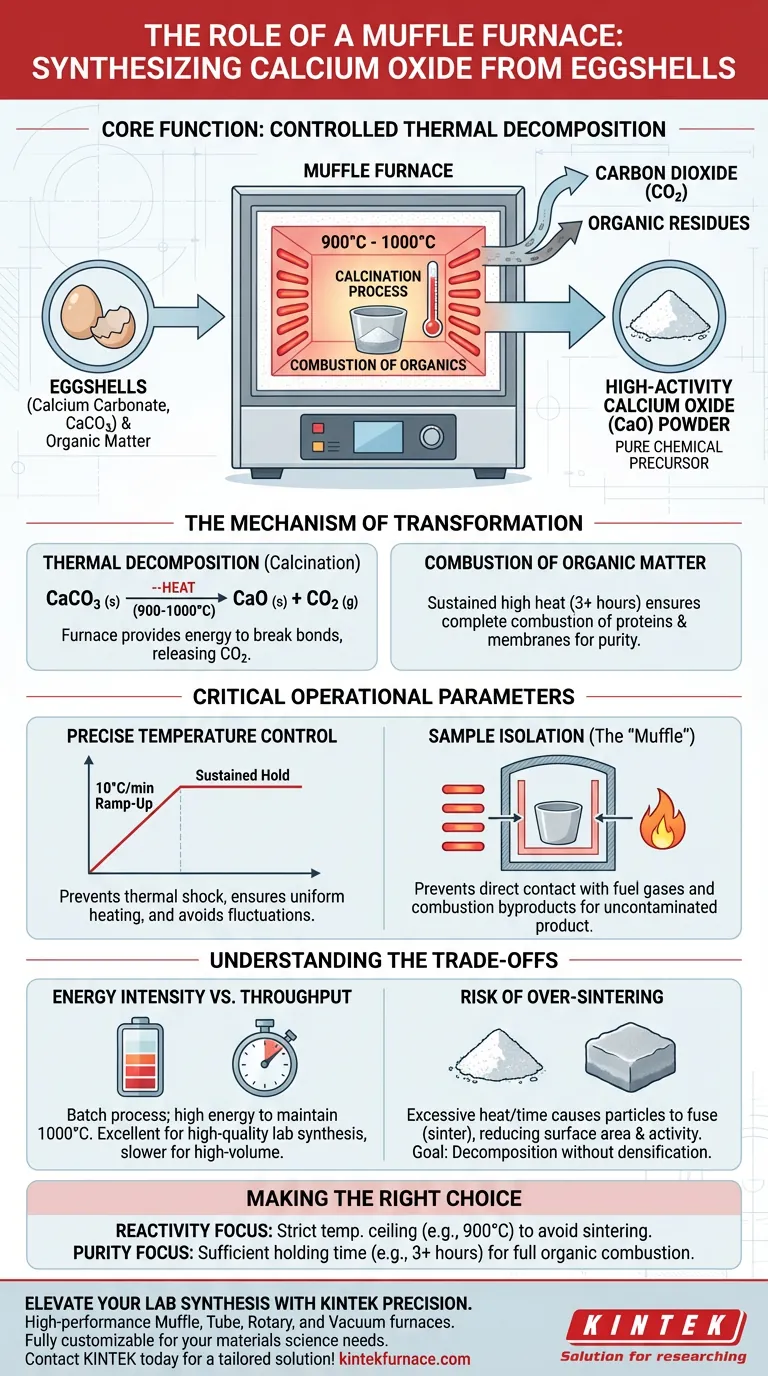

The primary function of a muffle furnace in this synthesis is to drive the thermal decomposition of calcium carbonate (CaCO3) found in eggshells. By creating a controlled environment capable of reaching temperatures between 900°C and 1000°C, the furnace breaks chemical bonds to release carbon dioxide, leaving behind high-activity calcium oxide (CaO) powder.

The muffle furnace acts as a precision calcination reactor. It ensures the complete conversion of biomass waste into pure chemical precursors by maintaining strict temperature profiles and isolating the sample from combustion contaminants.

The Mechanism of Transformation

Thermal Decomposition

The core chemical process facilitated by the furnace is calcination. Eggshells are primarily composed of calcium carbonate.

To convert this stable compound into reactive calcium oxide, the furnace provides the energy required to break the molecular bonds. At temperatures typically maintained between 900°C and 1000°C, the calcium carbonate decomposes, releasing carbon dioxide gas as a byproduct.

Combustion of Organic Matter

Beyond the mineral conversion, the muffle furnace plays a critical role in purification. Eggshells naturally contain organic membranes and proteins.

The sustained high heat—often applied for durations such as three hours—ensures the complete combustion of these organic substances. This results in a final product that is free of biological residues, yielding a high-purity ceramic powder.

Critical Operational Parameters

Precise Temperature Control

Success in synthesis relies on the furnace's ability to follow a specific heating curve. The primary reference highlights the importance of controlling the heating rate, such as rising 10°C per minute.

This gradual increase prevents thermal shock and ensures uniform heating throughout the sample. Once the target temperature is reached, the furnace's control system maintains the heat level to prevent temperature fluctuations that could lead to incomplete synthesis.

Sample Isolation

A defining feature of the muffle furnace is the "muffle" itself—a chamber that separates the object being heated from the heating elements and combustion byproducts.

Because the eggshell powder does not come into direct contact with fuel gases or combustion residues, the resulting calcium oxide remains uncontaminated. This isolation is essential when the CaO is intended for sensitive applications, such as synthesizing hydroxyapatite for biomedical use.

Understanding the Trade-offs

Energy Intensity vs. Throughput

While muffle furnaces provide exceptional control and purity, they are batch-processing tools that consume significant energy to reach and maintain 1000°C.

Rapid cooling is often difficult due to the insulation required to hold these temperatures. This limits the speed of sequential runs, making the process excellent for high-quality laboratory synthesis but potentially slower for high-volume industrial production.

The Risk of Over-Sintering

Temperature precision is a double-edged sword. While high heat is necessary for calcination, excessive temperatures or prolonged holding times can lead to sintering.

If the powder sinters, the particles fuse into a solid mass, significantly reducing the surface area and chemical activity of the calcium oxide. The goal is to achieve decomposition without accidentally densifying the powder into a ceramic block.

Making the Right Choice for Your Goal

When configuring a muffle furnace for eggshell calcination, align your parameters with your specific end-use requirements:

- If your primary focus is Chemical Reactivity: Prioritize a strict temperature ceiling (e.g., 900°C) to ensure full decomposition without inducing sintering, keeping the powder "active."

- If your primary focus is Material Purity: Ensure the holding time is sufficient (e.g., 3+ hours) to fully combust all organic membranes and residues within the biomass.

The muffle furnace is the definitive tool for converting raw biological waste into precise chemical reagents through controlled thermal processing.

Summary Table:

| Parameter | Role in Synthesis | Benefit |

|---|---|---|

| Temperature (900-1000°C) | Drives CaCO3 decomposition | Complete conversion to active CaO |

| Controlled Heating Rate | 10°C/min ramp-up | Prevents thermal shock & ensures uniformity |

| Sample Isolation | Separation from heating elements | Prevents contamination from combustion |

| Sustained Holding Time | 3+ hours of high heat | Ensures total combustion of organic residues |

| Precise Insulation | Maintains thermal stability | Prevents under-calcination or over-sintering |

Elevate Your Lab Synthesis with KINTEK Precision

Transform biomass waste into high-activity chemical precursors with ease. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, and Vacuum furnaces designed for rigorous calcination and sintering protocols. Whether you are synthesizing hydroxyapatite for biomedical use or developing ceramic powders, our systems provide the precise temperature profiles and contamination-free environments your research demands. All our laboratory high-temp furnaces are fully customizable to meet your unique materials science needs.

Ready to optimize your thermal processing? Contact KINTEK today for a tailored solution that brings expert efficiency to your laboratory.

Visual Guide

References

- Budi Prayitno, Siska Ayu Kartika. THE EFFECT OF CALCINATION TEMPERATURE AND HOLDING TIME ON STRUCTURAL PROPERTIES OF CALCIA POWDERS DERIVED FROM EGGSHELL WASTE. DOI: 10.29303/ipr.v8i1.450

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of a high-temperature Muffle Furnace in the two-step heat treatment of PTFE-coated Nickel Foam?

- What are the main components of a muffle furnace? Key Parts for Precision High-Temp Control

- What is the structure of a box type electric furnace? Uncover the Core Components for Precise Heating

- What is the function of a box muffle furnace in air annealing? Master Tin Oxide Catalyst Synthesis

- How is a muffle furnace utilized during the raw material preparation stage? Optimize Your Lab Results Today

- What are the environmental requirements for muffle furnace nanocrystallization of Fe-based alloys?

- What is the specific role of a muffle furnace in the preparation of corn straw biochar? Optimize Pyrolysis Success

- How does an industrial muffle furnace facilitate the chemical activation of clay? Unlock High-Performance Zeolites