In a muffle furnace, the atmosphere's primary role is twofold: it acts as a medium to transfer heat uniformly to the sample and provides a controlled chemical environment, protecting the material from direct contact with heating elements and unwanted contaminants. This ensures both thermal consistency and chemical purity during high-temperature processing.

The atmosphere inside a muffle furnace is not merely empty space; it is an active and critical component. Its function is to guarantee that the sample is heated evenly from all sides while simultaneously dictating the chemical reactions—or lack thereof—that can occur at high temperatures.

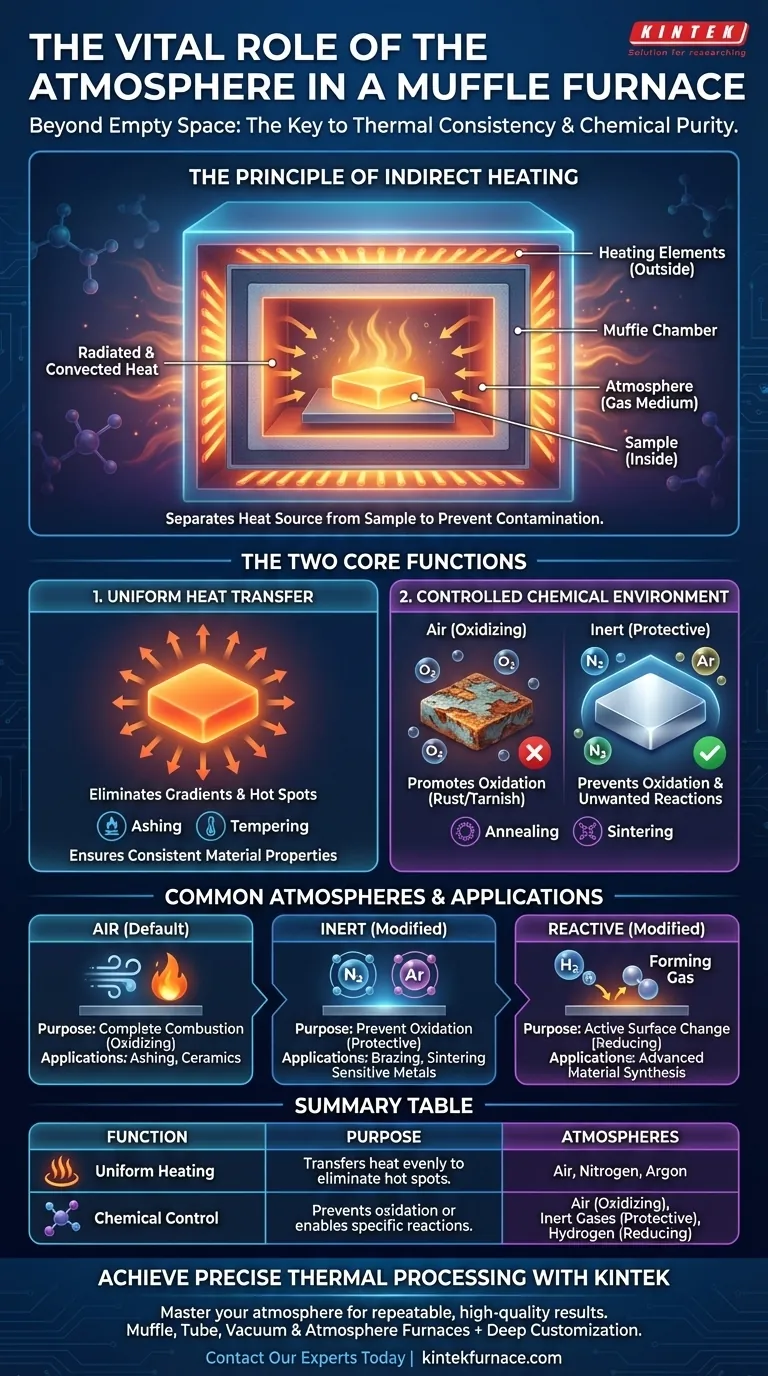

The Principle of Indirect Heating

To understand the atmosphere's role, you must first understand how a muffle furnace works. It is fundamentally an indirect heating system.

Separating the Heat Source from the Sample

A muffle furnace contains a chamber, or "muffle," made of a heat-resistant material. The heating elements, which generate the high temperatures, are located outside of this chamber.

This design intentionally separates the heat source from the material being processed. This prevents contamination from combustion by-products (in fuel-fired furnaces) or direct radiation hot-spots from electrical elements.

The Atmosphere as a Heat Transfer Medium

The heating elements heat the walls of the muffle. The muffle then radiates and convects this heat into the atmosphere—typically air or a specific gas—sealed inside the chamber.

This heated atmosphere then envelops the sample, transferring thermal energy to it evenly from all directions.

The Two Core Functions of the Furnace Atmosphere

The atmosphere inside the muffle chamber serves two distinct but equally important purposes.

Function 1: Ensuring Uniform Heating

A static, contained atmosphere is excellent at distributing heat. By heating the sample from all sides simultaneously, it eliminates the temperature gradients and hot spots common with direct heating methods.

This uniformity is critical for processes like annealing, tempering, and ashing, where consistent material properties are the primary goal.

Function 2: Providing a Controlled Chemical Environment

The atmosphere also dictates the chemical interactions that take place. By managing the gas inside the muffle, you can either prevent or encourage specific reactions.

The most common goal is to prevent oxidation. Many materials, especially metals, will rapidly oxidize (rust or tarnish) at high temperatures when exposed to oxygen. The muffle allows for the air to be replaced with an inert gas to prevent this.

Common Atmospheres and Their Applications

The "right" atmosphere depends entirely on the process goal. The choice is a deliberate one that directly impacts the outcome of the thermal processing.

The Default Atmosphere: Air

For many common applications like determining the ash content of a sample or certain ceramics processing, a standard air atmosphere is sufficient and often necessary. The oxygen in the air is required to facilitate complete combustion of the organic material.

Modified Atmospheres for Sensitive Materials

For processing sensitive metals or advanced materials, oxygen is a contaminant. In these cases, the chamber is purged of air and filled with a specific gas.

- Inert Atmospheres (Nitrogen, Argon): These gases are non-reactive. They are used to create a protective environment that prevents oxidation and other unwanted chemical changes during processes like brazing or sintering.

- Reactive Atmospheres (Hydrogen, Forming Gas): In some advanced applications, a reactive gas is introduced to actively change the surface of the material, such as reducing surface oxides.

Making the Right Choice for Your Process

Understanding the role of the atmosphere allows you to select the correct conditions for your specific application.

- If your primary focus is ashing or simple drying: A standard air atmosphere is all you need, as its main role is to provide uniform heat.

- If your primary focus is annealing or brazing metals: You require an inert atmosphere (like nitrogen or argon) to prevent destructive oxidation at high temperatures.

- If your primary focus is advanced material synthesis: You may need a specific reactive gas atmosphere to control the chemical transformation of your sample.

Ultimately, mastering the furnace atmosphere is fundamental to achieving precise, repeatable results in high-temperature material processing.

Summary Table:

| Function | Purpose | Common Atmospheres |

|---|---|---|

| Uniform Heating | Transfers heat evenly to eliminate hot spots and temperature gradients. | Air, Nitrogen, Argon |

| Chemical Control | Prevents oxidation or enables specific reactions by managing the gas composition. | Air (Oxidizing), Inert Gases (Protective), Hydrogen (Reducing) |

Achieve Precise Thermal Processing with KINTEK's Advanced Furnace Solutions

Mastering your furnace atmosphere is key to repeatable, high-quality results. Whether your application requires simple ashing in air or complex material synthesis under a controlled gas, KINTEK has the expertise and technology to meet your exact needs.

Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Ready to optimize your high-temperature processes? Contact our experts today to discuss how a KINTEK furnace can deliver the perfect atmosphere for your application.

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment