, a muffle furnace is used to execute critical processes like annealing, hardening, tempering, and normalizing. It does this by heating materials, typically metals and alloys, to precise temperatures in a highly controlled environment. This targeted heating fundamentally alters the material's internal structure to achieve desired properties such as increased hardness, improved ductility, or greater strength.

The defining feature of a muffle furnace isn't just its ability to reach high temperatures, but its use of an isolated chamber—the "muffle"—to provide extremely uniform, controlled heat. This separation between the heating elements and the material is what makes predictable and repeatable changes to a material's properties possible.

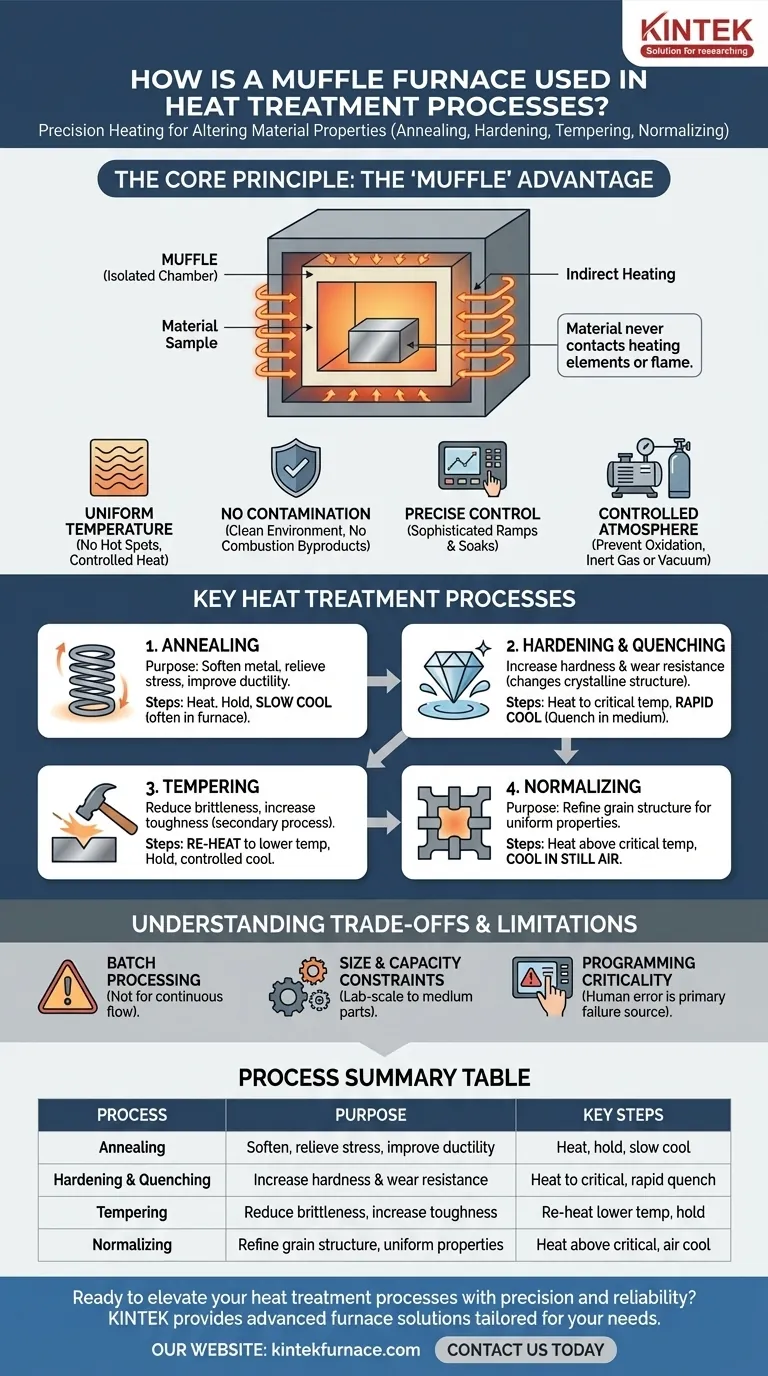

The Core Principle: Why a 'Muffle' is Critical

The term "muffle" refers to the furnace's design, which is central to its function in high-precision applications. Understanding this principle explains why it is a superior choice for heat treatment over simpler ovens.

What is a Muffle?

A muffle is an enclosed chamber, often made of ceramic, that contains the material being heated. This chamber is then heated from the outside by heating elements.

