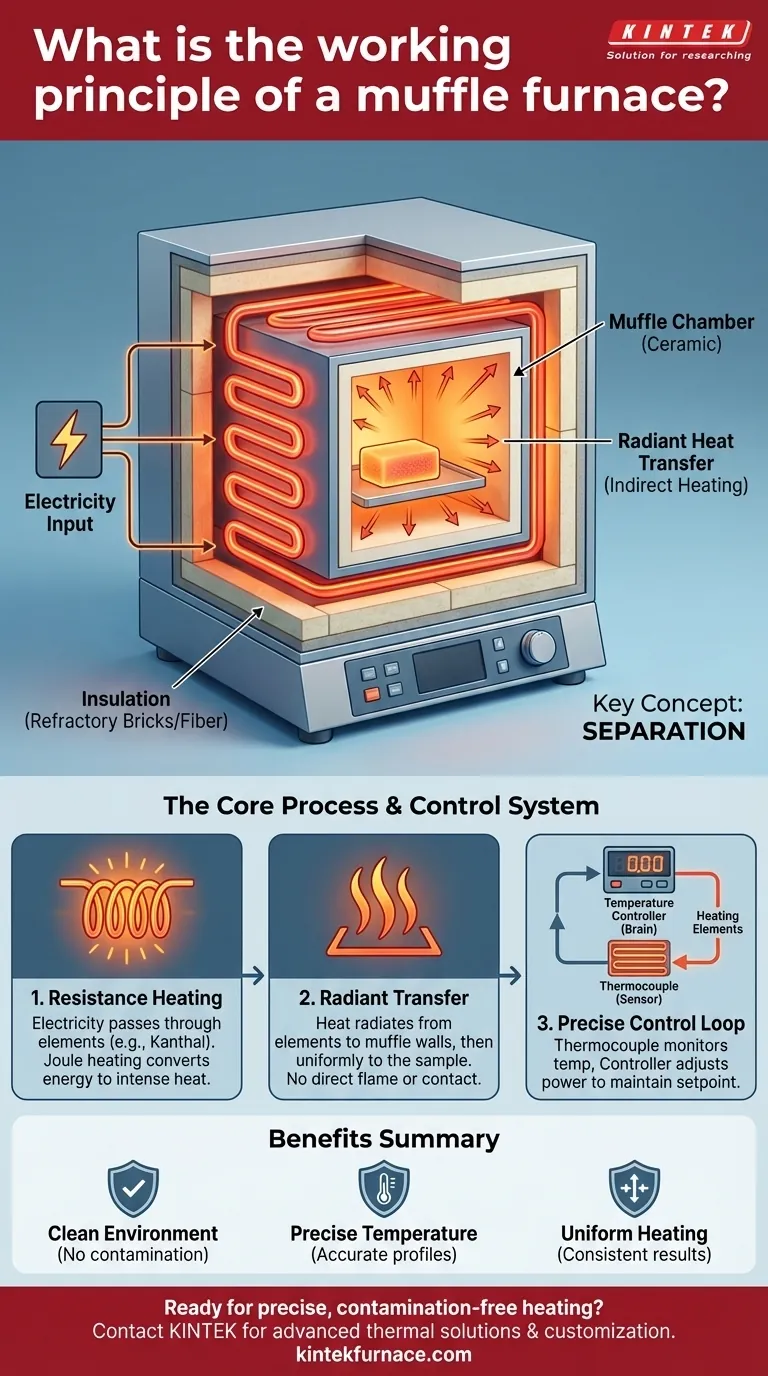

At its core, a muffle furnace operates on the principle of indirect heating. It uses electrical energy to heat a chamber from the outside, allowing materials inside to reach very high, precise temperatures without being exposed to flames, combustion byproducts, or the heating elements themselves.

The central concept is separation. A muffle furnace creates a clean, controlled heating environment by isolating the sample in a "muffle," or chamber, which is heated externally by radiation. This prevents contamination and allows for extremely precise temperature regulation.

The Core Principle: Indirect Electrical Heating

The defining characteristic of a modern muffle furnace is that the heat source never touches the material being heated. This is achieved through a specific sequence of energy conversion and transfer.

From Electricity to Heat: Resistance Heating

A muffle furnace converts electrical energy into thermal energy. This process is known as resistance heating or Joule heating.

Electricity is passed through heating elements made of a high-resistance material, such as Kanthal or nickel-chromium alloys. As the current struggles to pass through this resistance, the elements become extremely hot.

The "Muffle": An Insulated Chamber

The heating elements are embedded within the walls of the furnace, surrounding a separate, isolated chamber. This inner chamber is the "muffle."

The muffle is typically made from a high-temperature ceramic material that can withstand thermal shock and remain chemically inert. Its purpose is to physically separate the sample from the heating elements.

Heat Transfer via Radiation

The intense heat generated by the elements radiates inward, warming the walls of the muffle chamber.

The chamber walls, in turn, radiate this heat uniformly throughout the interior space. This ensures the sample is heated evenly from all sides without any direct contact with the heat source.

The Control System: Achieving Precision

A muffle furnace is not just a hot box; it is a precision instrument. This precision comes from a closed-loop control system that constantly monitors and adjusts the temperature.

The Sensor: The Thermocouple

A thermocouple acts as the furnace's thermometer. It is a robust temperature sensor placed inside the heating chamber to get an accurate reading of the internal temperature.

The Brain: The Temperature Controller

The thermocouple sends its reading to the temperature controller. This is the electronic brain of the system.

The controller constantly compares the actual temperature inside the muffle to the desired temperature (setpoint) programmed by the user. If the temperature is too low, it sends more power to the heating elements. If it's too high, it cuts the power.

The Insulation: Maintaining Thermal Efficiency

The entire assembly is housed within a heavily insulated case. This insulation, often made of refractory bricks or ceramic fiber, minimizes heat loss to the surrounding environment. This makes the furnace more energy-efficient and helps it maintain a stable temperature.

Understanding the Distinctions and Trade-offs

While the principle is straightforward, it's important to understand what a muffle furnace is—and what it isn't.

Electric vs. Fuel-Fired Furnaces

While some older or specialized industrial furnaces burn fuel, the vast majority of modern laboratory muffle furnaces are electric. Electric heating provides far superior temperature control, cleanliness, and repeatability, which are critical for scientific and technical applications.

Atmosphere Control as a Limitation

A standard muffle furnace operates by heating the air inside the chamber. This is perfectly suitable for many applications like ashing, sintering, or heat-treating in an air atmosphere.

However, if a process requires an inert atmosphere (like nitrogen or argon) or a reactive one, a more specialized furnace with gas inlet and outlet ports is required.

How to Apply This to Your Goal

Your specific application will determine which aspect of the furnace's operation is most important to you.

- If your primary focus is high-purity processing: The key benefit is the indirect heating within the muffle, which prevents any contamination from the heating elements or combustion.

- If your primary focus is precise heat treatment: The crucial component is the thermocouple and controller system, which guarantees your material follows a precise temperature profile.

- If your primary focus is repeatable material testing: The combination of uniform radiant heat and tight temperature control ensures that every sample is processed under identical conditions.

Understanding these principles empowers you to use a muffle furnace not just as a heater, but as a precise tool for material transformation.

Summary Table:

| Principle Component | Function | Key Benefit |

|---|---|---|

| Heating Elements | Convert electricity to heat via resistance (Joule heating). | Generates high temperatures safely. |

| Muffle Chamber | Ceramic chamber isolating the sample from heating elements. | Ensures a clean, contamination-free environment. |

| Heat Transfer | Heats the chamber via radiation for uniform sample heating. | Provides even, consistent thermal treatment. |

| Control System (Thermocouple & Controller) | Monitors temperature and adjusts power to maintain setpoint. | Delivers precise, repeatable temperature profiles. |

| Insulation | Minimizes heat loss to the environment. | Improves energy efficiency and temperature stability. |

Ready to leverage precise, contamination-free heating for your lab?

At KINTEK, we don't just sell furnaces; we provide advanced thermal solutions. Leveraging our exceptional R&D and in-house manufacturing, we offer a range of high-temperature furnaces, including Muffle, Tube, and Vacuum Furnaces, complemented by strong deep customization capabilities to meet your unique experimental requirements precisely.

Contact us today to discuss how our expertise can help you achieve superior results in your material testing, heat treatment, or research applications.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation