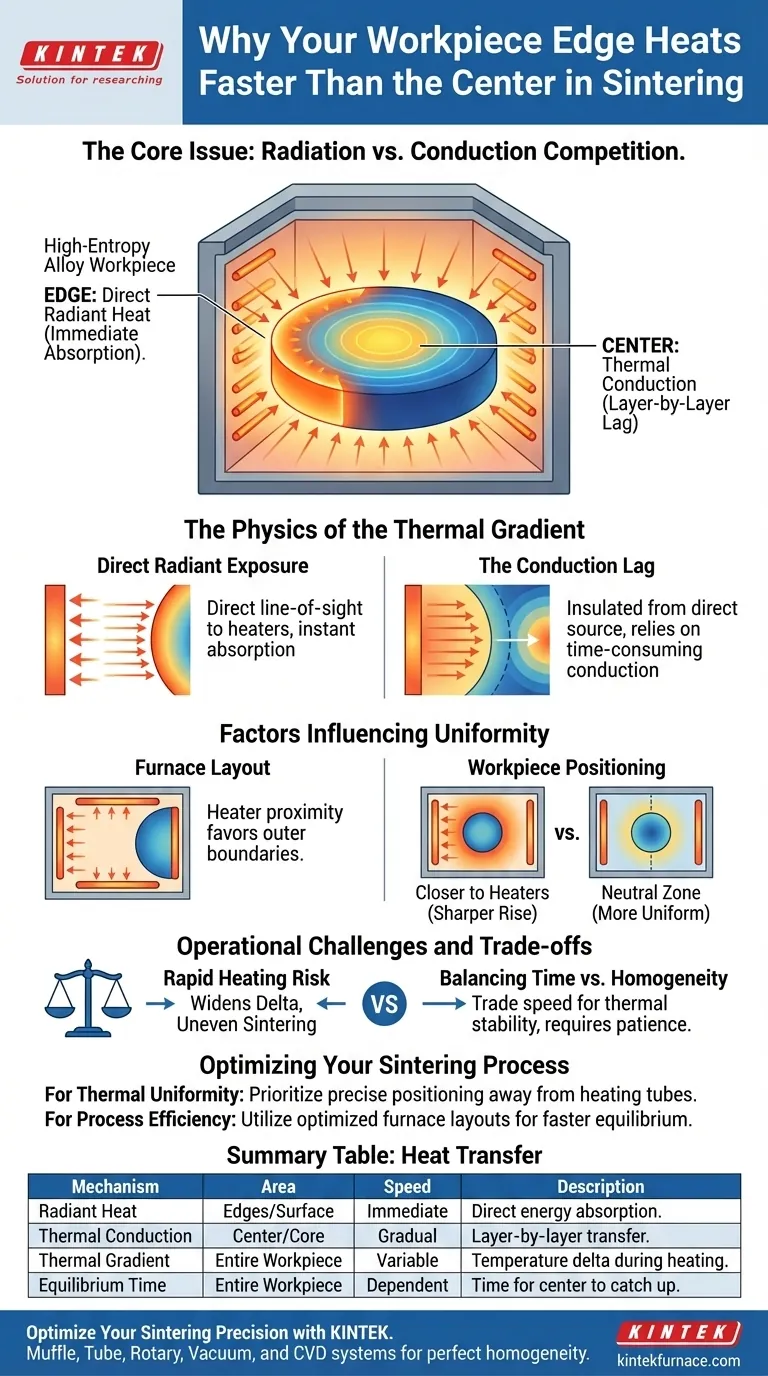

The temperature disparity between the edge and center of a workpiece is driven by the physics of heat transfer within the furnace environment. The edges of the high-entropy alloy absorb radiant energy directly and immediately from the heating elements, while the center must wait for that thermal energy to travel inward via conduction.

The core issue is a competition between two heat transfer mechanisms: rapid surface radiation versus slower internal conduction. The edges heat up instantly due to direct line-of-sight with the heaters, while the center lags behind, creating a temporary thermal gradient until equilibrium is reached.

The Physics of the Thermal Gradient

Direct Radiant Exposure

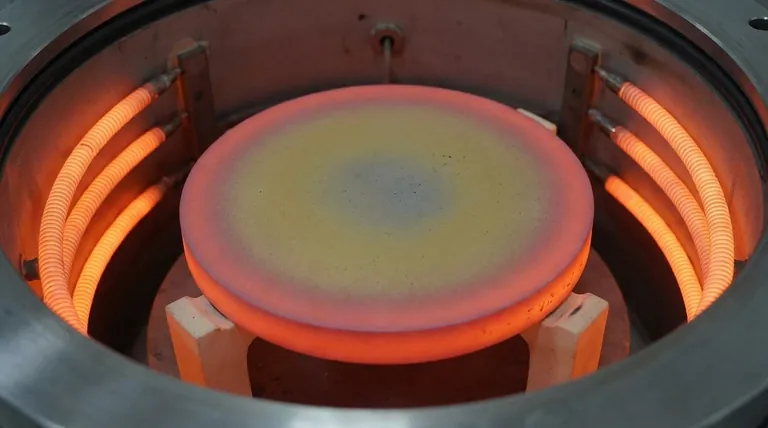

In a sintering furnace, the primary heat source is the heating elements located on the walls.

The edges and sides of your workpiece have a direct "line of sight" to these heaters. Consequently, they absorb radiant heat immediately and intensely as soon as the temperature rises.

The Conduction Lag

While the surface heats up via radiation, the center of the workpiece remains insulated from the direct source.

The core relies on thermal conduction to receive heat. This process involves energy transferring layer by layer from the hot outer surface to the cooler interior.

This physical transfer of energy takes time. This "inherent time delay" means the center will always be cooler than the surface during the active heating phase.

Factors Influencing Uniformity

Furnace Layout

The physical arrangement of the furnace plays a critical role in how severe this gradient becomes.

Heaters are typically positioned on the walls, naturally favoring the outer boundaries of the workspace.

Workpiece Positioning

Where you place the alloy within the chamber alters its exposure.

A workpiece positioned closer to the heating tubes will experience a sharper rise in edge temperature compared to one placed in a "neutral" zone.

Operational Challenges and Trade-offs

The Risk of Rapid Heating

Trying to reach the sintering temperature too quickly exacerbates the problem.

If the furnace ramps up temperature faster than the material can conduct heat, the delta between the edge and the center widens. This can lead to uneven sintering or thermal stress within the high-entropy alloy.

Balancing Time vs. Homogeneity

Precision furnaces are designed to minimize the "thermal equilibrium time"—the time it takes for the center to catch up to the edge.

However, achieving perfect uniformity requires patience. You trade process speed for thermal homogeneity, allowing the conduction process to stabilize the internal temperature.

Optimizing Your Sintering Process

To mitigate these gradients and ensure high-quality sintering of high-entropy alloys, you must focus on equipment configuration and placement.

- If your primary focus is thermal uniformity: Prioritize the precise positioning of the workpiece away from the immediate proximity of heating tubes to reduce the intensity of direct radiation.

- If your primary focus is process efficiency: Utilize furnaces with optimized heating tube layouts designed to shorten the time required for thermal equilibrium.

By understanding that the center always lags behind the edge, you can adjust your heating profiles to allow the necessary time for conduction to complete its work.

Summary Table:

| Heat Transfer Mechanism | Area Affected | Speed | Description |

|---|---|---|---|

| Radiant Heat | Edges / Surface | Immediate | Direct line-of-sight energy absorption from furnace heating elements. |

| Thermal Conduction | Center / Core | Gradual | Layer-by-layer energy transfer from the hot surface to the cooler interior. |

| Thermal Gradient | Entire Workpiece | Variable | The temperature delta between surface and core during the heating phase. |

| Equilibrium Time | Entire Workpiece | Dependent | The time required for internal conduction to match surface temperature. |

Optimize Your Sintering Precision with KINTEK

Don't let thermal gradients compromise the integrity of your high-entropy alloys. KINTEK provides industry-leading high-temperature solutions backed by expert R&D and manufacturing. Our Muffle, Tube, Rotary, Vacuum, and CVD systems are designed to minimize thermal equilibrium time and ensure perfect homogeneity for your most sensitive materials.

Whether you need a standard setup or a fully customizable furnace tailored to your unique research needs, our team is ready to help you achieve superior results.

Ready to enhance your lab's efficiency and heating accuracy?

Contact KINTEK today to discuss your project requirements!

Visual Guide

References

- Yuchen Wang, Haisheng Fang. Research and optimization of temperature uniformity of high-precision muffle furnace. DOI: 10.1088/1742-6596/3009/1/012076

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why is precise temperature control in a muffle furnace critical for 1250°C homogenization of AlCoCrFeNi alloys?

- What role does a laboratory muffle furnace play in the determination of phosphorus content? Essential Dry Ashing Guide

- What is the purpose of using a muffle furnace to fire Al2O3 ceramic shells at 1050°C? Enhance Strength and Purity

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What makes muffle furnaces suitable for high-temperature applications? Achieve Clean, Controlled Heat for Purity

- What roles do programmable laboratory high-temperature furnaces play in calcium perrhenate single crystal preparation?

- Why is an industrial high-temperature furnace required for chemical activation? Achieve 700°C Precision for Carbon

- What is the working temperature of a muffle furnace? Find the Right Heat for Your Lab