The material inside the muffle never comes into direct contact with the flame or heating elements.

The Benefit of Indirect Heating

This indirect heating method ensures exceptionally uniform temperature across the entire sample. There are no "hot spots" that could cause inconsistent results.

It also prevents contamination of the material from combustion byproducts (in fuel-fired models) or direct radiation damage from electric elements.

Achieving Precise Temperature Control

Modern muffle furnaces are equipped with sophisticated digital controllers. Combined with the uniform heating environment, this allows for very precise and stable temperature ramps and soaks.

This level of control is non-negotiable for heat treatment, where a deviation of even a few degrees can ruin the outcome.

Controlling the Atmosphere

Because the muffle is a sealed chamber, the atmosphere inside can be controlled. Air can be evacuated to create a vacuum or replaced with an inert gas like argon or nitrogen.

This prevents oxidation and scaling on the material's surface, which is crucial for maintaining surface finish and dimensional accuracy.

Key Heat Treatment Processes in a Muffle Furnace

A muffle furnace's precision makes it ideal for the most common metallurgical processes. Each process follows a specific heating and cooling profile to produce a different result.

Annealing

The goal of annealing is to soften metal, relieve internal stresses, and improve its ductility (ability to be deformed without fracturing).

This involves heating the material to a specific temperature, holding it there, and then cooling it very slowly, often by leaving it inside the furnace as it cools.

Hardening & Quenching

Hardening increases a metal's resistance to deformation and wear. The material is heated to a critical temperature to change its crystalline structure.

It is then rapidly cooled, or quenched, in a medium like water, oil, or air. This speed is what locks in the hard, brittle structure.

Tempering

A hardened part is often too brittle for practical use. Tempering is a secondary process used to reduce that brittleness and increase toughness.

The hardened part is re-heated to a much lower temperature and held for a specific time. This carefully relieves some of the internal stress from the hardening process.

Normalizing

Normalizing is used to refine the grain structure of a metal, making its mechanical properties more uniform and predictable. It creates a consistent baseline state before further hardening or machining.

The process involves heating the material above its critical temperature and then cooling it in still air, which is faster than annealing but slower than quenching.

Understanding the Trade-offs and Limitations

While powerful, a muffle furnace is not the solution for every scenario. Understanding its limitations is key to using it effectively.

Batch Processing vs. Continuous Flow

Muffle furnaces are batch processors. You load a part or a set of parts, run the cycle, and then unload them.

They are not suited for continuous, assembly-line-style manufacturing where parts are constantly moving through a heating zone. Other furnace designs, like tunnel or belt furnaces, serve that purpose.

Size and Capacity Constraints

Most muffle furnaces are designed for laboratory-scale work or the treatment of small- to medium-sized components.

Treating very large or heavy industrial parts requires massive, purpose-built industrial furnaces that may or may not use a muffle design.

The Critical Role of Programming

The primary source of failure in heat treatment is often human error, not equipment failure. An incorrect temperature, hold time, or cooling rate will produce the wrong material properties.

Successful heat treatment depends entirely on programming the correct thermal profile for the specific alloy and the desired outcome.

Making the Right Choice for Your Goal

Your choice of heat treatment process is dictated entirely by the final properties your material needs to have.

- If your primary focus is to soften metal and improve ductility: Annealing is your required process, demanding a slow, controlled cool-down.

- If your primary focus is to maximize hardness and wear resistance: You will use a hardening and quenching cycle, which requires rapid cooling.

- If your primary focus is to reduce brittleness in a hardened part: Tempering is the necessary follow-up step, using lower, precise temperatures.

- If your primary focus is to refine the grain structure for uniform properties: Normalizing provides a consistent baseline for further treatment or use.

Ultimately, the muffle furnace serves as the precise instrument needed to reliably perform these metallurgical transformations.

Summary Table:

| Process | Purpose | Key Steps |

|---|---|---|

| Annealing | Soften metal, relieve stress, improve ductility | Heat to specific temperature, hold, slow cool in furnace |

| Hardening & Quenching | Increase hardness and wear resistance | Heat to critical temperature, rapid cool (quench) in medium |

| Tempering | Reduce brittleness, increase toughness in hardened parts | Re-heat to lower temperature, hold for specific time |

| Normalizing | Refine grain structure for uniform properties | Heat above critical temperature, cool in still air |

Ready to elevate your heat treatment processes with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for laboratories and industrial applications. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our furnaces can enhance your material properties and efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation